Page 5

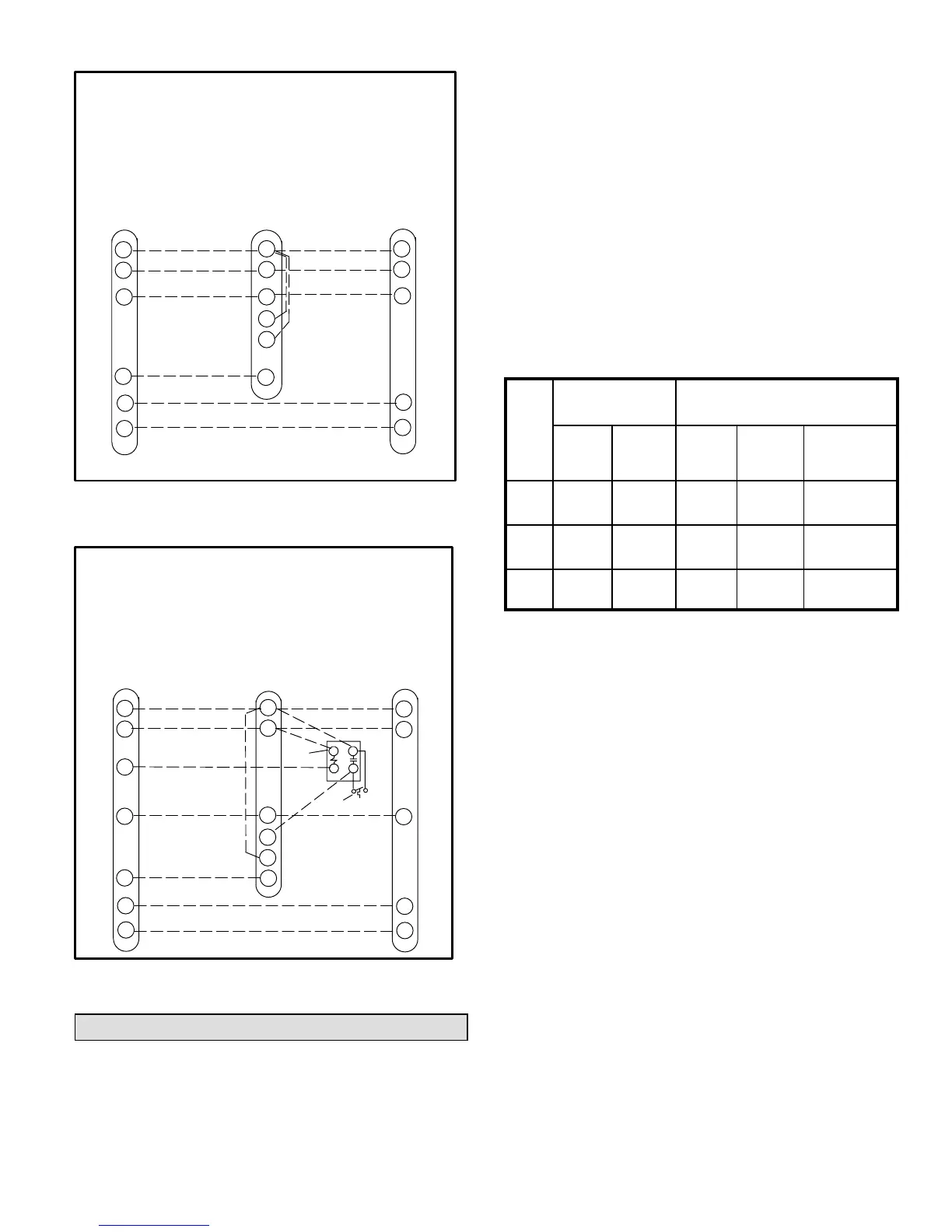

R

C

W1

Y1

O

G

R

C

W1

W2

W3

G

reversing valve

HPXA12 and Blower Unit

Thermostat Designations

(Some connections may not apply.

Refer to specific thermostat and indoor unit.)

