Page 26

10 - Is pressure switch closed? Obstructed ue will

cause unit to shut o at pressure switch. Check ue

and outlet for blockages.

11 - Are ame rollout switches tripped? If ame rollout

switches are tripped, call the service technician for

inspection.

Heating Sequence Of Operation (follow steps below)

1 - When thermostat calls for heat, combustion air

blower starts.

2 - Combustion air pressure switch proves blower

operation. Switch is factory-set and requires no

adjustment.

3 - After a 15-second prepurge, the hot surface ignitor

energizes.

4 - After a 20-second ignitor warm-up period, the gas

valve solenoid opens. A 4-second trial for ignition

period begins.

5 - Gas is ignited, ame sensor proves the ame, and

the combustion process continues.

6 - If ame is not detected after rst ignition trial, the

ignition control will repeat steps 3 and 4 four

more times before locking out the gas valve

(“WATCHGUARD” ame failure mode). The ignition

control will then automatically repeat steps 1 through

6 after 60 minutes.

7 - To interrupt the 60-minute “WATCHGUARD” period,

move thermostat from “Heat” to “OFF” then back to

“Heat.” Heating sequence then restarts at step 1.

Gas Pressure Adjustment

Gas Flow (Approximate)

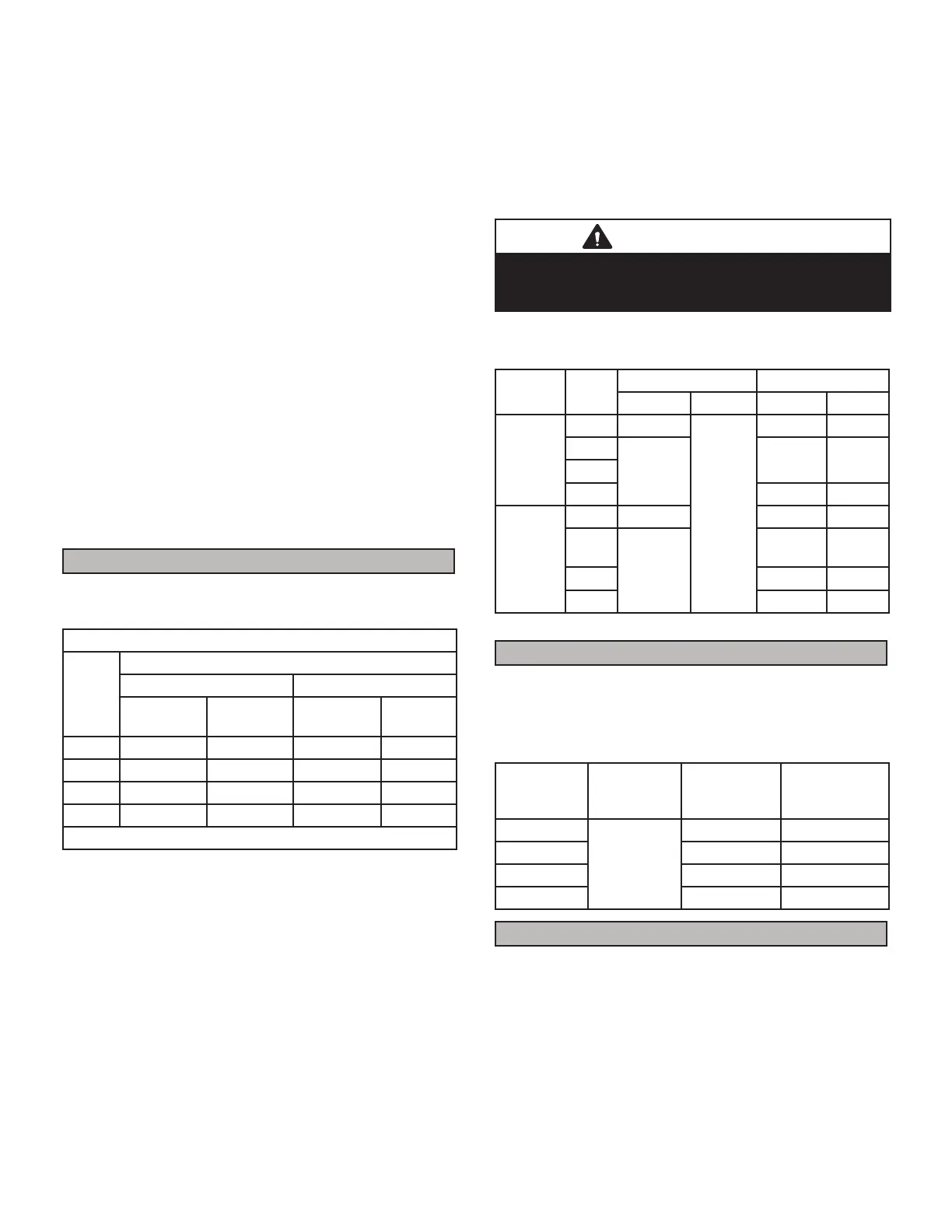

TABLE 8

GAS METER CLOCKING CHART

Unit

Seconds for One Revolution

Natural LP/Propane

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

Dial

