Page 27

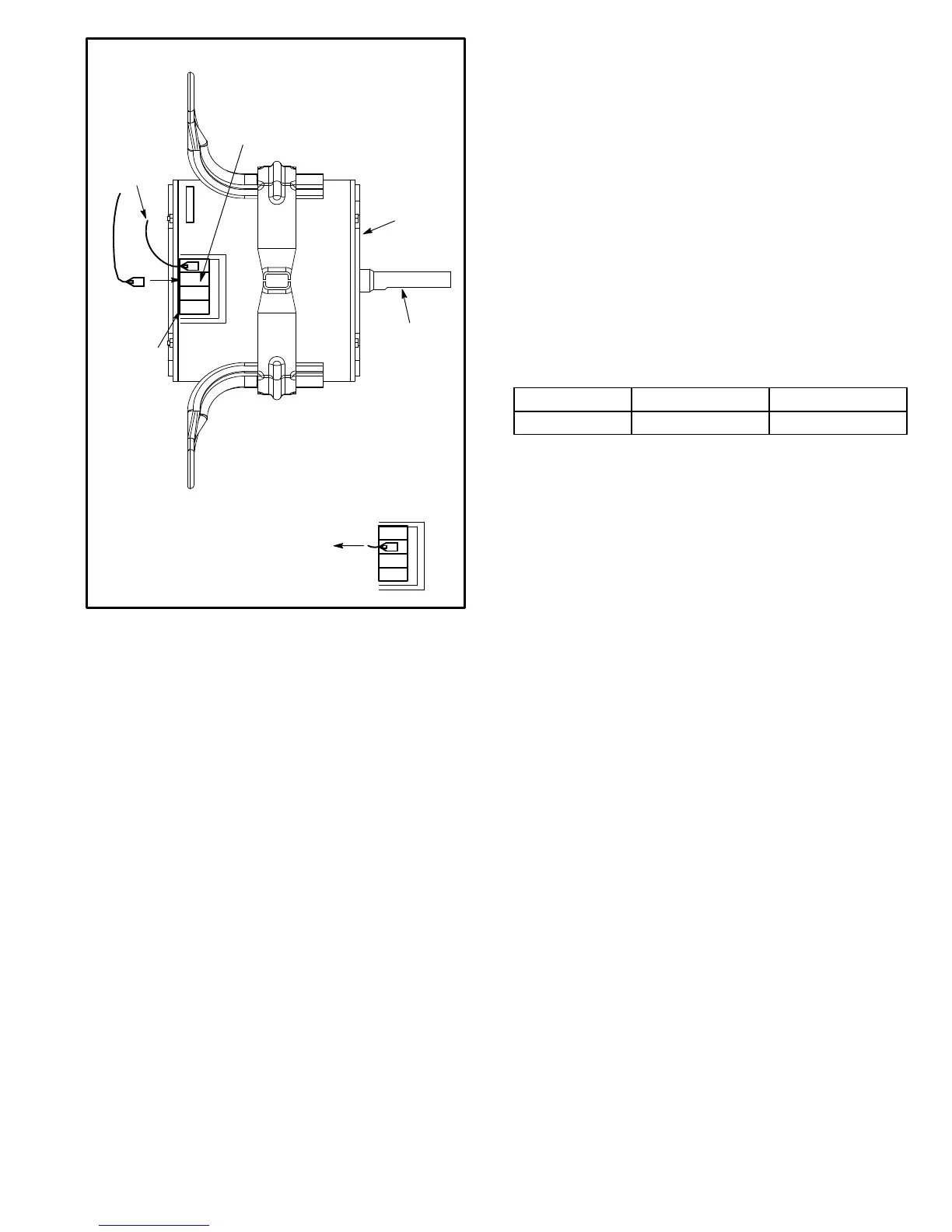

FIGURE 7

MOVE CONNECTOR TO

TERMINAL 2 FOR HIGH

STATIC APPLICATIONS

1

2

3

4

BLOWER

MOTOR

SPEED

TAPS

BLOWER

SHAFT

DIRECT DRIVE HIGH STATIC APPLICATIONS

TERMINAL 1

REMAINS AT

COMMON

1

2

3

4

460/575V UNITS:

Disconnect isolation lead before

moving speed tap wire. Tape exposed

end of isolation lead and secure away

from other components.

C−Determining Unit CFM − Belt Drive Blowers

1− The following measurements must be made with air fil-

ters in place and no cooling demand.

2− With all access panels in place, measure static pres-

sure external to unit (from supply to return).

3− Measure the indoor blower wheel RPM.

4− Referring to the blower tables starting on Page 7 use

static pressure and RPM readings to determine unit

CFM. Use air resistance table on Page 13 when instal-

ling units with any of the options or accessories listed.

