3

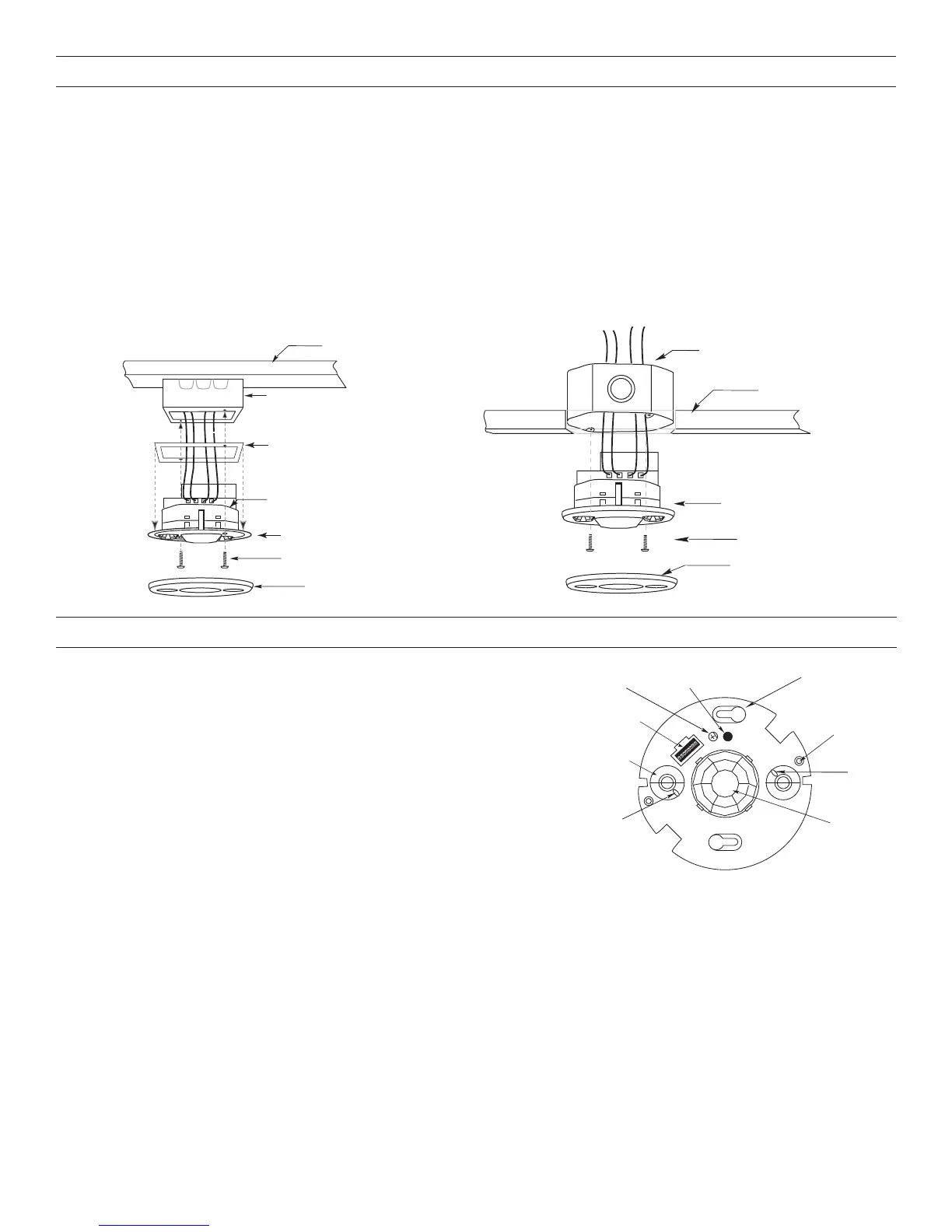

Using a 4-Inch Square Junction Box

1. Pull the line voltage wires into the J-Box through the conduit

knockout.

2. Run the wires through the CA-1 adapter then connect the

line voltage wires to the appropriate terminals on the sensor.

3. Align the CA-1 and the sensor with the J-Box so that the

mounting screw tabs on the box match the mounting holes

on the sensor’s rear housing and the CA-1.

4. Use two machine screws (included with the sensor) to attach

the sensor to the mounting tabs on the J-Box.

5. Snap the front cover onto the sensor.

Using an Octagonal J-Box

1. Pull the line voltage wires into the J-Box through the conduit

knockout.

2. Connect the line voltage wires to the appropriate terminals

on the sensor.

3. Loosen the appliance mounting screws attached to the J-Box

4. Align the sensor in the J-Box so that the mounting screws on

the box match the key holes on the sensor’s rear housing.

5. Push the sensor up into the J -Box and twist it so that the

mounting screws are seated in the keyhole slots.

6. Tighten the two screws to secure the sensor to the J-Box.

7. Snap the front cover onto the sensor.

* The

Junction

Box must

be at least

2.25” deep.

If it is not,

an extension

ring is

required.

