IOM / ROOF-TOP FLEXY™ Series - Page 21

VENTILATION

BELT TENSION

On delivery, the drive belts are new and correctly tensioned. After the first 50 operating

hours check and adjust the tension. 80% of the total elongation of belts is generally

produced during the first 15 hours of operation.

Before adjusting the tension, make sure that the pulleys are correctly aligned.

To tension the belt, set the height of motor support plate by moving the plate

adjustment screws.

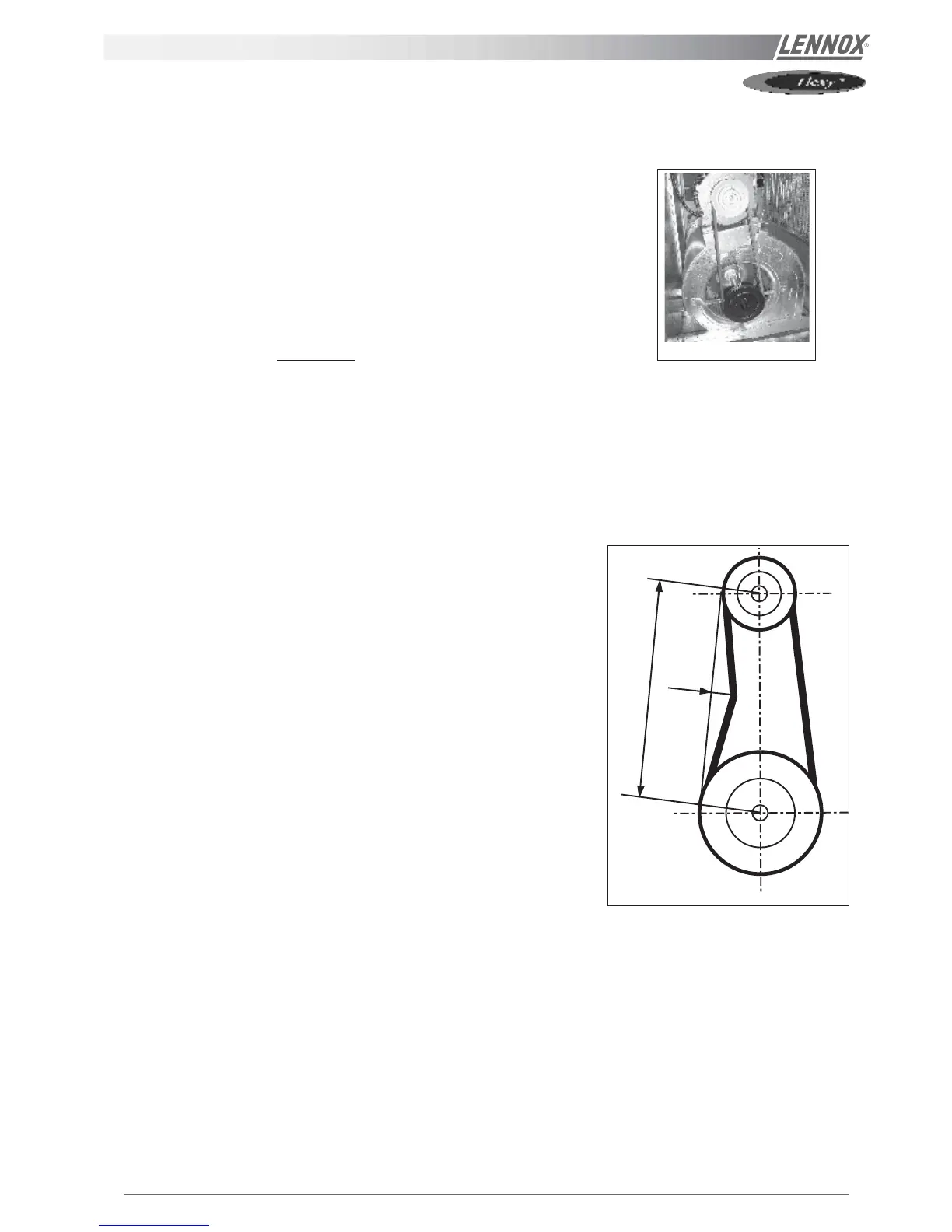

This recommended deflection is 16 mm per metre from centre to centre.

Check that according to the diagram below (figure 18), the following ratio remains

the same.

A (m)

= 20

P (mm)

The belts should always be replaced when :

- the disk is set to maximum,

- the belt rubber is worn or the wire is visible.

Replacement belts must have the same rated size as the ones they are replacing.

If a transmission system has several belts, they must all be from the same

manufacturing batch (compare serial numbers).

NOTE :

An under-tensioned belt will slip, heat and wear prematurely. On the other hand, if

a belt is over-tensioned, the pressure on the bearings will cause them to over-heat

and wear prematurely. Incorrect alignment will also cause the belts to wear

prematurely.

Loading...

Loading...