Page 34

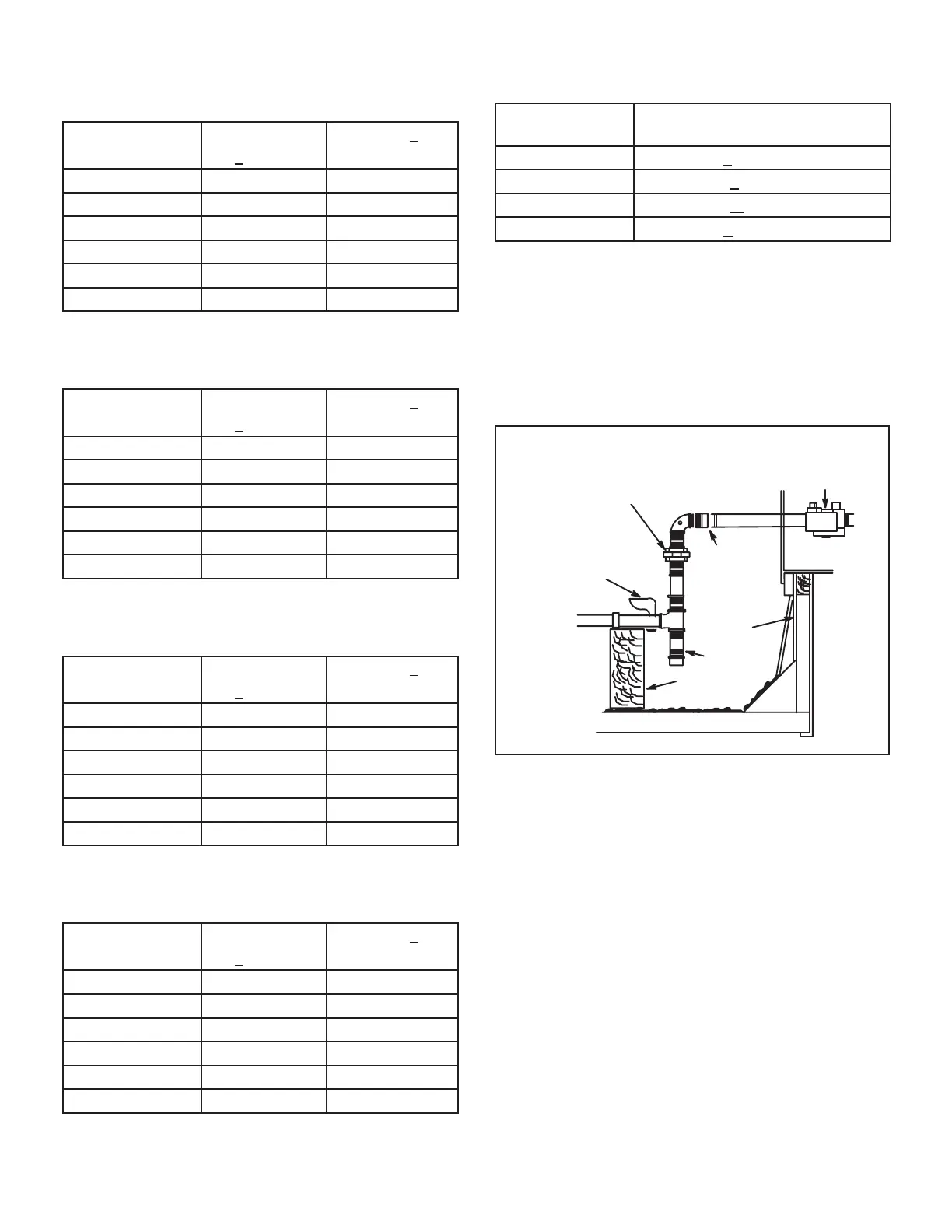

TABLE 6

LG/LC 036SU NORMAL OPERATING PRESSURES

Outdoor Coil

Entering Air Temp

Discharge

+10 psig

Suction +

psig

o

232 146

o

267 149

o

307

o

100

o

400

o

TABLE 7

LG/LC 048U NORMAL OPERATING PRESSURES

Outdoor Coil

Entering Air Temp

Discharge

+10 psig

Suction +

psig

o

142

o

289

o

332 147

o

379 149

100

o

428

o

484

TABLE 8

LG/LC 060U NORMAL OPERATING PRESSURES

Outdoor Coil

Entering Air Temp

Discharge

+10 psig

Suction +

psig

o

261

o

299 138

o

341 140

o

388 142

100

o

441 144

o

499 146

TABLE 9

LG/LC 060U NORMAL OPERATING PRESSURES

Outdoor Coil

Entering Air Temp

Discharge

+10 psig

Suction +

psig

o

268 128

o

307 134

o

137

o

399 140

100

o

142

o

144

TABLE 10

SUBCOOLING TEMPERATURE

Unit Liquid Saturated Temp. Minus

Liquid Temperature

036U

+

048U

+

060U

+

074U

+

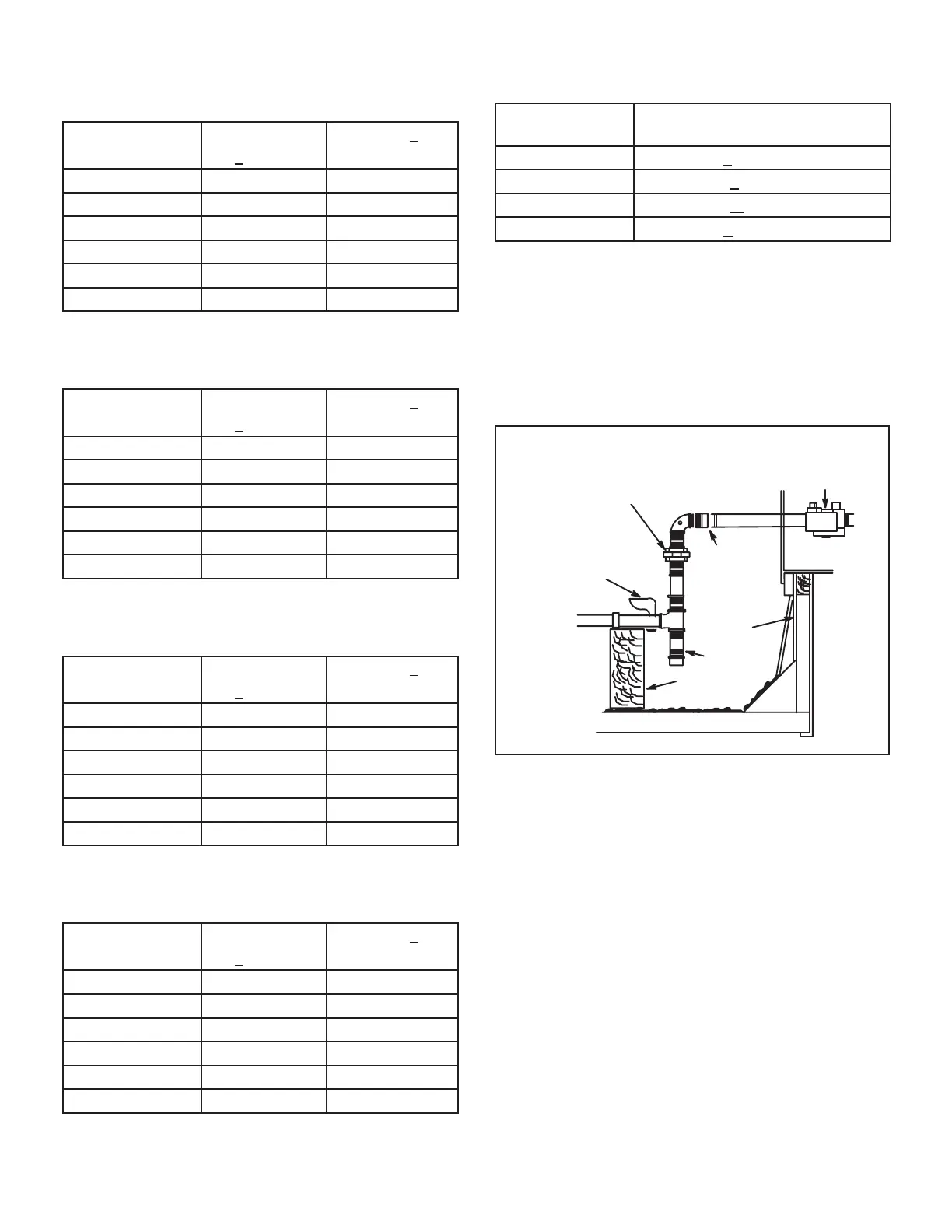

V- SYSTEMS SERVICE CHECKS

A-Heating System Service Checks

-

cation.

Before checking piping, check with gas company or au-

thorities having jurisdiction for local code requirements.

Refer to the LGM Installation instruction for more infor-

mation.

UNIT

GROUND

JOINT UNION

MANUAL MAIN

SHUT-OFF VALVE

(REFER TO LOCAL CODES)

GAS PIPING

SUPPORT

DRIP LEG

ROOF

MOUNTING

FRAME

GAS PIPING COMPONENTS

REFER TO INSTALLATION INSTRUCTIONS

VALVE

CAP HERE

TO ISOLATE

VALVE WHEN

PRESSURE

TESTING

LINE

FIGURE 24

1-Gas Piping

(124.3 Pa) drop in pressure between the gas meter and

the unit. Supply gas pipe must not be smaller than the

unit gas connection. Refer to installation instructions for

details.

2-Testing Gas Piping

NOTE- In case shutdown is required, turn o the main

manual shut-o valve and disconnect the main power to

the unit. These controls should be properly labeled by the

installer.

When pressure testing gas lines, the gas valve must be

disconnected and isolated. Gas valves can be damaged if

Loading...

Loading...