Page 35

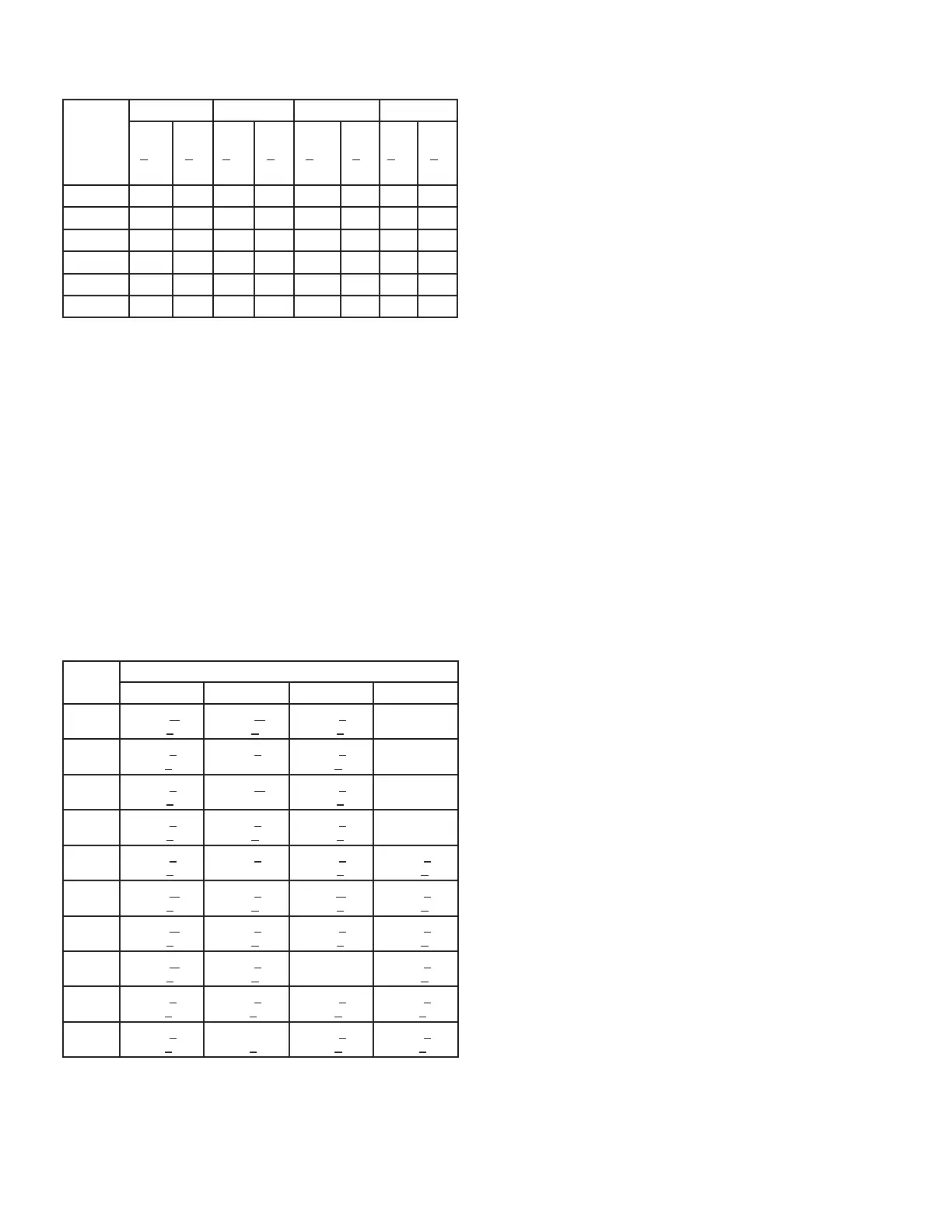

TABLE 18

300 Reheat Compressor 1 Frequency 68Hz - 581023-01

Outdoor

Coil

Entering

Air

Temp

Circuit 1 Circuit 2 Circuit 3 Circuit 4

Dis.

