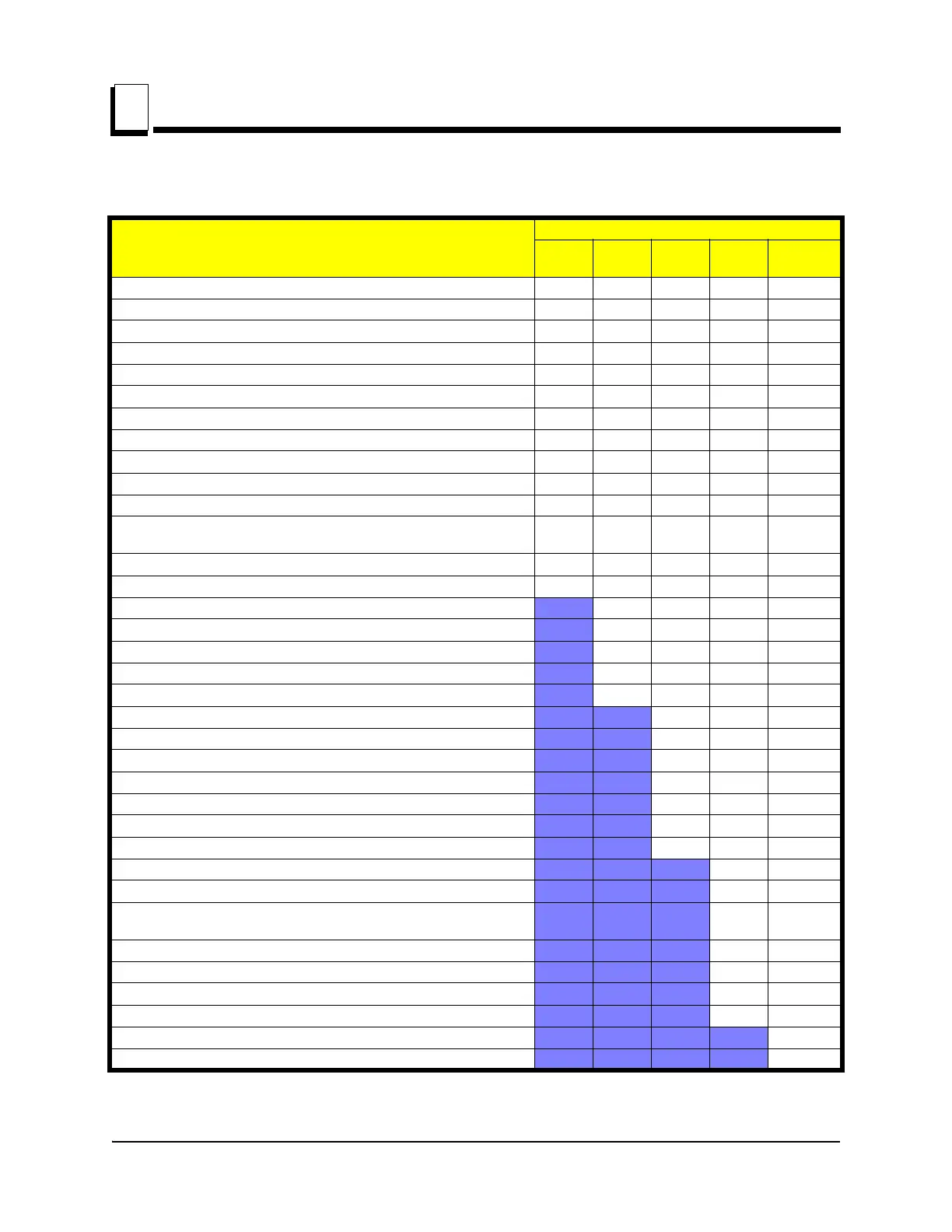

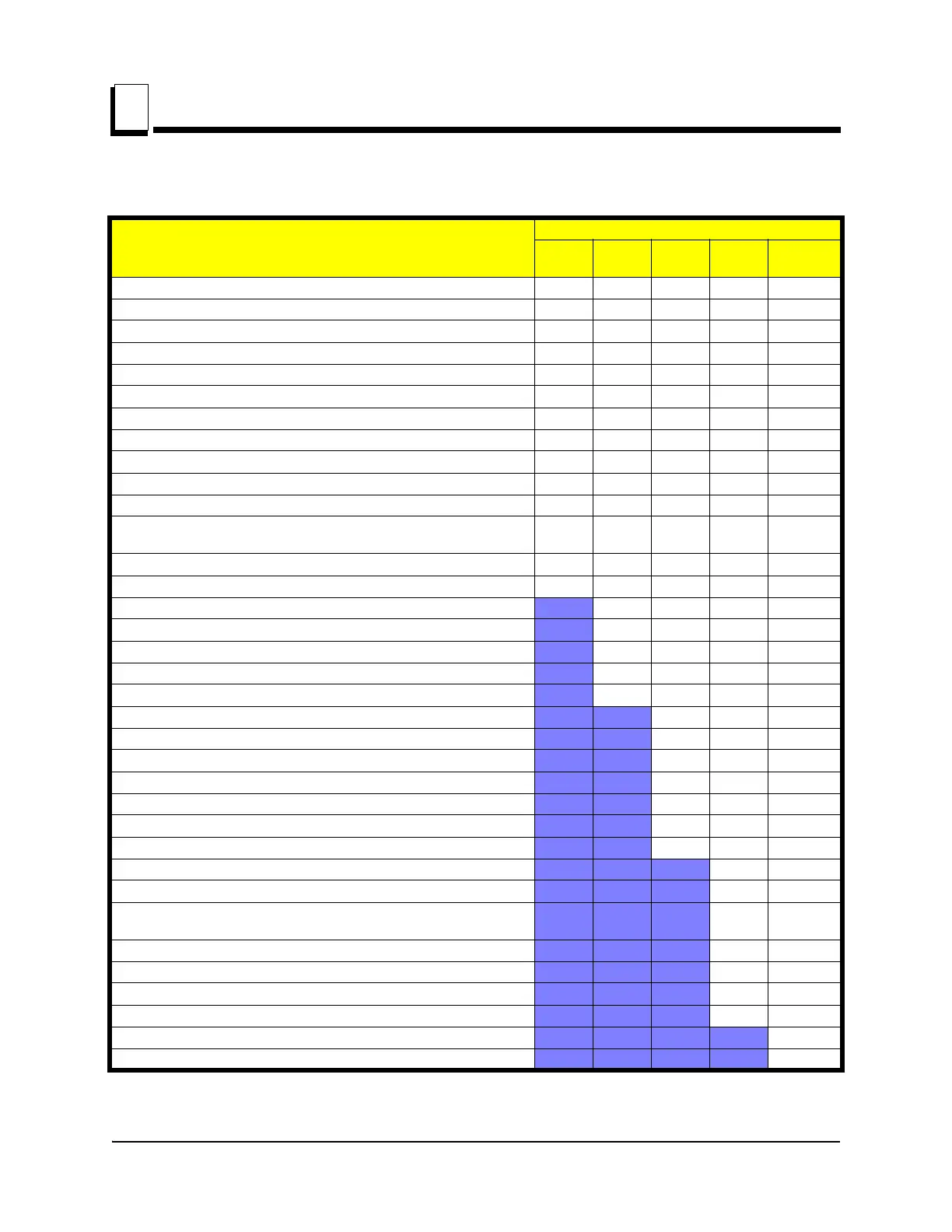

Maintenance

Articulator Maintenance Chart

5

5-5 Lastec//021819 Maintenance

5.7 Articulator Maintenance Chart

MAINTENANCE PROCEDURE CHECKLIST (HOURS OF OPERATION)

8 HRS 25

HRS

50

HRS

500

HRS

ANNUAL

Visually Inspect All Pneumatic Tires For Indication of Low Air Pressure

Grease All Wheel Shaft Pivot Collars

Verify Proper Anti-Scalp Wheel Settings

Grease All PTO Grease Fittings

Inspect Tension & Condition Of All Belts

Inspect All Blades & Blade Hardware

Inspect Condition & Grease Seals of All Spindle Bearings

Inspect Split Tapered Bushing Mounting Hardware

Verify That All Discharge Chutes are Free Of Debris

Verify That All Hardware is Securely Fastened & in Good Condition

Verify That All Safety Covers are In Place & Securely Fastened

Verify That All Warning Labels & Decals a

re Properly Installed, Visible &

Legible

Verify Proper Installation of the PTO Shaft and Shield Retaining Chains

Verify That the Articulator is Properly & Securely Mounted to Tractor

Complete the 8-hours Maintenance Schedule Checklist

Grease All Gauge Wheel Hubs

Grease Pull Bar Collar

Lubricate the PTO Guick-disconnect Pin or Twist Sleeve

Lubricate All Non-Fitted Wear Points

Complete the 8-hour and 25-hour Maintenance Checklist

Grease All Blade Spindle Bearing Housing

Inspect the Gearbox Area For Any Oil Leakage

Check the Gearbox Oil Level

Inspect All Wheel Bearing For Wear, Damage, Debris & Proper Installation

Inspect All Bronze Bushings

Grease All Grease Fittings

Complete the 8-hour, 25-hour & 50-hour Maintenance Checklist

Change the Gearbox Oil

Inspect All Blade Spindle Bearings for Wear, Damage, Debris & Proper

Installation

Replace the Pull Bar Collar Bushing

Verify the Proper Installation & Condition of the Pull Pin

Repack All Wheel Bearings

Inspect All Component Parts and Wear Points

Install the 621 Articulator Rebuild Kit (040290)

Complete the 8-hour, 25-hour, 50-hour & 500-hour Maintenance Checklist

Loading...

Loading...