Page 15

6 − Set the thermostat for a cooling demand, turn on power

to indoor blower unit and close the outdoor unit discon-

nect to start the unit.

7 − Recheck voltage while the unit is running. Power must

be within range shown on the nameplate.

Charging

This system is charged with R410A refrigerant which oper-

ates at much higher pressures than R22. The recom-

mended check expansion valve is approved for use with

R410A. Do not replace it with a valve that is designed to be

used with R22. This unit is NOT approved for use with coils

that include metering orifices or capillary tubes.

Processing Procedure

The unit is factory−charged with the amount of R410A re-

frigerant indicated on the unit rating plate. This charge is

based on a matching indoor coil and outdoor coil with a 15

foot (4.6 m) line set. For varying lengths of line set, refer to

table 2 for refrigerant charge adjustment. A blank space is

provided on the unit rating plate to list the actual field

charge.

Table 4

Liquid Line Set

Diameter

Oz. per 5 ft. (grams per 1.5 m) adjust

from 15 ft. (4.6 m) line set*

3/8 in.

(10 mm)

3 ounces per 5 feet

(85 g per 1.5 m)

*If line length is greater than 15 ft. (4.6 m), add this amount.

If line length is less than 15 ft. (4.6 m), subtract this amount.

IMPORTANT

Mineral oils are not compatible with R410A. If oil

must be added, it must be a polyol ester oil.