+10

psig

Suc.

+5

psig

Dis.

+10

psig

Suc.

+5

psig

Dis.

+10

psig

Suc.

+5

psig

Dis.

+10

psig

Suc.

+5

psig

274 121 120 114 275 120

124 122 301 123 317 128

387 124 131 135

415 442 127 137 414 141

132 130 447 142 144

525 558 133 502 145 147

-

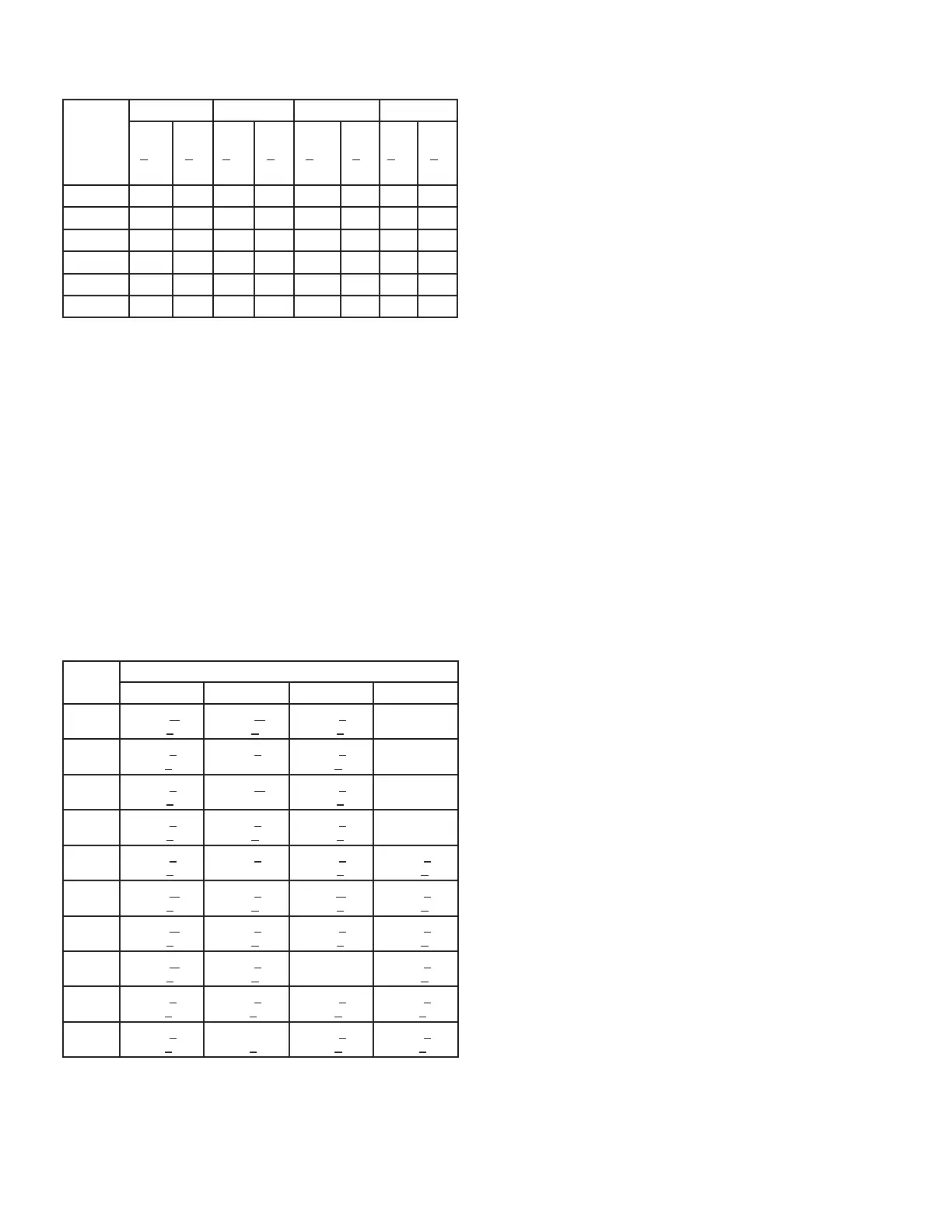

1 - Using the same thermometer, compare liquid

temperature to outdoor ambient temperature.

