Page 38

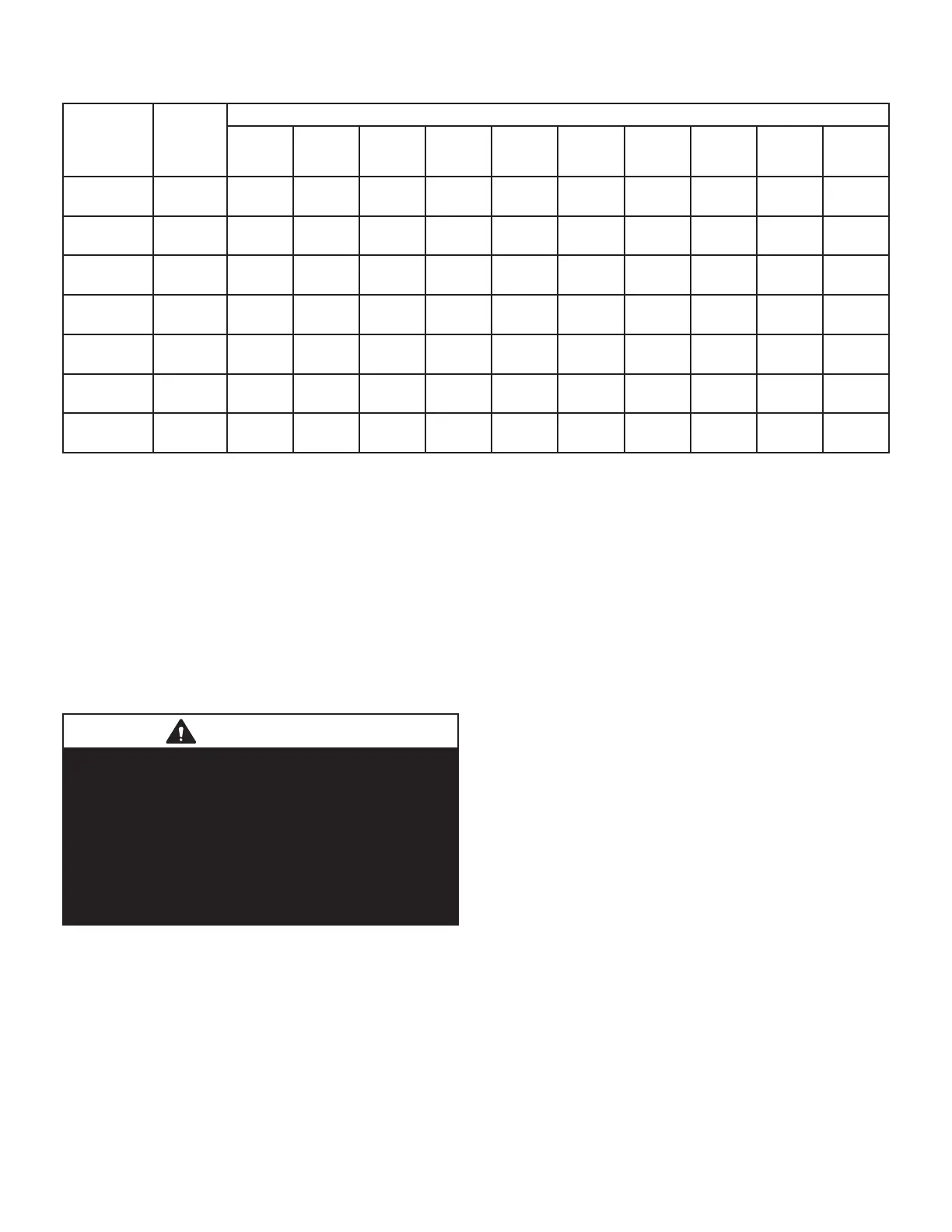

TABLE 9

Gas Pipe Capacity - ft3/hr (m3/hr)

Nominal

Iron Pipe

6L]H,QFKHV

(mm)

Internal

Diameter

inches

(mm)

Length of Pipe - feet (m)

10

(3.048)

20

(6.096)

30

(9,144)

40

(12,192)

50

(15.240)

60

(18.288)

70

(21.336)

80

(24.384)

90

(27.432)

100

(30,480)

1/2

(12.7)

.622

(17.799)

172

(4.87)

118

(3.34)

95

(2.69)

81

(2.29)

72

(2.03)

65

(1.84)

60

(1.69)

