Page 58

High Pressure Switch Protection Errors

TABLE 12. Outdoor Control 7-Segment Display Alert Codes

System fault and lockout codes take precedence over system status codes (cooling, heating operating percentages or defrost/dehu-

midication). Only the latest active fault or lockout codes are displayed (if present). If no fault or lockout codes are active, then system

status codes are displayed. Alert codes are also displayed on the communicating thermostat.

Alert

Codes

Priority Alarm Description Possible Causes and Clearing Alarm

E 412 Moderate

The outdoor unit high pressure

switch has opened.

Unit pressure is above the upper limit. System is shut down. The high pressure

switch opens at 590PSIG and closes at 418PSIG. Conrm that the system is properly

charged with refrigerant. Check for clogged TXV, blockage to indoor unit blower

motor, clogged refrigerant lter. Conrm that the outdoor unit is clean. The alarm

clears after the pressure switch closes or a power reset.

For heating, indoor CFM may be set too low. For zoning system, zone CFM may be

set too low.

E 413 Critical

The high pressure switch has

opened 5 times within one hour. As

a result, the outdoor unit is locked

out.

Open high pressure switch error count reached 5 strikes. System is shut down. The

high pressure switch for HFC410A will open at 590PSIG and close at 418PSIG.

Conrm that the system is properly charged with refrigerant. Check condenser fan

motor, clogged TXV, blockage to indoor unit blower motor, stuck reversing valve or

clogged refrigerant lter. Conrm that the outdoor unit is clean. The alarm clears after

indoor power reset (24VAC power source to Outdoor Control)

Compressor Operation, Checkout and Status / Error Codes

OPERATION:

The EL23XCV uses two dierent types of compressor, depending on the specic model. The EL23XCV-024, -036 and

-048 use a 380VAC three phase variable capacity rotary compressor specically designed for unitary splits system and is

approved for use with HFC 410A refrigerant. The EL23XCV-060 unit uses a 380VAC three phase variable capacity scroll

compressor that is approved for use with HFC 410A refrigerant. The compressor, when connected to an inverter, is capa-

ble of operating in a running frequency range from 20 hertz up to a maximum of 70 hertz. (maximum hertz is dependent

on compressor size). The compressor speed is determined by thermostat demand and suction pressure when installed

with a conventional 24VAC non-communicating thermostat and by thermostat demand when installed with an S30/S40

thermostat.

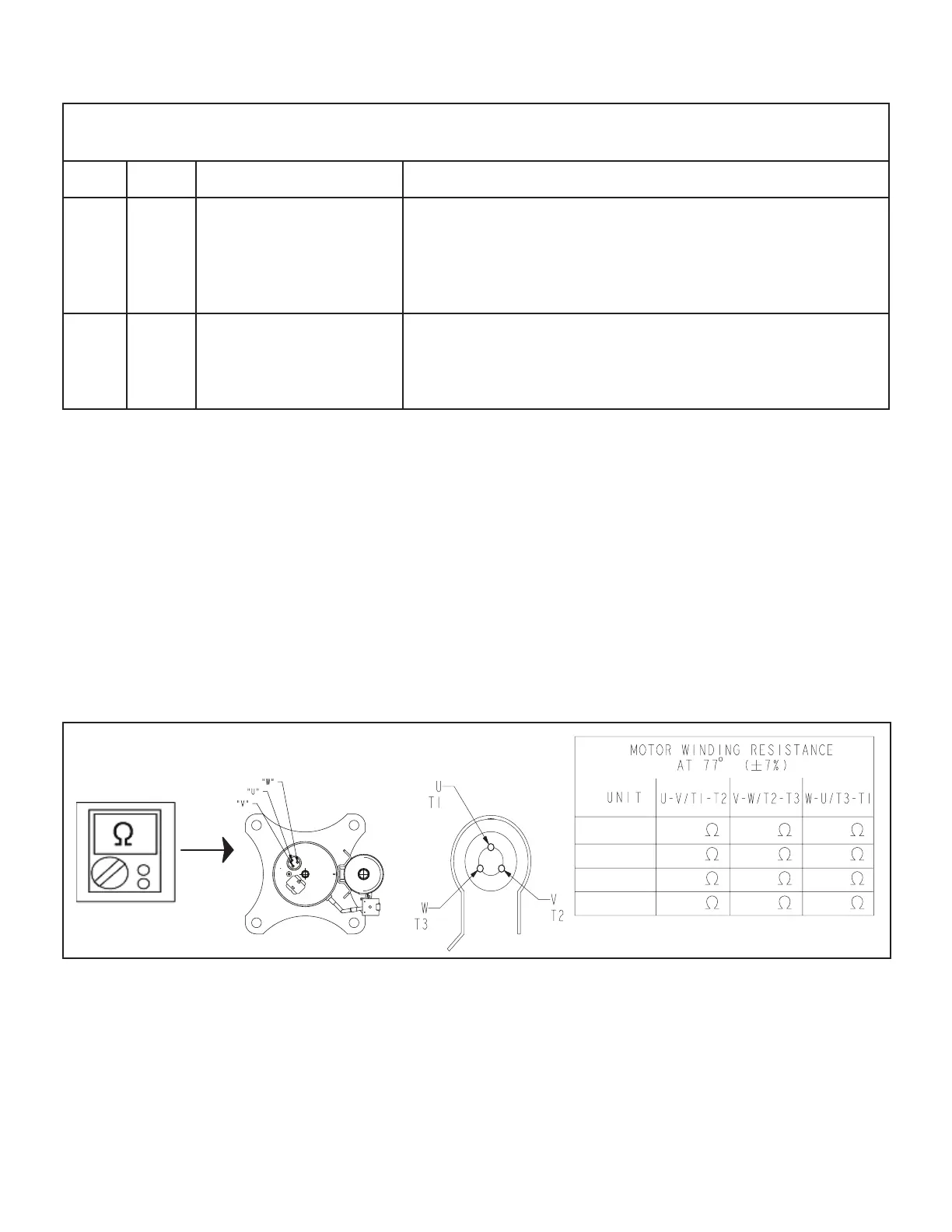

CHECKOUT:

NOTE - The compressor motor winding resistance is the nominal resistance at 77F. When measuring compressor motor

winding resistance, the primary concern is the winding resistance between the dierent sets of terminals is within 10% of

each other. The actual winding resistance is impacted by temperature, refrigerant and oil. Do not automatically condemn a

compressor because the measured resistance is slightly higher or lower than the nominal resistance. Check for shorted/

open windings and for shorts to ground during testing.

0.883

0.883

0.883

0.883

0.883

0.705

0.705

ROTARY

COMPRESSOR

SCROLL

COMPRESSOR

(EL23XCV-060 only)

EL23XCV-024

EL23XCV-036

EL23XCV-048

EL23XCV-060

0.883

0.705

0.587

0.587

0.587

FIGURE 30. Compressor Operation, Checkout and Status/Error Codes

Loading...

Loading...