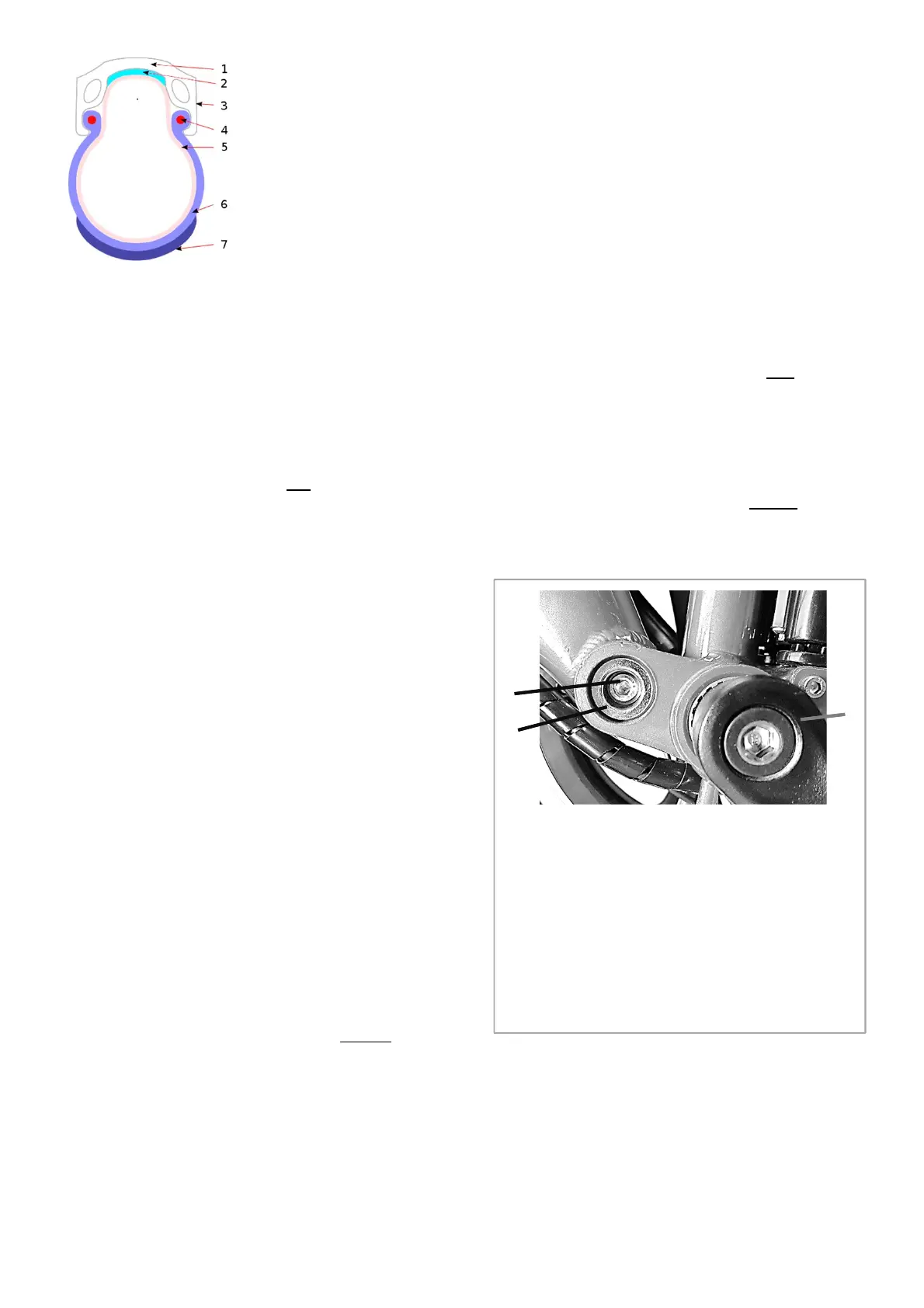

FigureT1:Cross‐sectionoftyreandrim:1:rim,2:rimstrip,3:rimbrakingsurface,4:beadcore,5:

innertube,6:casing,7:tread.Imagesource:Wikipedia,AuthorDeerwood.