-040 90 180 n/a n/a

-060 60 120 150 300

-080 45 90 112 224

-100 36 72 n/a n/a

Natural-1000 btu/cu ft LP/Propane - 2500 btu/cu ft

Furnace should operate at least 5 minutes before check-

ing gas ow. Determine time in seconds for two revolu-

tions of gas through the meter. (Two revolutions assures a

more accurate time.) Divide by two and compare to time in

TABLE 8. Remove temporary gas meter if installed.

NOTE - To obtain accurate reading, shut o all other gas

appliances connected to meter.Supply Pressure Mea-

surement

On multiple unit installations, each unit should be checked

separately, with and without units operating. Supply pres-

sure must fall within range listed in TABLE 9.

Check Manifold Pressure

1 - Remove the threaded plug from the outlet side of

the gas valve and install a eld-provided barbed

tting. Connect measuring device “+” connection to

barbed tting to measure manifold pressure.

Start unit and allow 5 minutes for unit to reach

steady state.

2- After allowing unit to stabilize for 5 minutes, record

manifold pressure and compare to value given in

TABLE 9. Make manifold adjustment if necessary

3 - Shut unit o and remove manometer as soon as an

accurate reading has been obtained.

4 - Restart unit and check for any gas leaks. Seal any

leaks if found.

IMPORTANT

For safety, connect a shut-o valve between the

manometer and the gas tap to permit shut o of gas

pressure to the manometer.