2.25" Deep

*

Junction Box

Ceiling

Sensor

Screws

Front

Cover

Mounting to an Octagonal Junction Box

Rear Housing

4" Square

Wiremold #V5752 bo

Front Cover

Screws

CA-1 Adapter

Sensor Flange

Mounting to a 4” Square Wiremold V5752 box or 4”

Square Junction Box with Double-Gang Mudring

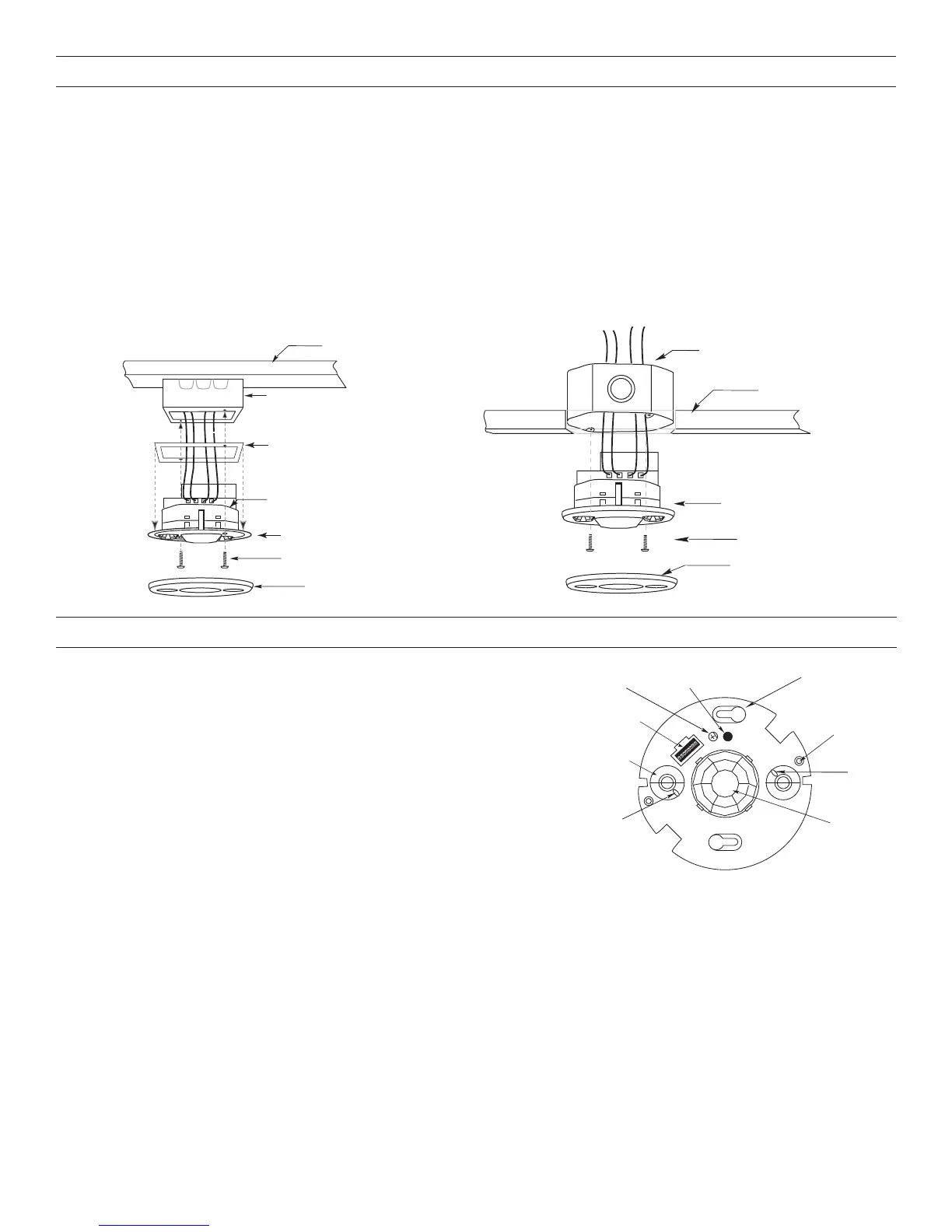

MOUNTING THE SENSOR

SENSOR ADJUSTMENT

NOTE: This unit is pre-set for basic operation as described in this guide.

Adjustment is optional.

The sensors are factory preset to allow for quick installation in most

applications. Verification of proper wiring or coverage, or customizing the

sensor’s settings can be done using the following procedures. To make

adjustments, open the Front Cover with a small screwdriver.

There is a 30 second warm-up period when power is first applied.

Before making adjustments, make sure the office furniture is installed,

lighting circuits are turned on, and the HVAC systems are in the overridden/

on position. VAV systems should be set to their highest airflow. Set the Logic

Configuration and Time Delay to the desired settings. See the DIP switch

Configuration Chart.

To Test Occupancy Sensors

1. Ensure the Time Delay is set for Test Mode* using the “Test Mode/20 minutes” setting. (DIP switches 1, 2, & 3 are OFF).

2. Ensure that the Light Level is at default (maximum). Press and hold the pushbutton for 5 seconds or until the Green LED flashes

rapidly. Wait 10 seconds for the flashing to stop.

3. Ensure that the Ultrasonic Sensitivity trimpot is set to about 70%, clockwise.

4. Remain still. The red and green LEDs should not flash. The lights should turn off after 5 seconds. (If not, see “Troubleshooting”).

5. Move around within the coverage area. The lights should come on. Adjust the Ultrasonic Sensitivity as necessary to provide the

desired coverage (Green LED indicates activation from the ultrasonic sensor).

When testing and adjustment is complete, reset DIP Switches and Light Level to the desired settings, and replace the cover on the

sensor.

• Test Mode is a temporary state that starts when you first set the sensor’s DIP switches for the “Test Mode/20 minutes” (switches 1,

2, 3 OFF). If you need to invoke the Test Mode and the DIP switches are already set for Test Mode/20 minutes, toggle DIP switch 1

ON then back to the OFF position. This provides a 10 minute test period. During the test period, the Time Delay is only 5 seconds.

Keyhole slots

(for mounting to

4" octagonal box)

Double gang

mudring

mounting holes

Light level pushbutton

DIP switches

PIR lens

Ultrasonic

sensitivity

trimpot

ON

1

2

3

4

5

6

7

8

ECE

Ultrasonic

transducer

cones

Ultrasonic

activity

LED (Green)

PIR Activity

LED (Red)

Loading...

Loading...