Wheels: When changing a tyre or tube make sure that a rim strip is installed covering all spoke

holes and nipples to protect the tube from puncture. Inspect the spokes and make sure the

wheel is not wobbly. Clean rims every month with a moist rag and water to allowrimbrakesto

perform well. Check the rim for wear every month. Replace rim if it is worn or has signs of

damage. To check wheel hub bearings lift wheel off ground and spin it by hand. There should be

no unusual noise. Try to move wheel left and right. The bearings shouldn't be loose. If there are

issues have wheel replaced or repaired by a professional.

WARNING! A worn rim may cause the wheel to malfunction while riding causing you to fall.

Replacing tyres: Standard tyres consist of an outer tyre and a separate inner tube (Figure T1). Ifthetubeispuncturedit

needs to be replaced or patched. Make sure tube is same size as old tube. To remove tyres use your hands or a suitable tyre

lever available at bike shops. Do not use sharp objects like a screwdriver as they may damage the rim, tyre and tube. To

remove a wheel follow the instructions in this manual. Rim brakes need to be released first to allow wheel to be removed.

To remove tyre and tube, fully deflate inner tube and move tyre bead to centre of rim. Use tyre levers to lift one bead core

across the rim. Start opposite the valve as the valve will be in your way. You mayhavetousethreelevers.Takecarenotto

damage tyre or tube. Do this around the whole wheel until one bead is completely outside the rim. Remove tube, then

remove second bead from rim.

To install tyres and new tube, first carefully check the rim for any damage, cracks or sharp objects. Make sure rim strip is

installed correctly. Inflate tube until it takes shape, however don’t fully inflate it. Place it inside tyre, insert valve stem

through opening in rim and insert one bead using your hands into the rim around the whole wheel. Take care not to damage

the tube. Then, using your hands push the tube into the centre of the rim around the whole wheel. Insert second bead into

rim by hand. If it is too difficult, carefully use tyre lever without pinching the tube. Push stem of valve through opening in rim

and inflate tyre to half pressure. Check around wheel if tube is correctly on inside and tyre on outside. Adjust if necessary.

Deflate tube again to prevent pinching. Finally inflate to pressure recommended on tyre wall.

Theframeset(frameandfork)

• The frame is an important part of the bike to which many

parts such as the rear wheel, fork and seatpost attach. It

is critical to make sure that the frame is in good condition.

• If suspension is installed into the frame refer to the

respective section of this manual for suspension

maintenance.

• Do not expose frame to heat over 158° Fahrenheit (70°

Celcius).

• Onlycleanwithdamp,softrag,milddetergentandwater.

Only use small amounts of water to make rag damp.

• Avoid water intrusion into electrical components. Do not

spray any components with water or immerse into water.

• Do not use corrosive or harsh chemicals. After cleaning

wipe damp parts with dry, clean rag.

• Only use original seatposts with correct diameter, length

and correct minimum insertion marks. Installation of

seatpost with incorrect diameters, excessive length or too

short minimum insertion marks can damage the frame.

• When installing parts into threads on the frame make

sure the correct parts are used and that the threads on

the frame are not damaged, e.g. by over‐ or under‐

tightening. Clean all threads before installation, and insert

components at correct angle carefully by hand. If there is

too much resistance installing a part it may indicate cross‐

threading. Un‐screw part, re‐align and then re‐insert.

Only use tools to tighten part after it has been fully

inserted into thread by hand.

• Do not try to adjust frame by bending. Damaged frames

and forks should be reported and need to be replaced or

repaired.

Inspection: Check of the frame and fork before each ride for

scratches, deformation, chips or any other signs of damage.

Inspect fork in detail every year during headset service. This

should be done by a bike professional.