56

(1.58)

52

(1.47)

50

(1.42)

3/4

(19.05)

.824

(20.930)

360

(10.19)

247

(7.000)

199

(5.63)

170

(4.81)

151

(4.23)

137

(3.87)

126

(3.56)

117

(3.31)

110

(3.11)

104

(2.94)

1

(25.4)

1.049

(26.645)

678

(19.19)

466

(13.19)

374

(10.59)

320

(9.06)

284

(8.04)

257

(7.27)

237

(6.71)

220

(6.23)

207

(5.86)

195

(5.52)

1-1/4

(31.75)

1.380

(35.052)

1350

(38.22)

957

(27.09)

768

(22.25)

657

(18.60)

583

(16.50)

528

(14.95)

486

(13.76)

452

(12.79)

424

(12.00)

400

(11.33)

1-1/2

(38.1)

1.610

(40.894)

2090

(59.18)

1430

(40.49)

1150

(32.56)

985

(27.89)

873

(24.72)

791

(22.39)

728

(20.61)

677

(19.17)

635

(17.98)

600

(17.00)

2

(50.8)

2.067

(52.502)

4020

(113.83)

2760

(78.15)

2220

(62.86)

1900

(53.80)

1680

(47.57)

1520

(43.04)

1400

(39.64)

1300

(36.81)

1220

(34.55)

1160

(32.844)

2-1/2

(63.5)

2.469

(67.713)

6400

(181.22)

4400

(124.59)

3530

(99.95)

3020

(85.51)

2680

(75.88)

2480

(70.22)

2230

(63.14)

2080

(58.89)

1950

(55.22)

1840

(52.10)

NOTE -&DSDFLW\JLYHQLQFXELFIHHWPRIJDVSHUKRXUDQGEDVHGRQVSHFL¿FJUDYLW\JDV

Removal of the Furnace from Common Vent

In the event that an existing furnace is removed from a

venting system commonly run with separate gas applianc-

es, the venting system is likely to be too large to properly

vent the remaining attached appliances.

Conduct the following test while each appliance is oper-

ating and the other appliances (which are not operating)

remain connected to the common venting system. If the

venting system has been installed improperly, you must

correct the system as indicated in the general venting re-

quirements section.

WARNING

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each

appliance connected to the venting system being placed

into operation could result in carbon monoxide poisoning

or death.

The following steps shall be followed for each appliance

connected to the venting system being placed into

operation, while all other appliances connected to the

venting system are not in operation:

1 - Seal any unused openings in the common venting

system.

,QVSHFW WKH YHQWLQJ V\VWHP IRU SURSHU VL]H DQG

KRUL]RQWDOSLWFK'HWHUPLQHWKDWWKHUHLVQREORFNDJH

UHVWULFWLRQOHDNDJHFRUURVLRQRURWKHU GH¿FLHQFLHV

which could cause an unsafe condition.

3 - Close all building doors and windows and all

doors between the space in which the appliances

remaining connected to the common venting system

are located and other spaces of the building. Turn on

clothes dryers and any appliances not connected to

the common venting system. Turn on any exhaust

fans, such as range hoods and bathroom exhausts,

so they will operate at maximum speed. Do not

RSHUDWH D VXPPHU H[KDXVW IDQ &ORVH ¿UHSODFH

dampers.

4 - Follow the lighting instructions. Turn on the appliance

that is being inspected. Adjust the thermostat so that

the appliance operates continuously.

5 - After the main burner has operated for 5 minutes,

WHVW IRU OHDNV RI ÀXH JDVHV DW WKH GUDIW KRRG UHOLHI

RSHQLQJ8VHWKHÀDPHRIDPDWFKRUFDQGOH

6 - After determining that each appliance connected to

the common venting system is venting properly, (step

UHWXUQ DOO GRRUV ZLGRZV H[KDXVW IDQV ¿UHSODFH

dampers, and any other gas-burning appliances to

their previous mode of operation.

7 - If a venting problem is found during any of the

preceding tests, the common venting system must

EHPRGL¿HGWRFRUUHFWWKHSUREOHP

5HVL]H WKH FRPPRQ YHQWLQJ V\VWHP WR WKH PLQLPXP

YHQW SLSH VL]H GHWHUPLQHG E\ XVLQJ WKH DSSURSULDWH

tables in Appendix G. (These are in the current stan-

dards of the National Fuel Gas Code ANSI Z223.1.

Loading...

Loading...