Approach Temperature = Liquid temperature (at con-

denser outlet) minus ambient temperature.

2 - Approach temperature should match values in table

shown indicates an undercharge. An approach

temperature less than value shown indicates an

overcharge.

3 - The approach method is not valid for grossly over or

a guide for typical operating pressures.

TABLE 19

APPROACH TEMPERATURES - FIN/TUBE COIL

Unit

Liquid Temp. Minus Ambient Temp.

1st Stage 2nd Stage 3rd Stage 4th Stage

Std.

+ 1

+0.5)

+ 1

+0.5)

+ 1

+0.5)

NA

Reheat

+1

+0.5)

+1

+1

+0.5)

NA

180

Std.

+ 1

+0.5)

+ 1

+ 1

+0.5)

NA

180

Reheat

+ 1

+0.5)

+ 1

+0.5)

+ 1

+0.5)

NA

210

Std.

+ 1

+0.5)

+ 1

+ 1

+0.5)

+ 1

+0.5)

210

Reheat

+ 1

+0.5)

+ 1

+0.5)

+ 1

+0.5)

+ 1

+0.5)

240

Std.

+ 1

+0.5)

+ 1

+0.5)

+ 1

+0.5)

+ 1

+0.5)

240

Reheat

+ 1

+0.5)

+ 1

+0.5)

+ 1

+0.5)

300

Std.

+1

+0.5)

+1

+0.5)

+1

+0.5)

+1

+0.5)

300

Reheat

+1

+0.5)

+0.5)

+1

+0.5)

+1

+0.5)

IV-STARTUP - OPERATION

Refer to startup directions and to the unit wiring diagram

when servicing. See unit nameplate for minimum circuit

ampacity and maximum fuse size.

A-Preliminary and Seasonal Checks

1 - Make sure the unit is installed in accordance with

the installation instructions and applicable codes.

2 -

installed for loose connections. Tighten as required.

Refer to unit diagram located on inside of unit

control box cover.

3 - Check to ensure that refrigerant lines are in good

condition and do not rub against the cabinet or

other refrigerant lines.

4 - Check voltage. Voltage must be within the range

listed on the nameplate. If not, consult power

company and have the voltage corrected before

starting the unit.

5 - Recheck voltage and amp draw with unit running. If

voltage is not within range listed on unit nameplate,

stop unit and consult power company. Refer to unit

nameplate for maximum rated load amps.

Inspect and adjust blower belt (see section on

Blower Compartment - Blower Belt Adjustment).

circuits

NOTE-Crankcase heaters must be energized 24 hours

before attempting to start compressor. Set thermostat so

that there is no demand to prevent compressor from cy-

cling.

Apply power to unit.

1 -

according to instructions provided with thermostat.

2 - First-stage thermostat demand will energize

indoor blower in Low Cooling CFM. Second-stage

thermostat demand will energize indoor blower

in High Cooling CFM. Both demands energize

compressor 1 (variable speed compressor).

The remaining compressors will be energized to

modulate the discharge air temperature.

3 - 156, 180-

Units contain three refrigerant circuits or systems.

210, 240, 300 -

Units contain four refrigerant circuits or systems.

4 - Each refrigerant circuit is separately charged with

R410A refrigerant. See unit rating plate for correct

amount of charge.

5 - Refer to the Refrigerant Check and Charge section

to check refrigerant charge.

Loading...

Loading...