19

Rim,TyresandTubes

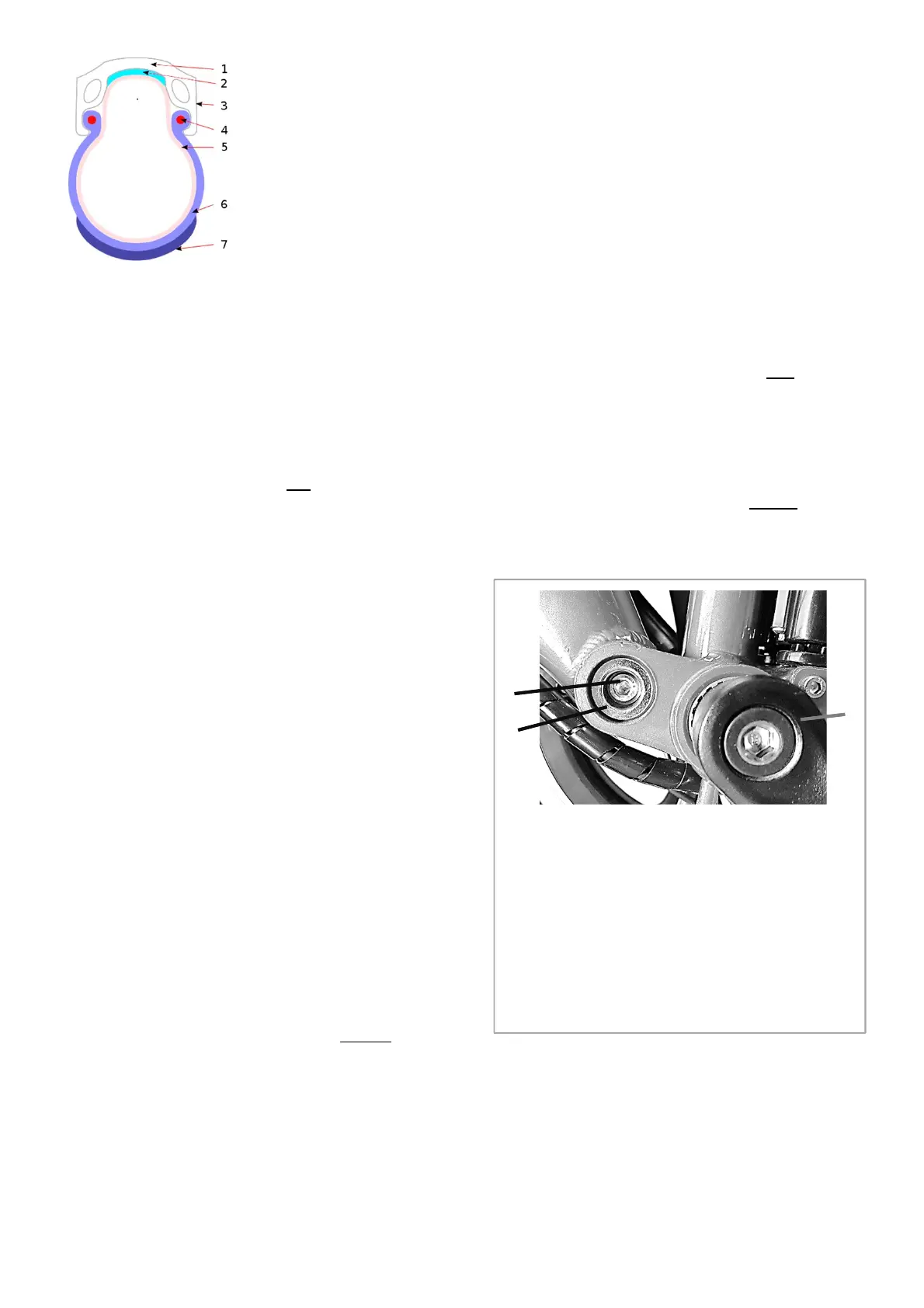

Figure FR1. SuperT and CrossX ebike only. LEFT side of

bike. The left pedal arm (8) is attached to the bottom

bracket. A few inches towards the front of bike there

is the bushing bolt (9). If there is a black rubber cover

remove the cover gently for example using the flat

end of a screwdriver. Make sure that the bushing bolt

(9) is tight using a 6mm Allen key. Tighten to 10 Nm.

The bushing bolt secures the left and right bushing at

the pivot hinge of the suspension frame. Ensure that

the bushings (10) are installed safely and not loose.

Inspect every 30 days.

9

8

Suspension

Check the bolts on all suspension parts and pivots

every 30 days. The suspension should not be able to

be fully compressed as that may cause the movement

to stop suddenly and may cause the rider to fall.

Accessories

Check your accessories, for example mudguards,

lights, kickstand, rack, chainguard every 30 days and

adjust attachment and alignment if necessary. The

rear rack is not centered however this does not affect

the function of the bike.

10

©LeitnerPtyLtd2019

Loading...

Loading...