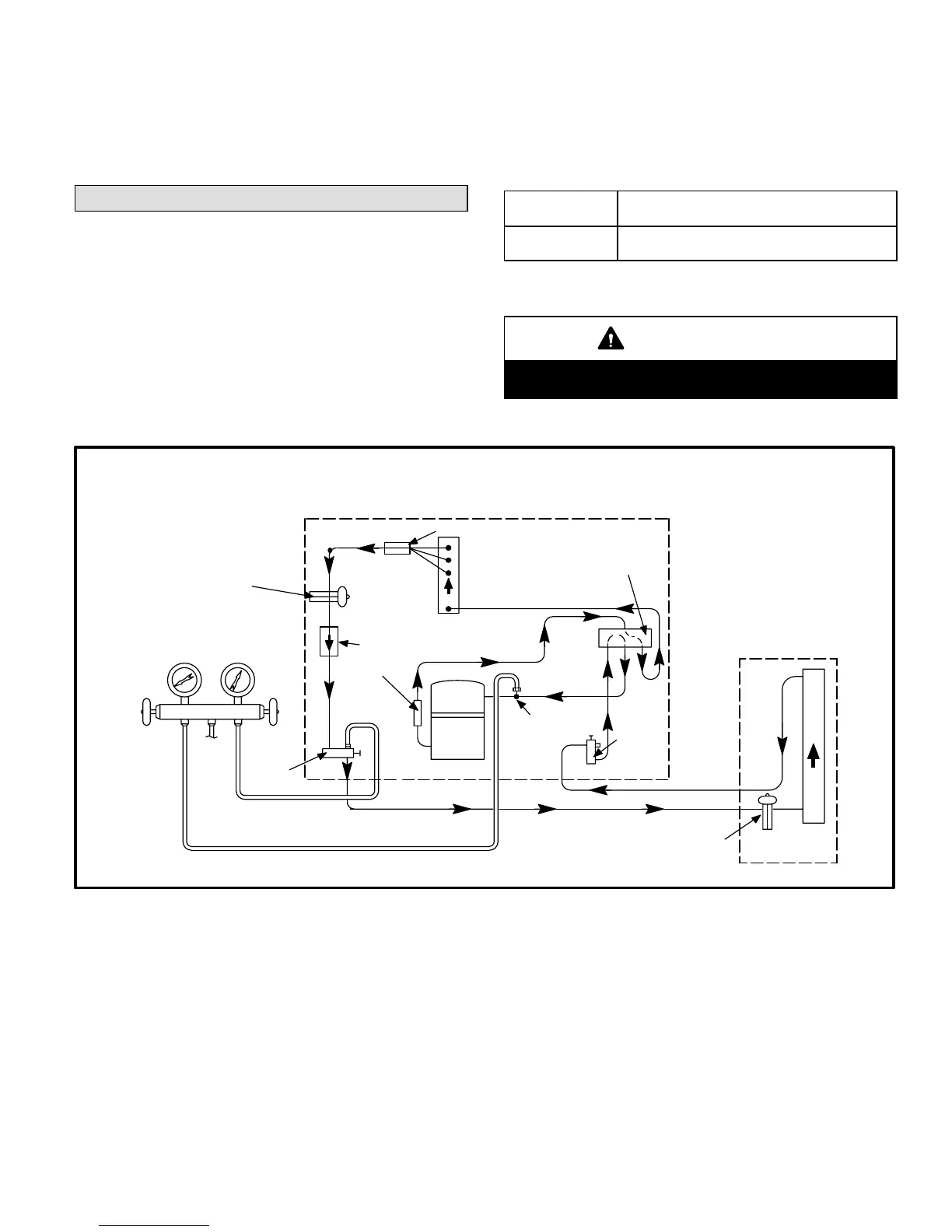

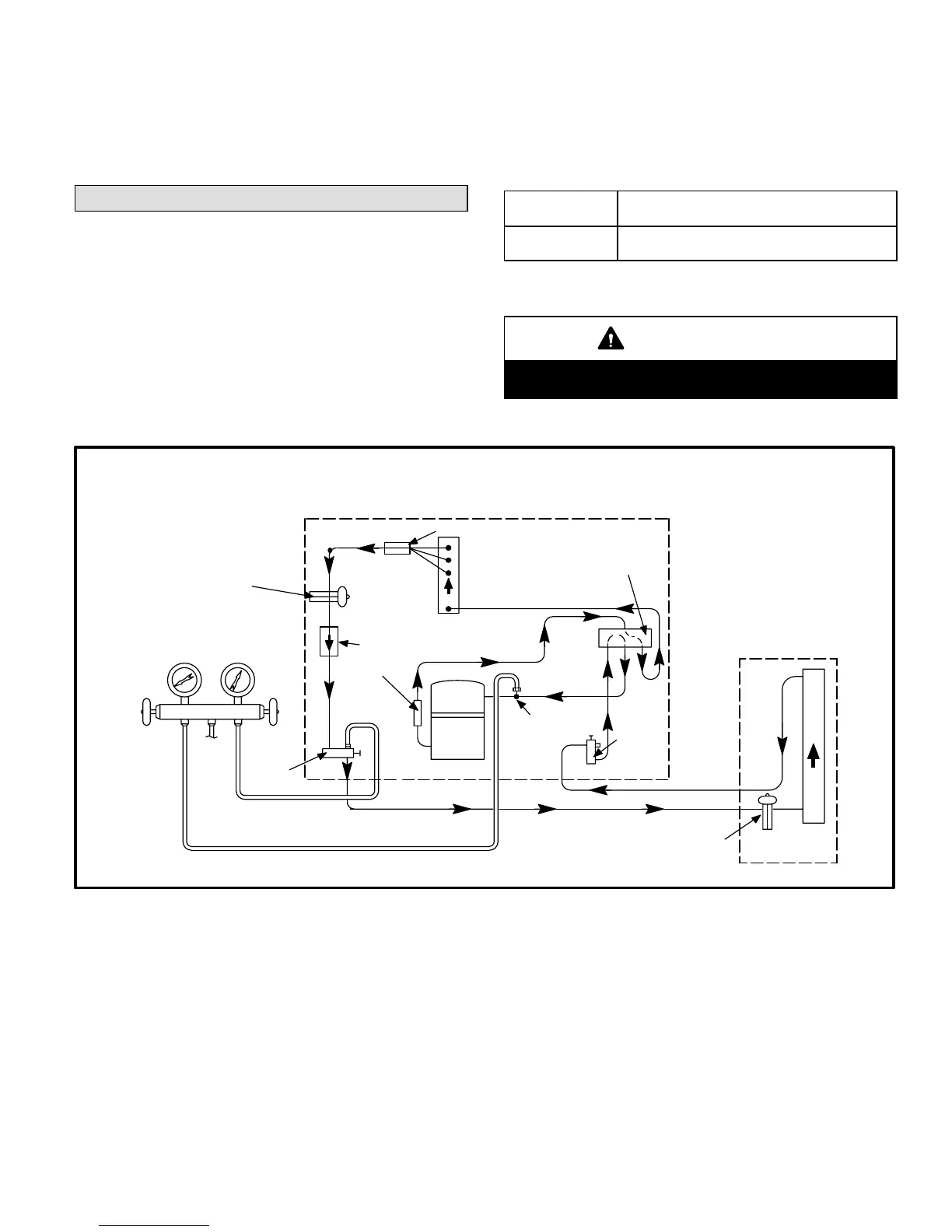

HPXA12 COOLING CYCLE

(Showing Gauge Manifold Connections)

NOTE−Use gauge ports on vapor line valve and liquid valve for evacuating refrigerant lines

and indoor coil. Use vapor gauge port to measure vapor pressure during charging.

OUTDOOR

COIL

EXPANSION/

CHECK VALVE

BIFLOW

FILTER / DRIER

TO

R410A

DRUM

LOW

PRESSURE

HIGH

PRESSURE

COMPRESSOR

REVERSING VALVE

VAPOR

LINE

VALVE

MUFFLER

NOTE − ARROWS INDICATE

DIRECTION OF REFRIGERANT FLOW

SERVICE

PORT

VAPOR

EXPANSION/CHECK

VALVE

INDOOR UNIT

OUTDOOR UNIT

LIQUID

LINE

SERVICE

PORT

GAUGE MANIFOLD

DISTRIBUTOR

INDOOR

COIL

Figure 15

Loading...

Loading...