Page 16

IV-HEATING SYSTEM SERVICE CHECKS

A-A.G.A./C.G.A. Certification

All units are A.G.A. and or C.G.A. design certified without

modifications. Refer to the 80UHG Operation and InstallaĆ

tion Instruction Manual Information.

B-Gas Piping

Gas supply piping should not allow more than 0.5"W.C.

drop in pressure between gas meter and unit. Supply

gas pipe must not be smaller than unit gas connection.

Compounds used on gas piping threaded joints should be

resistant to action of liquefied petroleum gases.

C-Testing Gas Piping

IMPORTANT

In case emergency shutdown is required, turn off

the main shutĆoff valve and disconnect the main

power to unit. These controls should be properly

labeled by the installer.

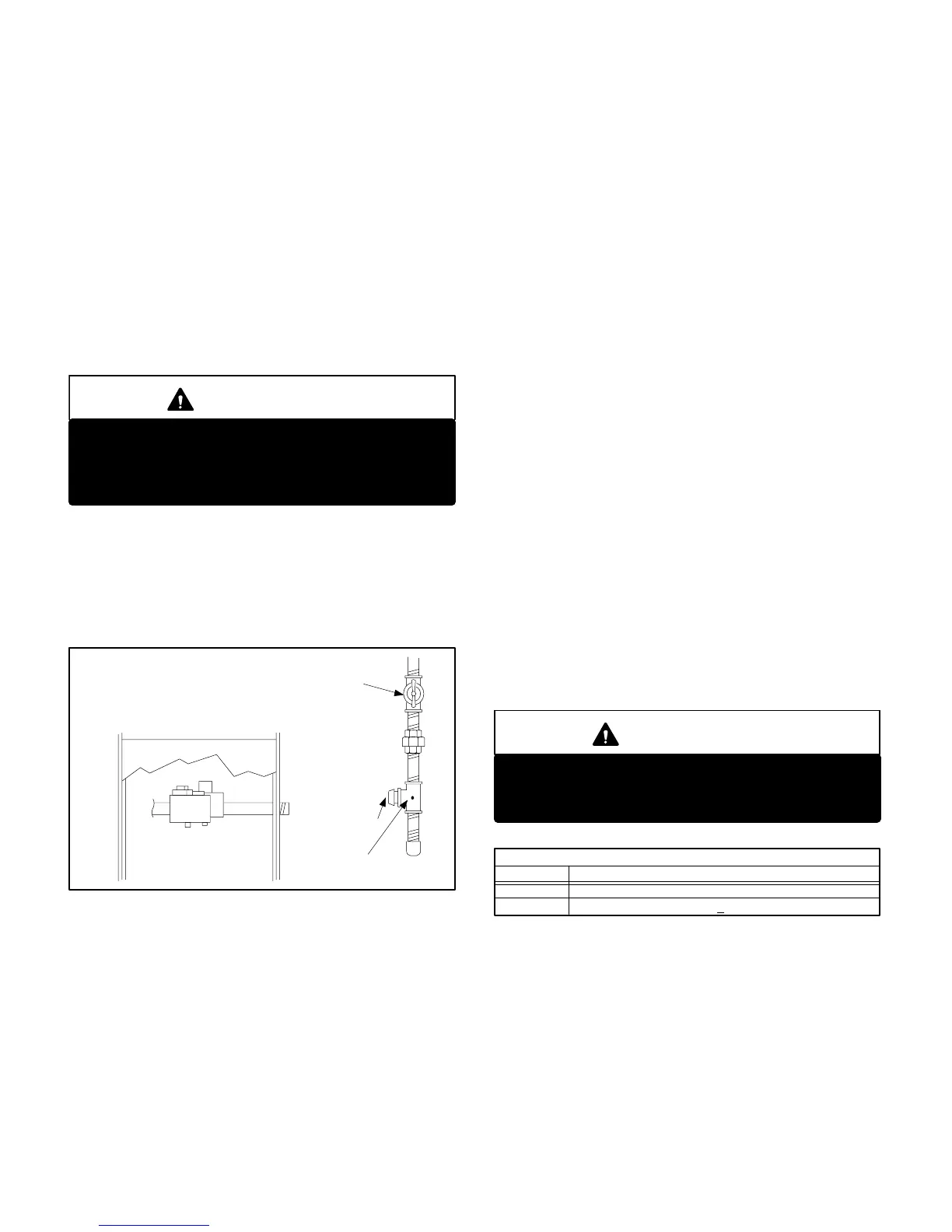

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valves can be damaged if

subjected to more than 0.5psig (14" W.C.). See figure 20. If

the pressure is equal to or less than 0.5psig (14"W.C.), use

the manual shut-off valve before pressure testing to isoĆ

late furnace from gas supply.

FIGURE 20

MANUAL MAIN SHUT-OFF VALVE

WILL NOT HOLD TEST PRESSURE

IN EXCESS OF 0.5 PSIG (14"W.C.)

GAS VALVE

CAP

GAS PIPING TEST PROCEDURE

FIELD PROVIDED

LINE PRESSURE TAP

When checking piping connections for gas leaks, use preĆ

ferred means. Kitchen detergents can cause harmful corroĆ

sion on various metals used in gas piping. Use of a specialty

Gas Leak Detector is strongly recommended. It is available

through Lennox under part number 31B2001. See Corp.

8411-L10, for further details.

Do not use matches, candles, flame or any other source of

ignition to check for gas leaks.

D-Testing Gas Supply Pressure

When testing supply gas pressure, connect test gauge to

inlet pressure tap (field provided). See figure 20. Check

gas line pressure with unit firing at maximum rate. Low

pressure may result in erratic operation or underfire. High

pressure can result in permanent damage to gas valve or

overfire. For 80UHG-45,60 and 75 BTUH natural gas

units, operating pressure at the unit must be a minimum

4.5"W.C. For the 80UHG-100 and 120 BTUH units, the opĆ

erating pressure must be a minimum of 5.0"W.C. For L.P.

gas units, operating pressure at unit gas connection must

be a minimum of 11.0" W.C.

On multiple unit installations, each unit should be checked

separately, with and without other units operating. Supply

pressure must fall within range listed in previous paraĆ

graph.

E-Check Manifold Pressure

After line pressure has been checked and adjusted, check

manifold pressure. Move pressure gauge to outlet presĆ

sure tap located on unit gas valve (GV1). Checks of manĆ

ifold pressure are made as verification of proper regulator

adjustment. Manifold pressure for the 80UHG can be meaĆ

sured at any time the gas valve is open and is supplying gas

to the unit. Normal manifold pressure for natural gas units is

3.5 in. W.C. For LP/propane gas the correct manifold presĆ

sure is 9.5 in. W.C.

IMPORTANT

For safety, connect a shutĆoff valve between the

manometer and the gas tap to permit shut off of

gas pressure to the manometer.

Operating Pressure (outlet) in. W.C.

TABLE 9

GAS VALVE REGULATION

3.5 +0 -0.3Natural

L.P. 9.5 + 0.5

Unit (Fuel)

The gas valve is factory set and should not require adĆ

justment. All gas valves are factory regulated. See

table 9. See specifications section of this manual for

High Altitude manifold pressure settings.

Loading...

Loading...