IOM / ROOF-TOP FLEXY™ Series - Page 25

AIRFLOW BALANCING

EXAMPLE

The unit used for this example is a FHK 060N with standard supply and return airflow configuration. It is also fitted with an

economiser and an electric heater type H.

It is fitted with a AT 18-18 fan which curve is shown on page xxx and a 2.2 kW motor.

- Motor rpm : 1430 rpm

- cos ϕ = 0.81

- Voltage = 400 V

- Current = 4,68A

P

mech fan

= V x I x

√√

√√

√ 3 x cos

ϕ ϕ

ϕ ϕ

ϕ x

ηη

ηη

η

mech motor

x

ηη

ηη

η

Transmission

= 400 x 4.68 x

√√

√√

√ 3 x 0.81 x 0.76 x 0.9 = 1,79 kW

The unit is also fitted with a transmission kit 1

- Fixed Fan pulley : 250 mm

- Motor adjustable pulley type "8450" opened 1 turn from fully closed or measured distance between pulley end plates is

21,8 mm: from table xxx it can be determined that the motor pulley has a diameter of 111,8 mm

rpm

FAN

= rpm

MOTOR

x D

M

/ D

F

= 1430 x 118,2 / 250 = 640 rpm

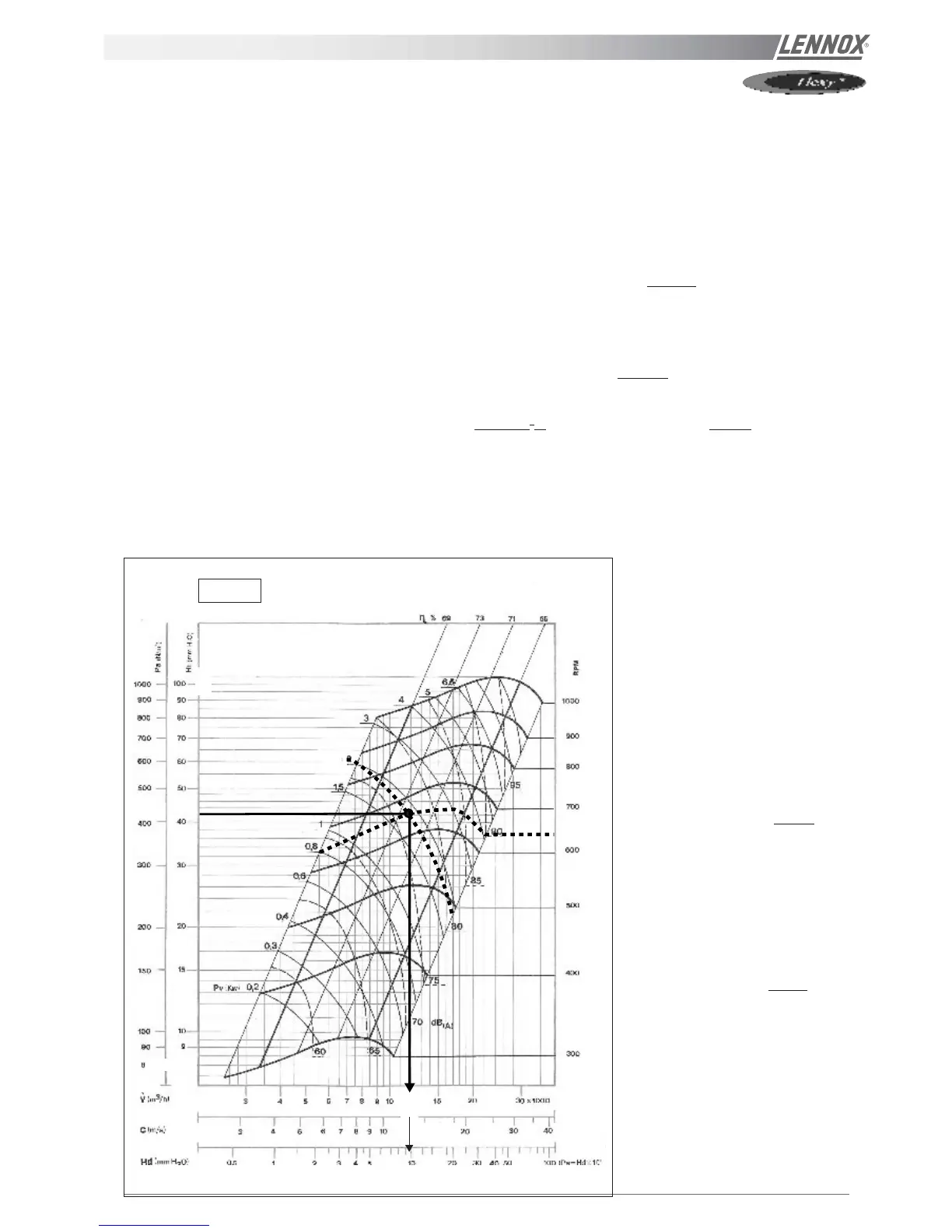

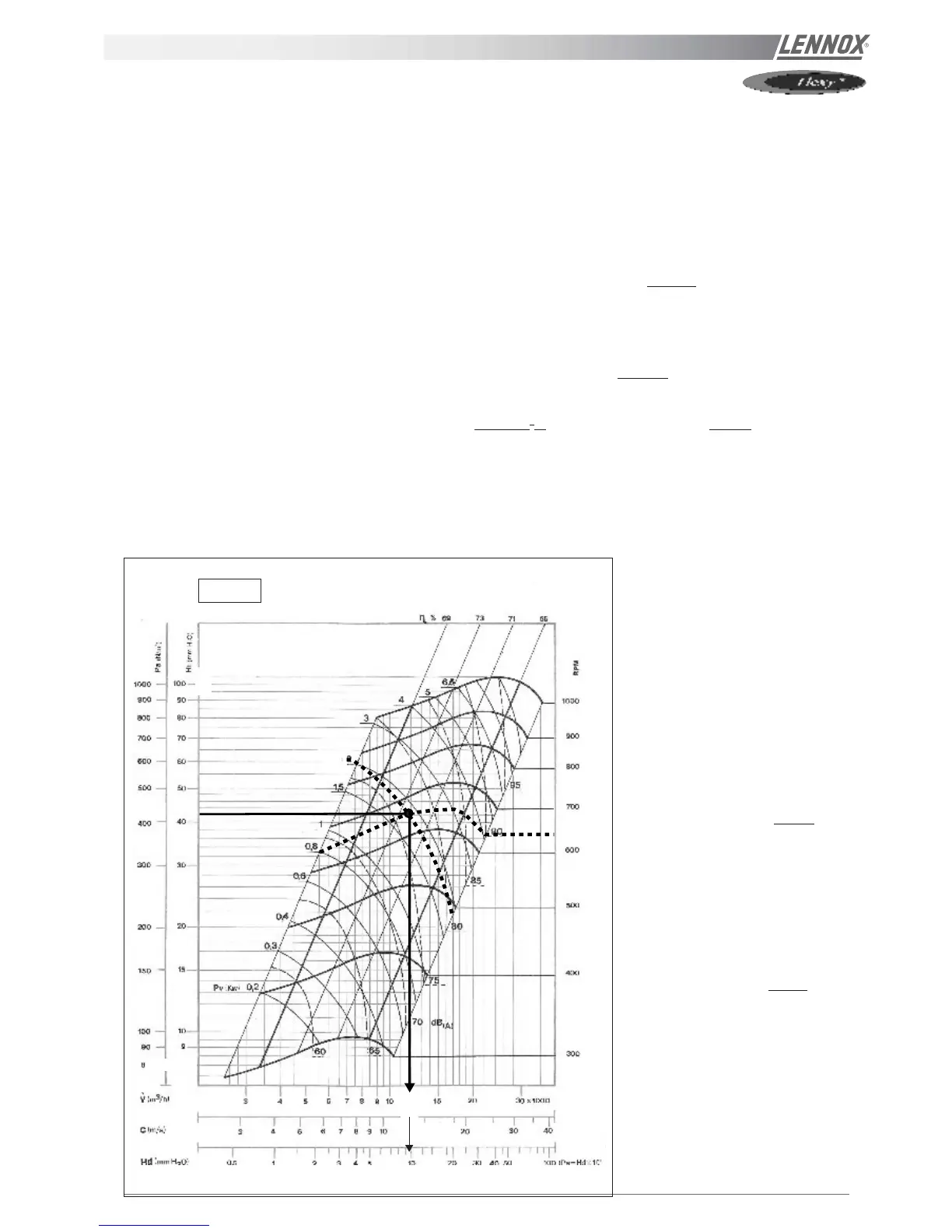

Using the fan curve below the operating point can be located.

It can be determined that the fan is providing approximately

12 000 m

3

/h with a total pressure P

TOT

= 420 Pa

640

420

12

10

1.79

Hd (mmH2O)

AT 18-18

The pressure losses in the unit are the

sum of all pressure drops across the

different parts of a unit :

- Coil and filter (measured) = 105 Pa

- Options = 6 Pa for economiser and

8 Pa for electric heater H

∆P = 105 + 6 + 8 =

119 Pa

The dynamic pressure at 1200m

3

/h is

given at the bottom of the fan curve

Pd = 100 Pa

The external static pressure available is

therefore

ESP = P

TOT

- Pd - ∆PI

NT

= 420 - 100 - 119 = 201 Pa

Figure 24

Loading...

Loading...