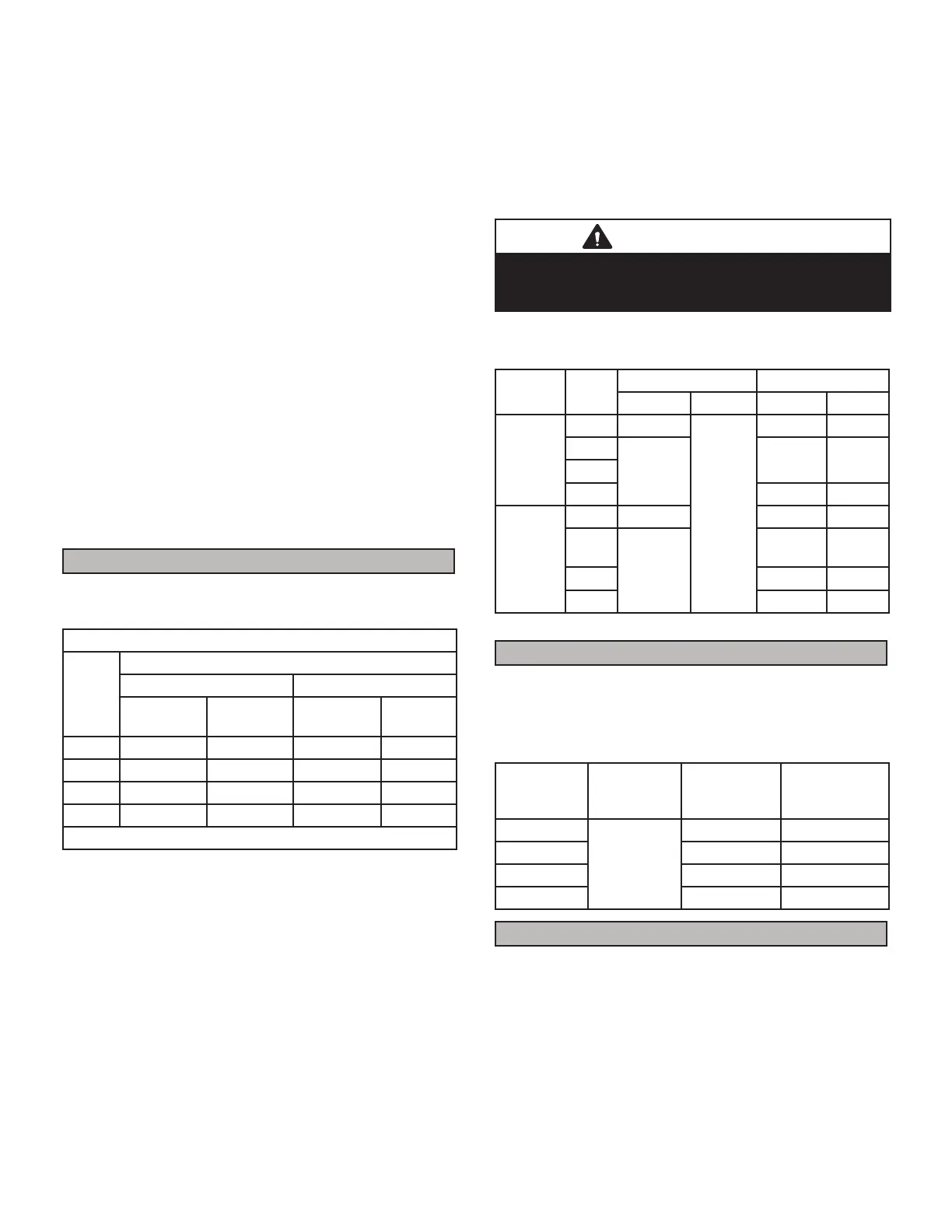

TABLE 9

Supply Line and Manifold Pressure (inches w.c.)

Altitude

ft

Unit

Natuarl LP/Propane

Manifold Supply Manifold Supply

0-4500 ft

-040 1.6-2.2

4.5-10.5

N/A N/A

-060

3.0-3.8

3.4-3.8

11.0-

13.0

-080

-100 N/A N/A

4501-

7500 ft

-040 1.4-2.0 N/A N/A

-060

2.5-3.3

2.5-3.3

11.0-

13.0

-080 N/A N/A

-100 N/A N/A

Proper Combustion & LP/Propane Conversion Kis

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas ow rate before checking com-

bustion. Take combustion sample beyond the ue outlet

and compare to the table below.

TABLE 10

Unit CO2% Nat CO2% LP

LP

Conversion

Kit

-040

6.5 - 7.5

N/A N/A

-060 7.5 - 9.0 20P40

-080 7.5 - 9.0 20P41

-100 N/A N/A

High Altitude

Units may be installed at altitudes up to 7,500 ft. above

sea level. See Table 9 for de-rate manifold values. Units

installed at altitude of 4501 - 7,500 feet require a pressure

switch change which can be ordered separately. Table 11

lists pressure switch requirements at high altitude. The

combustion air pressure switch is factory-set and requires

no adjustment.

Loading...

Loading...