45

45

RTJ400 User Guide

Chapter 10

Box Joint Procedures - 3/8"

A

B

A

A

A

C

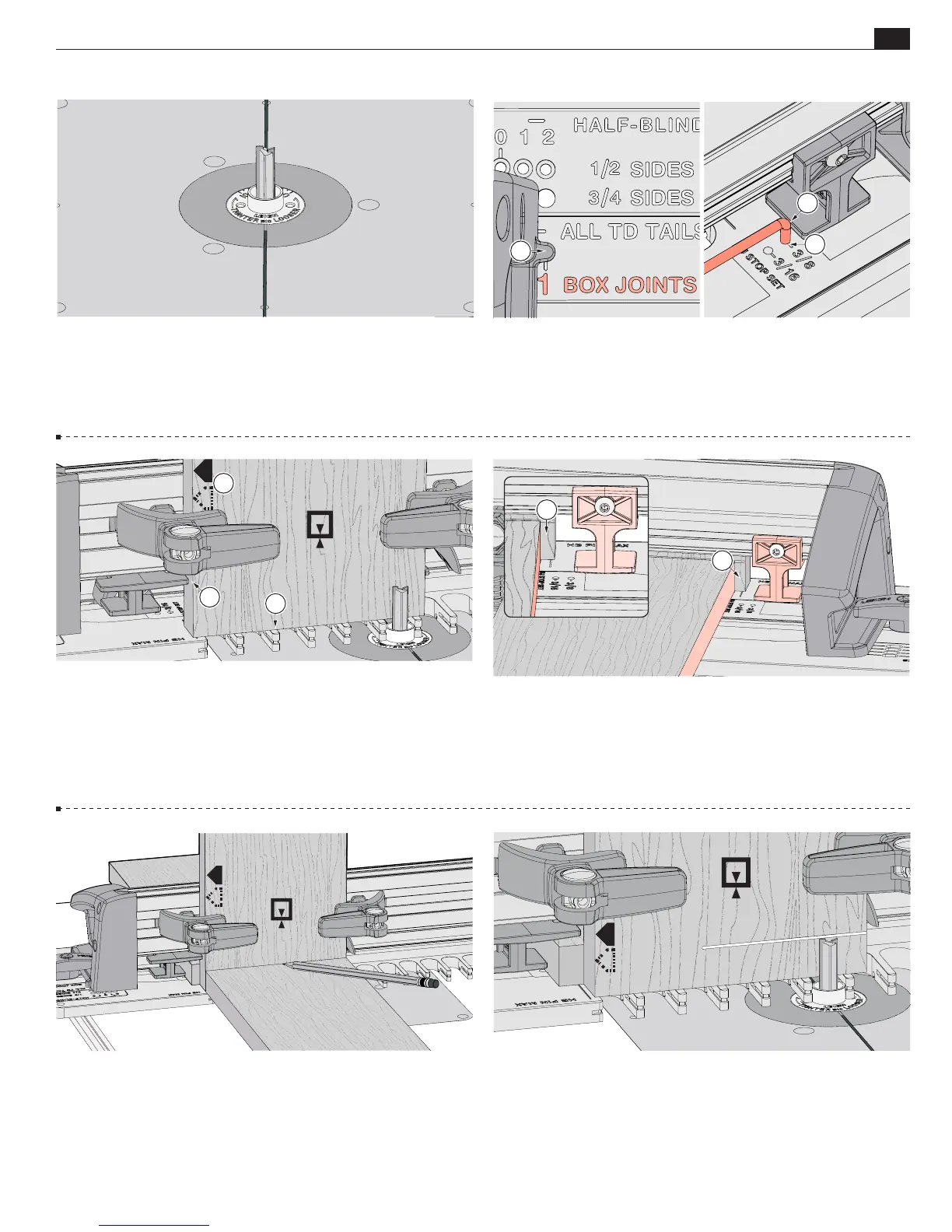

10-9 Insert the right frame pin in the

No.1 BOX JOINTS

hole

A

and the left frame pin in the

HALF-BLIND & BJ

slot. Latch the

frame. Put the short end of the stop rod into the

3/8" BJ STOP SET

hole

B

. Slide the sidestop to lightly touch the rod

C

and tighten

the sidestop. Store the stop rod in the ¾" slot.

