Page 33

Turning O Gas to Unit

1 - If using an electromechanical thermostat, set to the

lowest setting.

2 -

power to the appliance.

3 - Open or remove the control access panel.

4 - Move gas valve switch(es) to OFF.

Close or replace the control access panel.

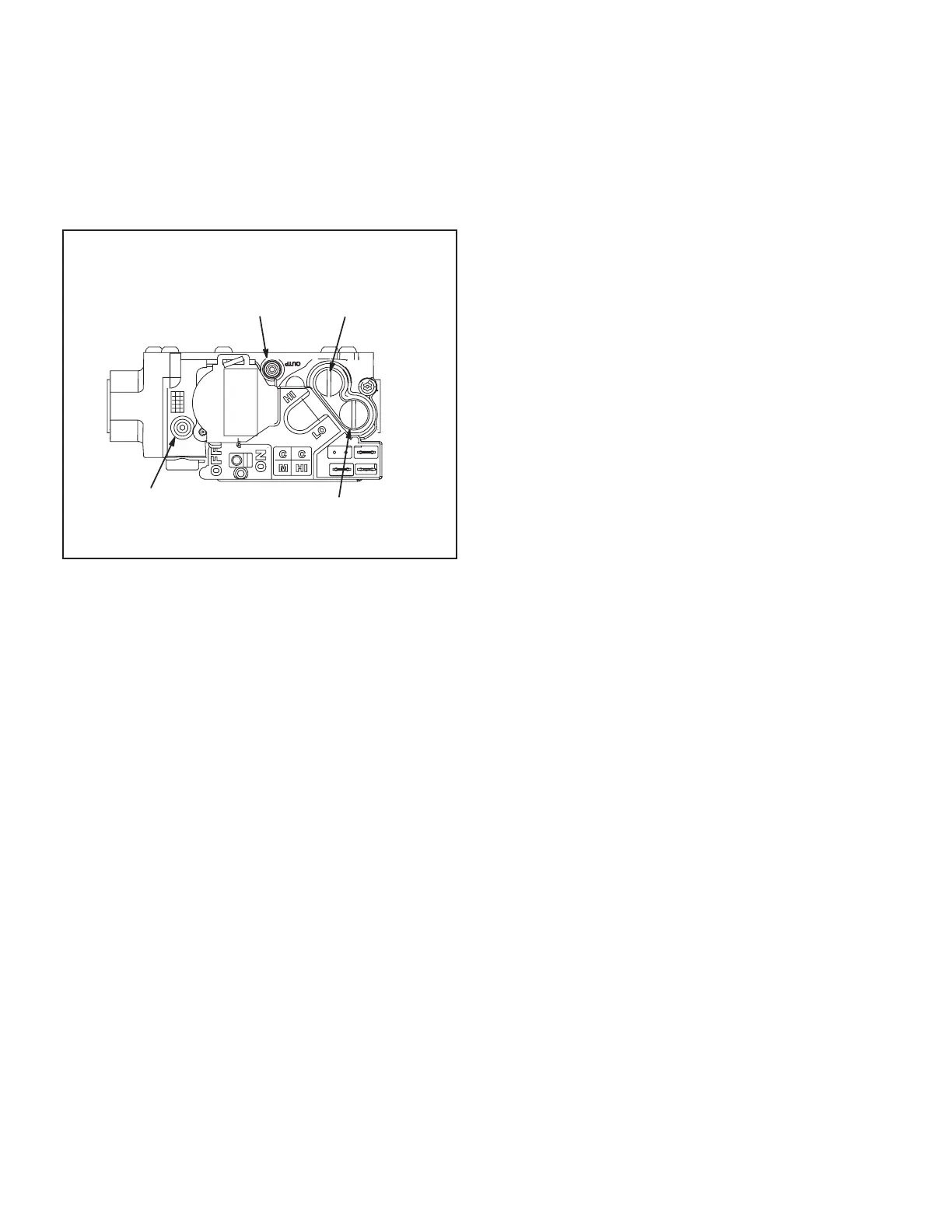

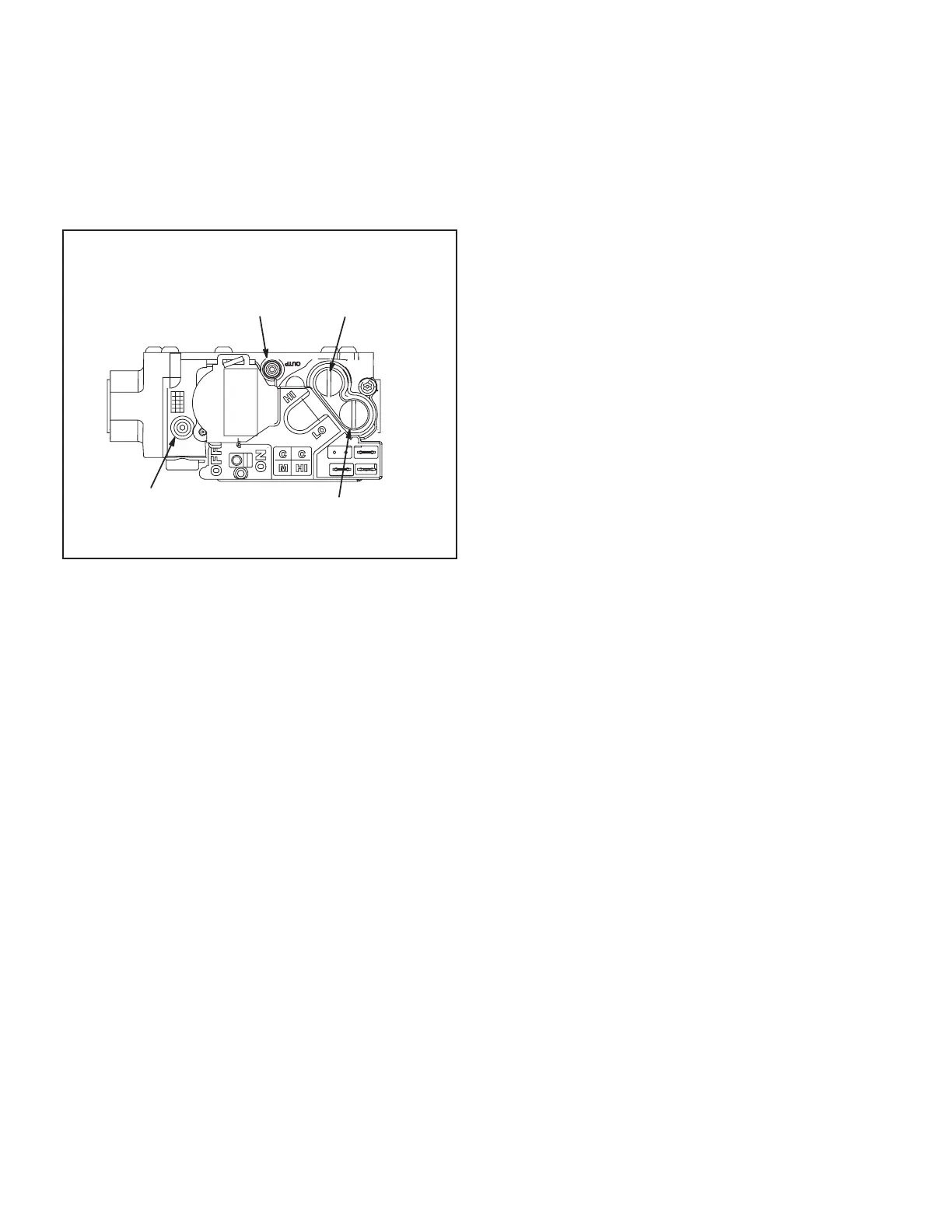

WHITE RODGERS 36J54 GAS VALVE

Two-Stage

Gas valve switch is shown in OFF position.

LOW FIRE

ADJUSTMENT

HIGH FIRE

ADJUSTMENT

INLET

PRESSURE

TAP

MANIFOLD

PRESSURE TAP

FIGURE 23

C-Cooling Start up

A-Operation

1 - Initiate full load cooling operation using the following

mobile service app menu path:

(COOL 4 on 074U units)

2 - Units contain one refrigerant circuit or stage.

3 - Unit is charged with R-410A refrigerant. See unit

rating plate for correct amount of charge.

4 - Refer to charging section method to check

refrigerant charge.

D-Safety or Emergency Shutdown

IV-CHARGING

A-Refrigerant Charge and Check - Fin/Tube Coil

WARNING-Do not exceed nameplate charge under

any condition.

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant,

reclaim the charge, evacuate the system, and add re-

quired nameplate charge.

NOTE - System charging is not recommended below 60°F

(15°C). In temperatures below 60°F (15°C) , the charge

must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

1 - Attach gauge manifolds and operate unit in cooling

mode on HIGH SPEED with economizer disabled

Make sure outdoor air dampers are closed.

Note - Use mobile service app menu path SERVICE

