Page 10

gauges after shutdown to confirm that the valves are

not allowing refrigerant to flow back into the low side of

the system. Disconnect the liquid and vapor lines from

the existing outdoor unit.

2 − Remove the existing outdoor unit. Set the new R410A

unit and follow the brazing connection procedure

which begins on the previous page to make line set

connections. DO NOT install provided R410A

check/expansion valve at this time.

Make low voltage and line voltage connections to the

new outdoor unit. DO NOT turn on power to the unit

or open the outdoor unit service valves at this

time.

3 − Remove the existing refrigerant flow control orifice or

thermal expansion/check valve before continuing with

flushing procedures. The existing devices are not ap-

proved for use with R410A refrigerant and may pre-

vent proper flushing. Use a field−provided fitting to re-

connect the lines.

IMPORTANT

The line set and indoor coil must be flushed with at

least the same amount of clean refrigerant that pre-

viously charged the system. Check the charge in

the flushing cylinder before proceeding.

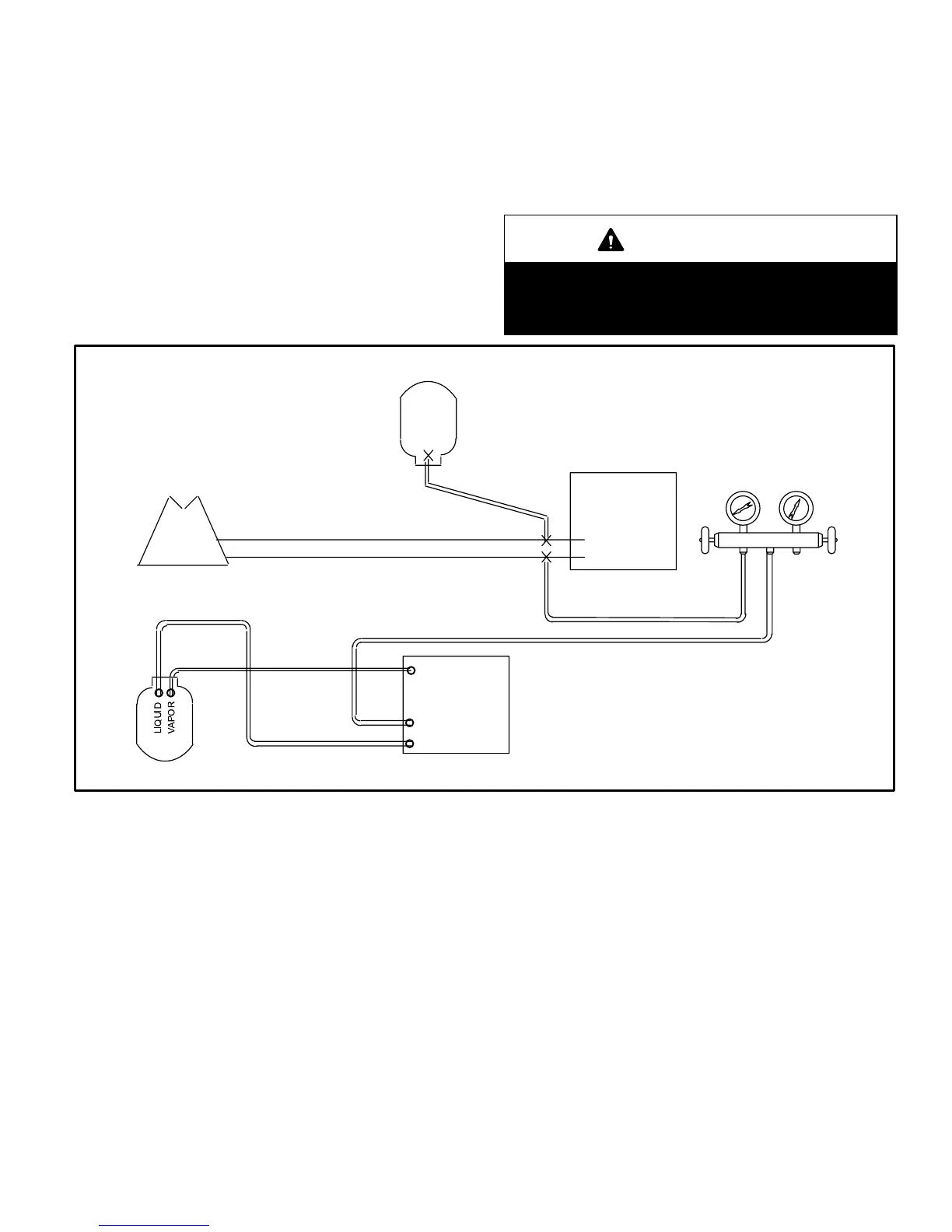

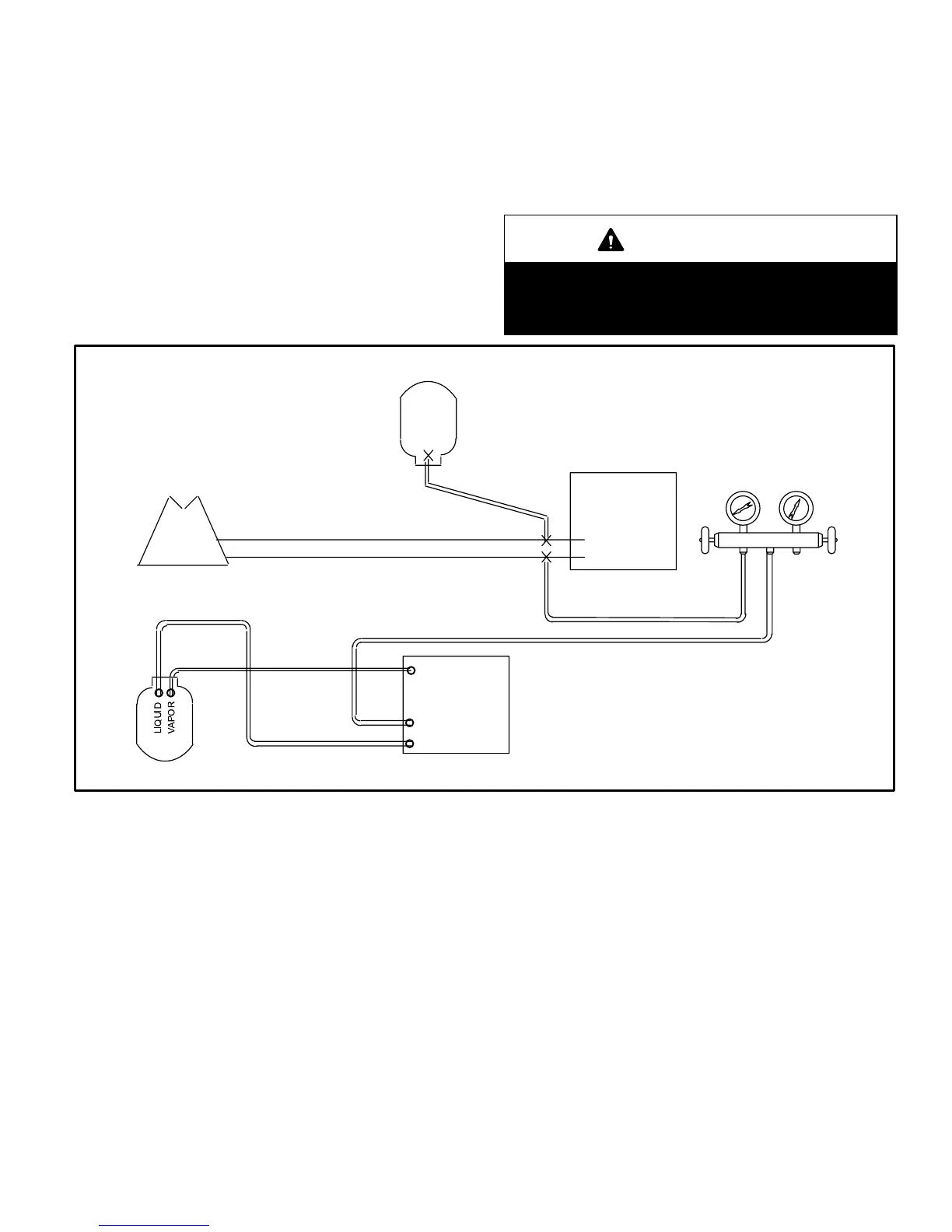

Flushing Connections

LOW

PRESSURE

HIGH

PRESSURE

VAPOR LINE

SERVICE VALVE

INDOOR COIL

HPXA12 UNIT

GAUGE MANIFOLD

RECOVERY MACHINE

INVERTED R22

CYLINDER

(Contains clean

R22 to be used for

flushing)

LIQUID LINE

SERVICE VALVE

INLET

DISCHARGE

TANK RETURN

CLOSEDOPENED

EXISTING

EXISTING VAPOR LINE

EXISTING LIQUID LINE

RECOVERY

CYLINDER

NOTE − The inverted R22 cylin-

der must contain at least the

same amount of refrigerant as

was recovered from the existing

system.

Figure 11

Loading...

Loading...