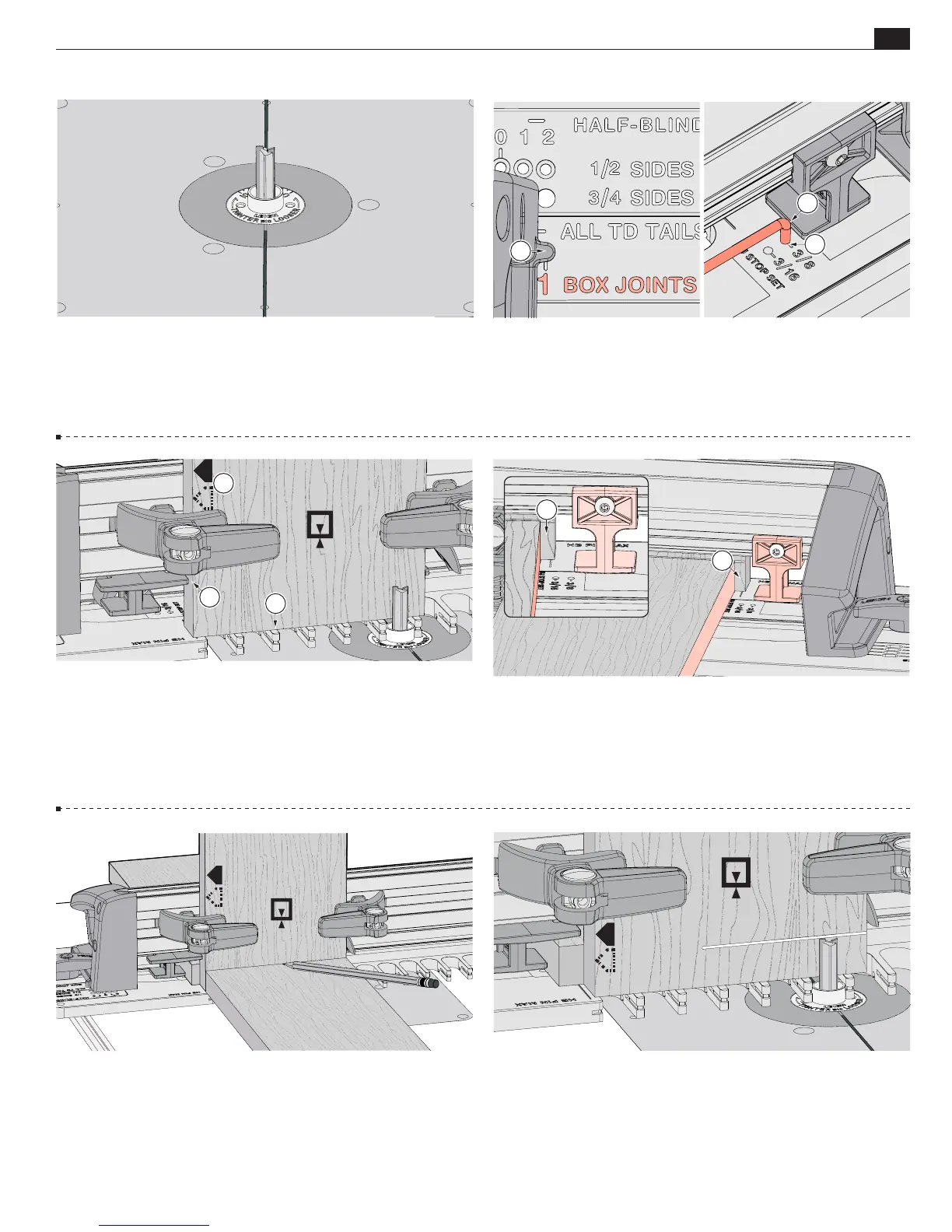

10-12 Place the end of a socket board on the template and

pencil a line on the pin board.

10-13 Adjust the bit to the center of the pencil line. Double

check that the bit still rotates freely.

IMPORTANT: Bit height

determines the flushness of the joint, so set your bit properly

the first time.

Adjustments for flushness are at the end of the

chapter.

10-8 With the router unplugged, install the supplied ⅜" Leigh

143-500 bit. For cleaner routing use the optional ⅜" Leigh

173-500 (HSS) or 173-500C (solid carbide) spiral upcut bit,

available at leighjigs.com.

Make sure the bit spins freely before

connecting the power.

10-11 Position a backer board " [1.5mm] away from the

edge of the pin board

A

. This prevents the backer board from

interfering with the sidestop when the frame is repositioned in

the second step. The backer board stays in place for the complete

procedure.

Note: Clamp removed for clarity.

10-10 Clamp pin board 1 flush on the template

A

with the side

edge against the sidestop

B

.

Always keep the same side edge

of the board to the sidestop when routing box joints

C

.

If the

board width is only slightly narrower than the chart width, center

the board over the template, clamp in place and move the sidestop

against the board.

C

B

Loading...

Loading...