Thermostat

Indoor

Unit

R

C

W1

Y1

O

Outdoor

Unit

power

power

common common

1st. stage aux. heat

1st. stage aux. heat

indoor blower

compressor

Figure 5

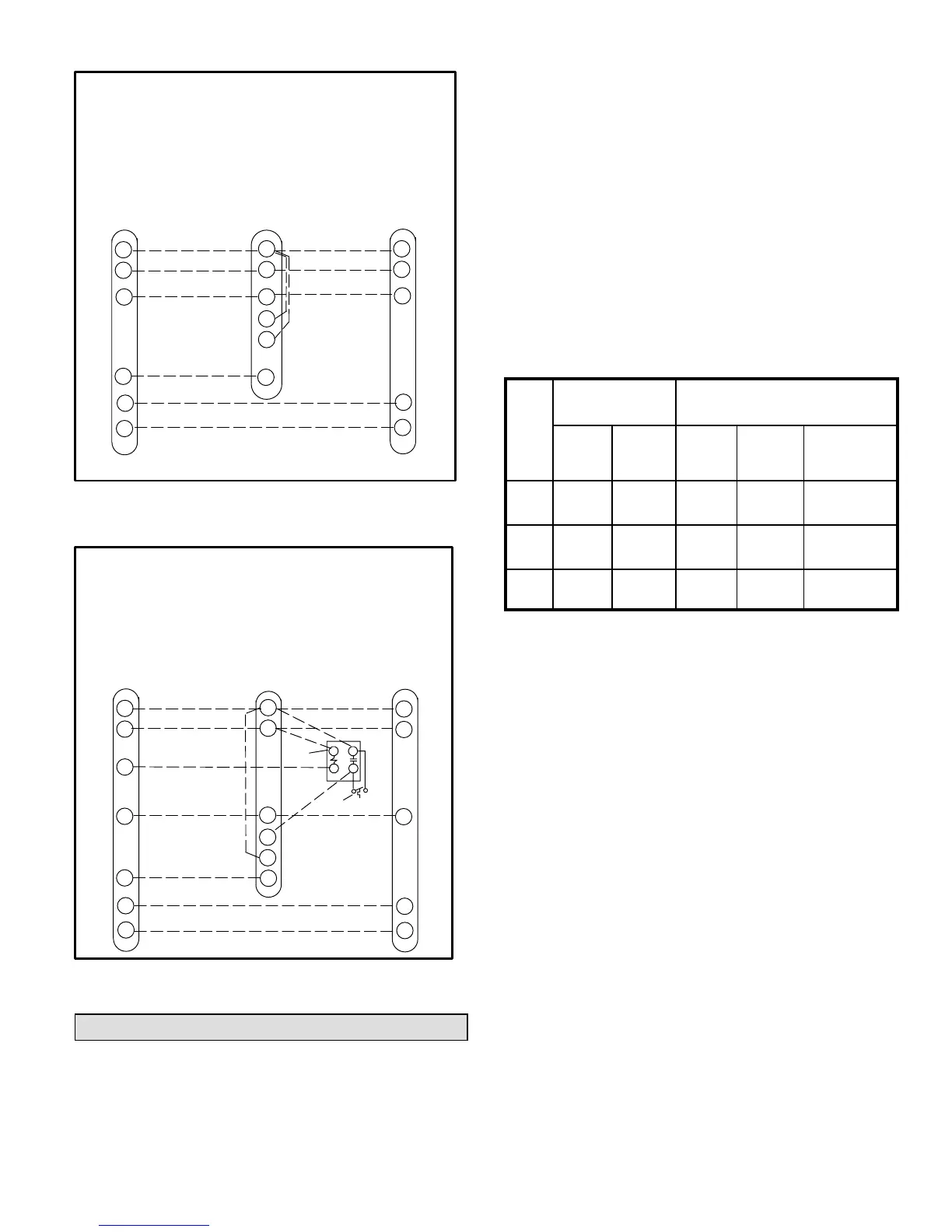

R

C

W1

Y1

O

G

R

C

W1

W2

W3

G

Outdoor Unit and Blower Unit

Thermostat Designations

(with auxiliary heat)

(Some connections may not apply.

Refer to specific thermostat and indoor unit.)

Thermostat

Indoor

Unit

Outdoor

Unit

E

R

C

W1

Y1

O

reversing valve

indoor blower

compressor

power

power

common common

1st. stage aux. heat

1st. stage aux. heat

emergency heat

em.

heat rly

outdoor t’stat

Figure 6

Refrigerant Piping

If the HPXA12 unit is being installed with a new indoor coil

and line set, the plumbing connections should be made as

outlined in this section. If an existing line set and/or indoor

coil is going to be used to complete the HPXA12 system,

refer to the following section that includes flushing proce-

dures.

Field refrigerant piping consists of liquid and vapor lines

from the outdoor unit (sweat connections) to the indoor coil

(flare or sweat connections). Use Lennox L15 (sweat, non-

flare) series line sets as shown in table 1 or use field-fabri-

cated refrigerant lines. Refer to Refrigerant Piping Guide

(Corp. 9351−L9) for proper size, type, and application of

field−fabricated lines. Valve sizes are also listed in table 1.

Plumbing Connections

HPXA12 Matched with New Indoor Coil and Line Set

If you are replacing an existing coil that is equipped

with a liquid line functioning as a metering orifice, re-

place the liquid line prior to installing the HPXA12 unit.

See table 1.

Table 1

Refrigerant Line Sets

Valve Field Size

Connections

Recommended Line Set

Model

Liquid

Line

Vapor

Line

Liquid

Line

Vapor

Line

L15

Line Sets

−18

−24

−30

3/8 in.

(10 mm)

3/4 in.

(19 mm)

3/8 in.

(10 mm)

3/4 in.

(19 mm)

L15−41

15 ft. − 50 ft.

(4.6 m − 15 m)

−36

−42

−48

3/8 in.

(10 mm)

7/8 in.

(22 mm)

3/8 in.

(10 mm)

7/8 in.

(22 mm)

L15−65

15 ft. − 50 ft.

(4.6 m − 15 m)

−60

3/8 in.

(10 mm)

1−1/8 in.

(29 mm)

3/8 in.

(10 mm)

1−1/8 in.

(29 mm)

Field

Fabricated

NOTE − Units are designed for line sets of up to fifty feet

(15m).

Installing Refrigerant Line

During the installation of any heat pump or a/c system, it is

important to properly isolate the refrigerant lines to prevent

unnecessary vibration. Line set contact with the structure

(wall, ceiling or floor) causes some objectionable noise

when vibration is translated into sound. As a result, more

energy or vibration can be expected. Closer attention to

line set isolation must be observed.

Following are some points to consider when placing and

installing a high−efficiency outdoor unit:

1- Placement − Be aware some localities are adopting

sound ordinances based on how noisy the unit is from

the adjacent property not at the original installation.

Install the unit as far as possible from the property line.

When possible, do not install the unit directly outside a

window. Glass has a very high level of sound transmis-

sion.

2- Line Set Isolation − The following illustrations demon-

strate procedures which ensure proper refrigerant line

set isolation. Figure 7 shows how to install line sets on

vertical runs. Figure 8 shows how to install line sets on

horizontal runs. Figure 9 shows how to make a transition

from horizontal to vertical. Finally, figure 10 shows how

to place the outdoor unit and line set.

Loading...

Loading...