> TEST > COOL > COOL 3 for 036, 048 and 060U

units. Use COOL 4 for 074U units.

2 - Use a thermometer to accurately measure the

outdoor ambient temperature.

3 - Apply the outdoor temperature to tables 6 through 9

to determine normal operating pressures. Pressures

4 - Compare the normal operating pressures to

the pressures obtained from the gauges. Minor

variations in these pressures may be expected due

could mean that the system is not properly charged

or that a problem exists with some component in

the system. Correct any system problems before

proceeding.

If discharge pressure is high, remove refrigerant

from the system. If discharge pressure is low, add

refrigerant to the system.

• Add or remove charge in increments.

• Allow the system to stabilize each time refrigerant is

added or removed.

6 -

methods along with the normal operating pressures

B-Subcooling Method - Ultra High Eciency Units

1 - Attach gauge manifold to the liquid line. With the

economizer disabled, operate the unit in cooling

mode at high speed using the following mobile

service app menu path:

(COOL 4 on 074U units)

2 - Use the liquid line pressure and a PT chart to

determin the saturated liquid temperature.

3 - Measure the liquid line temperature at the condenser

outlet.

Subcooling Temperature = Liquid Saturated Tempera-

ture Minus Liquid Temperature.

4 - The subcooling temperature should be as shown

this value indicates an overcharge. A subcooling

temperature less than this value indicates an

undercharge.

Loading...

Loading...