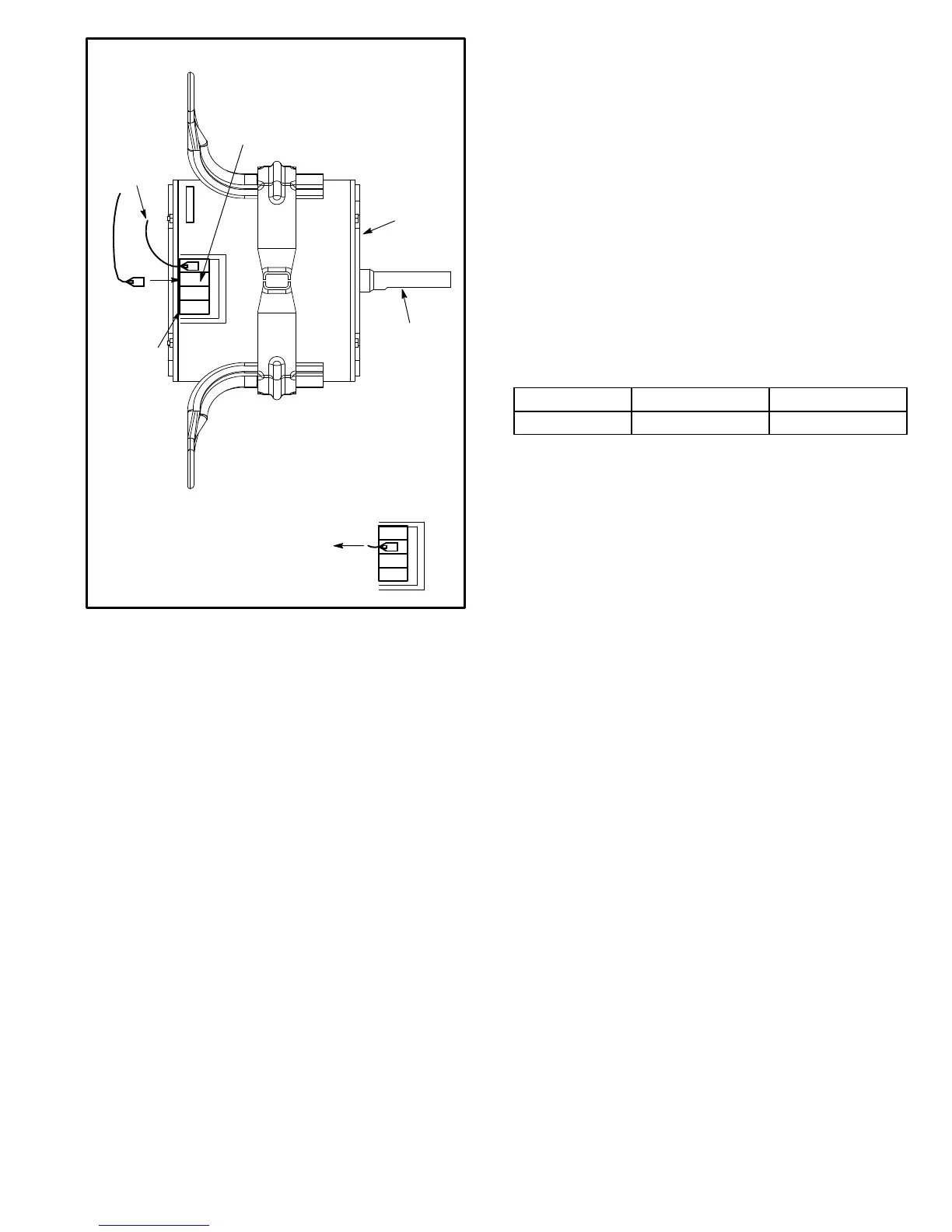

5− The blower RPM can be adjusted at the motor pulley.

Loosen Allen screw and turn adjustable pulley clock-

wise to increase CFM. Turn counterclockwise to de-

crease CFM. See figure 8. Do not exceed minimum and

maximum number of pulley turns as shown in table 2.

TABLE 2

MINIMUM AND MAXIMUM PULLEY ADJUSTMENT

Belt Min. Turns Open Max. Turns Open

A Section No minimum 5

D−Blower Belt Adjustment

Maximum life and wear can be obtained from belts only if

proper pulley alignment and belt tension are main-

tained. Tension new belts after a 24−48 hour period of

operation. This will allow belt to stretch and seat

grooves. Make sure blower and motor pulley are aligned as

shown in figure 9.

1− Loosen four bolts securing motor base to mounting

frame. See figure 8.

2− To increase belt tension −

Slide blower motor downward to tighten the belt. This

increases the distance between the blower motor and

the blower housing.

3− To loosen belt tension −

Slide blower motor upward to loosen the belt. This de-

creases the distance between the blower motor and

the blower housing.

4− Tighten four bolts securing motor base to the mounting

frame.

Loading...

Loading...