Page 36

TABLE 11

Input Rate Seconds Natuarl Seconds LP/Propane

138

34 86

24 60

6-Heat Exchanger

To Access or Remove Heat Exchanger From Unit:

1 -

2 - Remove access panel(s) and unit center mullion.

3 - Remove gas valve, manifold assembly and burners.

4 - Remove combustion air inducer. Pay careful

are removed.

Support heat exchanger (to prevent it from falling

6 - Remove screws supporting heat exchanger.

7 - To install heat exchanger, reverse procedure. Be

sure to secure all wires and check plumbing and

burner plate for airtight seal. Screws must be

7-Flame Sensing

Flame current is an electrical current which passes from

the ignition control through the sensor electrode during unit

operation. The current passes from the sensor through the

-

trode) to complete a safety circuit. The electrodes should

be located so the tips are at least 1/2” (12.7 mm) inside

NOTE-Electrodes are not eld adjustable. Any alterations

to the electrode may create a hazardous condition that

can cause property or personal injury.

1 - Disconnect power to unit.

2 - Remove lead from sensing electrode and install

sensing electrode and the sensing lead.

3 - Reconnect power and adjust thermostat for heating

demand.

4 -

Drop out signal is .09 or less.

Disconnect power to unit before disconnecting

meter. Make sure sensor wire is securely

reconnected before reconnecting power to unit.

NOTE-If the meter scale reads 0, the leads are

reversed. Disconnect power and reconnect leads

for proper polarity.

B-Cooling System Service Checks

LGM units are factory charged and require no further ad-

however, charge should be checked periodically using the

approach method. The approach method compares actual

liquid temperature with the outdoor ambient temperature.

See section IV- CHARGING.

NOTE-When unit is properly charged discharge line pres-

sures should approximate those in tables 6 through 9.

VI-MAINTENANCE

WARNING

Electric shock hazard. Can cause injury or

death. Before attempting to perform any

service or maintenance, turn the electrical

power to unit OFF at disconnect switch(es).

Unit may have multiple power supplies.

IMPORTANT

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and

dangerous operation. Verify proper operation after

servicing.

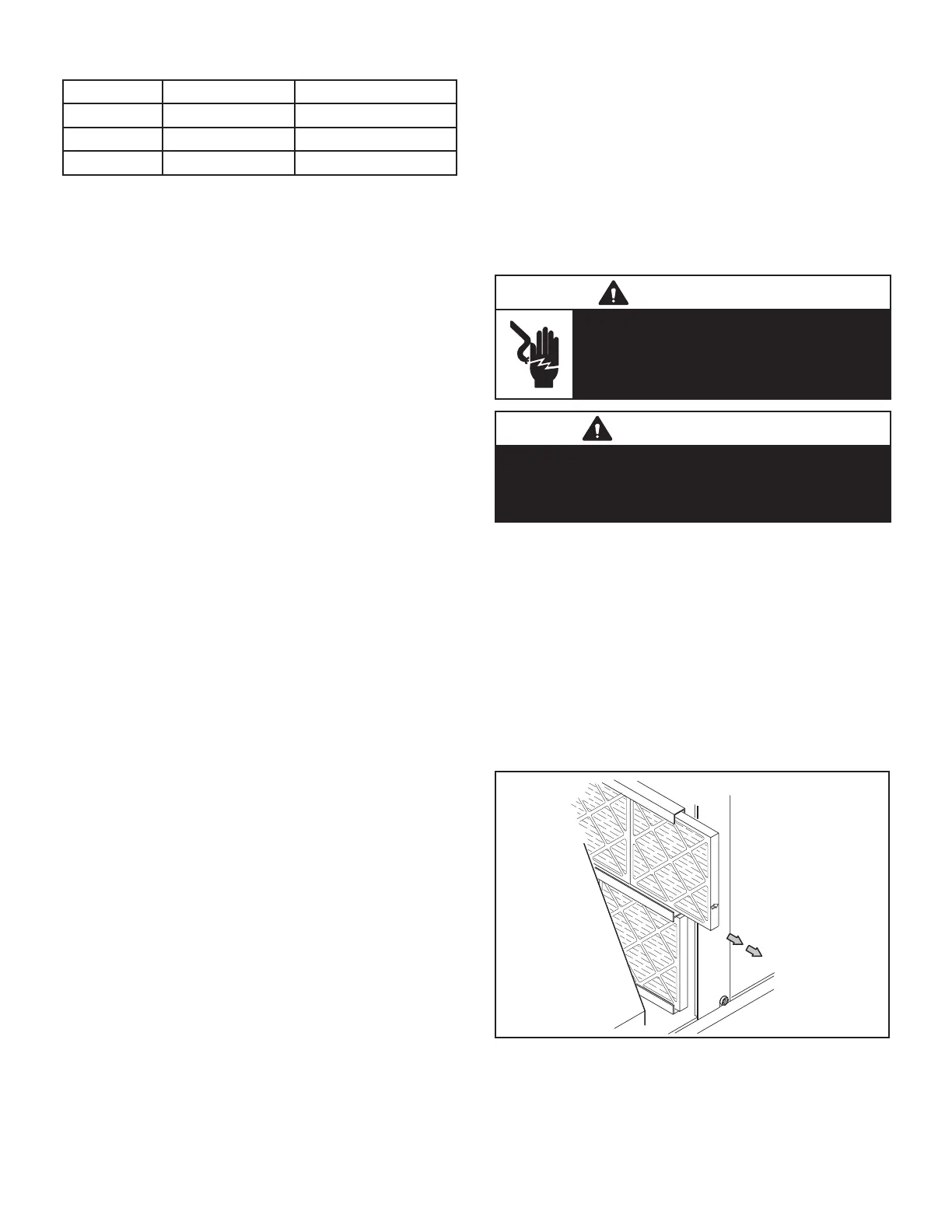

A-Filters

Refer to local codes or appropriate jurisdiction for ap-

NOTE-Filters must be U.L.C. certied or equivalent for

use in Canada.

B-Lubrication

All motors are lubricated at the factory. No further lubrica-

tion is required.

PULL TO

REMOVE

FILTERS

FIGURE 26

Loading...

Loading...