Page 4

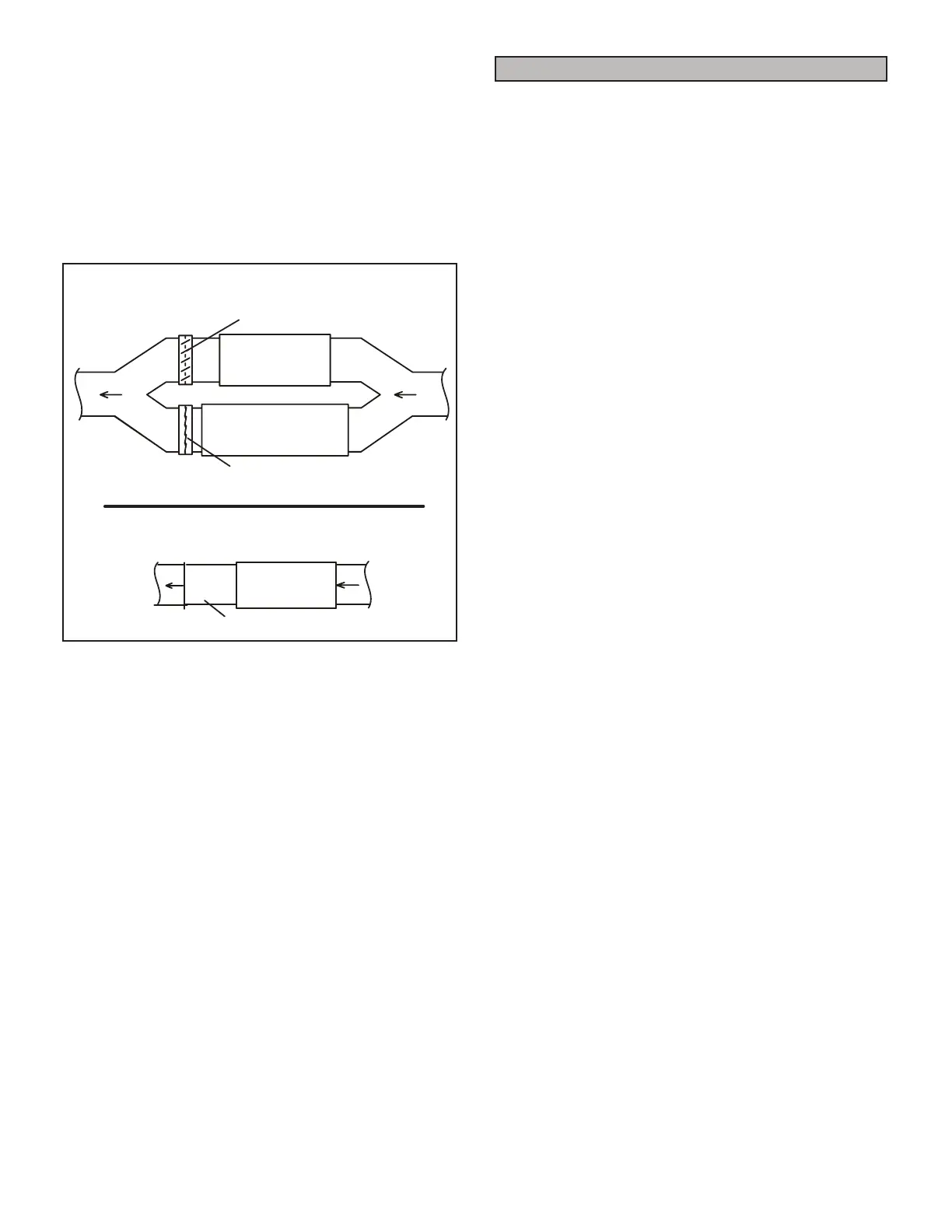

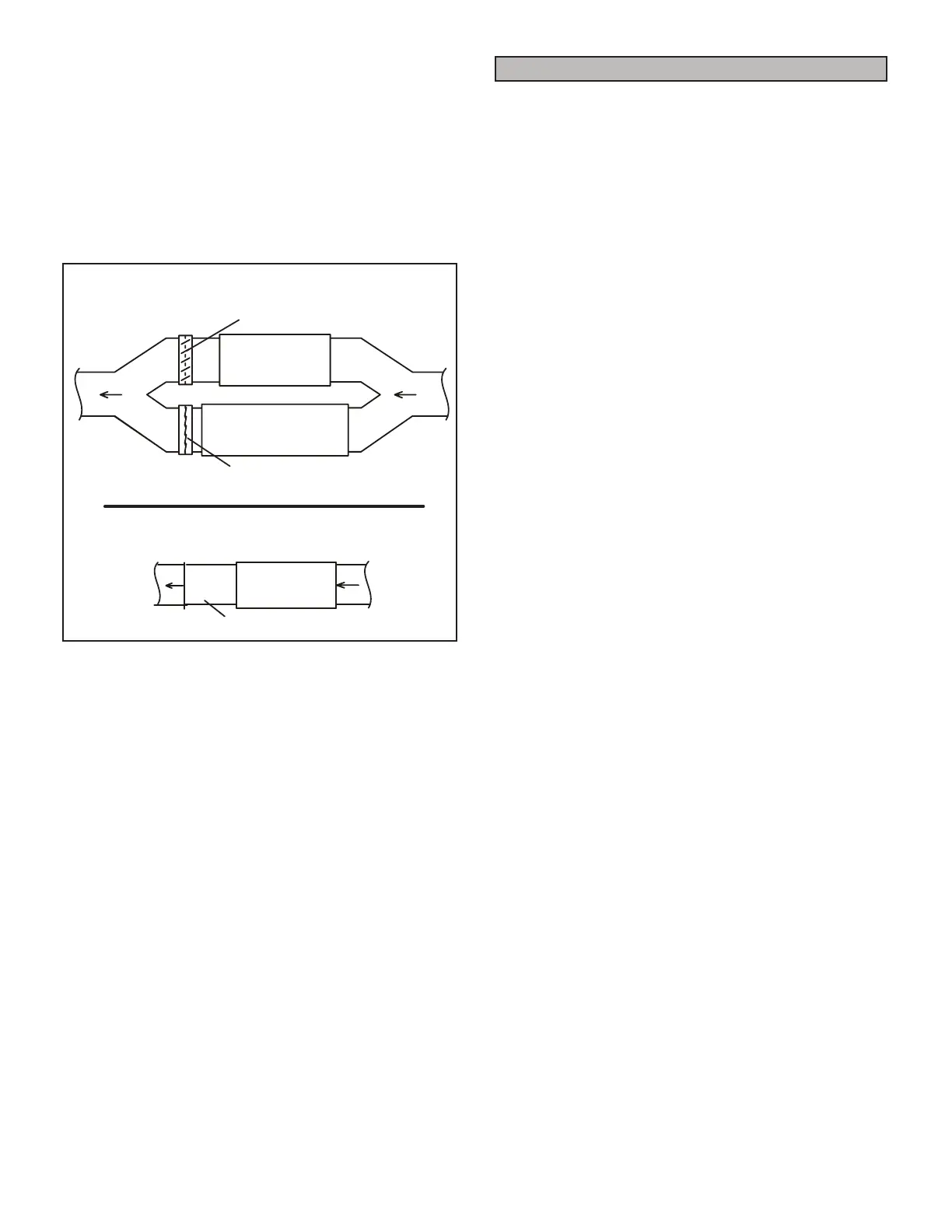

Installed in Combination with a Cooling Coil

When this furnace is used with cooling units, it shall be

installed in parallel with, or on the upstream side of, cool-

ing units to avoid condensation in the heating compart-

ment. See FIGURE 1. With a parallel ow arrangement,

a damper (or other means to control the ow of air) must

adequately prevent chilled air from entering the furnace. If

the damper is manually operated, it must be equipped to

prevent operation of either the heating or the cooling unit,

unless it is in the full HEAT or COOL setting. See FIGURE

1.

Gas Unit

Heating Unit Installed Upstream of Cooling Unit

Gas Unit

Dampers

(open during heating operation only)

Dampers

(open during cooling operation only)

Heating Unit Installed Parallell to Air Handler Unit

Air Handler Unit

Evaporator

FIGURE 1

When installed, this furnace must be electrically grounded

according to local codes. In addition, in the United States,

installation must conform with the current National Elec-

tric Code, ANSI/NFPA No. 70. The National Electric Code

(ANSI/NFPA No. 70) is available from the following ad-

dress:

National Fire Protection Association

1 Battery March Park

Quincy, MA 02269

NOTE - This furnace is designed for a minimum continu-

ous return air temperature of 60°F (16°C) or an intermittent

operation down to 55°F (13°C) dry bulb for cases where a

night setback thermostat is used. Return air temperature

must not exceed 85°F (29°C) dry bulb.

The EL180UHNE furnace may be installed in alcoves,

closets, attics, basements, garages, crawl spaces and

utility rooms in the upow or horizontal position.

This furnace design has not been CSA International

certied for installation in mobile homes, recreational

vehicles, or outdoors.

Use of Furnace as Construction Heater

Lennox does not recommend the use of EL180UHNE

units as a construction heater during any phase of con-

struction. Very low return air temperatures, harmful vapors

and operation of the unit with clogged or misplaced lters

will damage the unit.

EL180UHNE units may be used for heating of buildings or

structures under construction, if the following conditions

are met:

• The vent system must be permanently installed per

these installation instructions.

• A room thermostat must control the furnace. The

use of xed jumpers that will provide continuous

heating is not allowed.

• The return air duct must be provided and sealed to

the furnace.

• Return air temperature range between 60°F (16°C)

and 80°F (27°C) must be maintained.

• Air lters must be installed in the system and must

be maintained during construction.

• Air lters must be replaced upon construction com-

pletion.

• The input rate and temperature rise must be set per

the furnace rating plate.

• One hundred percent (100%) outdoor air must be

provided for combustion air requirements during

construction. Temporary ducting may supply out-

door air to the furnace. Do not connect duct directly

to the furnace. Size the temporary duct following

these instructions in section for Combustion, Dilu-

tion and Ventilation Air in a conned space with air

from outside.

• The furnace heat exchanger, components, duct

system, air lters and evaporator coils must be

thoroughly cleaned following nal construction

clean-up. All furnace operating conditions (includ-

ing ignition, input rate, temperature rise and vent-

ing) must be veried according to these installation

instructions.

Loading...

Loading...