Page 41

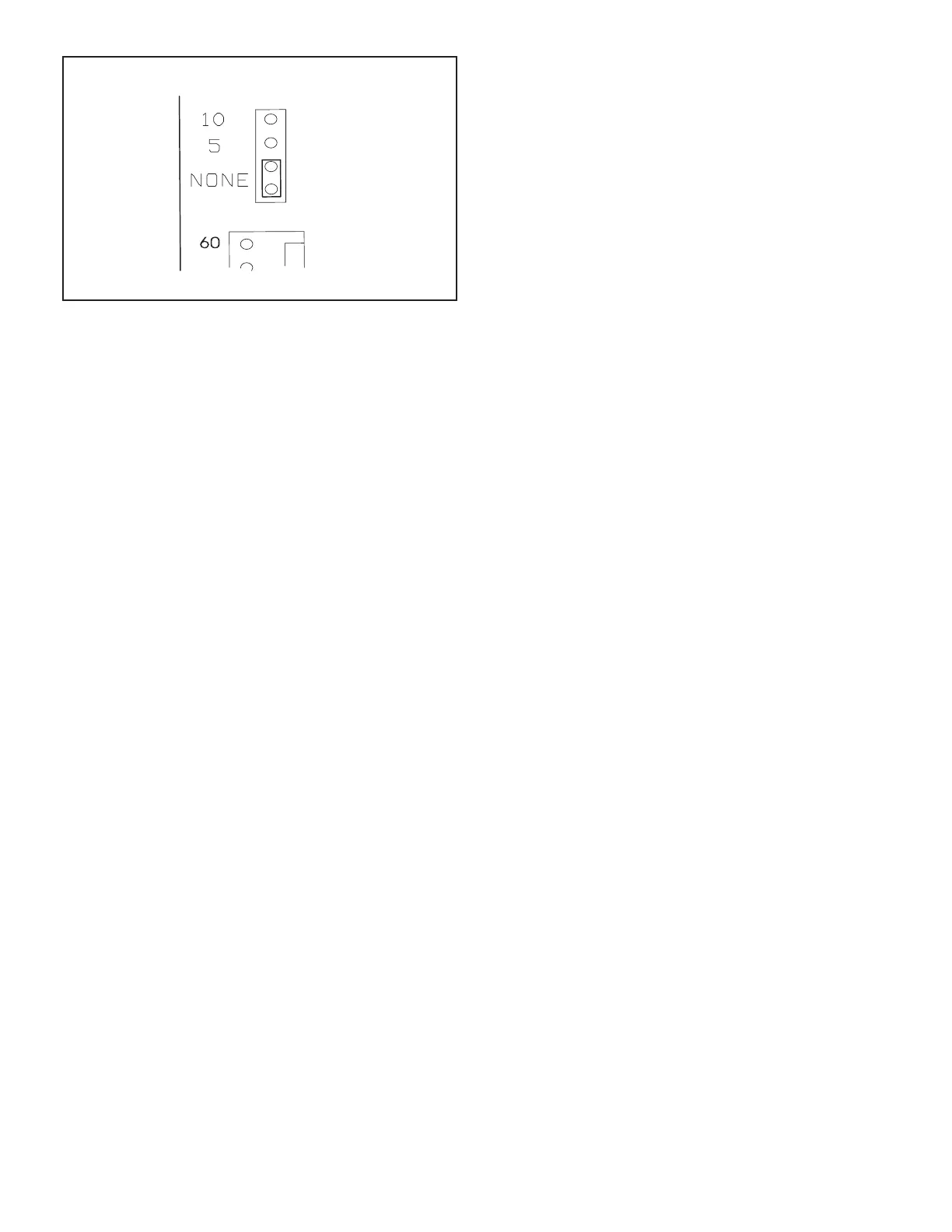

FIGURE 60

Humidier

Terminals are provided on the integrated ignition/blower

control for connection to a 120-volt humidier. The “HUM”

terminal is energized whenever the thermostat calls for

heat. See the furnace wiring diagram for specic connec-

tion information.

Electronic Air Cleaner

Terminals are provided on the integrated ignition/blower

control board for connection of a 120-volt electronic air

cleaner. The “EAC” terminal is energized whenever the

thermostat calls for heat, cooling, or continuous blower.

See furnace wiring diagram for specic connection infor-

mation.

Variable Speed Features

This furnace is equipped with a variable speed circulation

air blower motor that will deliver a constant airow within a

wide range of external static pressures. Other features of

this variable speed motor include:

Soft Start

The variable speed motor will slowly ramp up to normal

operating speed. This minimizes noise and increases

comfort by eliminating the initial blasts of air encountered

with standard motors.

Soft Stop

At the end of a cooling or heating cycle, the variable speed

motor will slowly ramp down after a short blower “o” de-

lay. If continuous blower operation has been selected, the

variable speed motor will slowly ramp down until it reach-

es the airow for that mode.

Passive and Active Dehumidication

Both the passive and active dehumidication methods de-

scribed below can be utilized on the same furnace.

Passive Dehumidication

For situations where humidity control is a problem, a

dehumidication feature has been built into the variable

speed motor. At the start of each cooling cycle, the vari-

able speed motor will run at 82% of the rated airow for

7.5 minutes. After 7.5 minutes has elapsed, the motor will

increase to 100% of the rated airow.

Active Dehumidication

To achieve additional dehumidication, clip the jumper

wire located below the DEHUM terminal on the integrat-

ed ignition/ blower control board and connect a humidity

control that opens on humidity rise to the DEHUM and R

terminals. The DEHUM terminal on the control board must

be connected to the normally closed contact of the hu-

midity control so that the board senses an open circuit on

high humidity. In this setup, the variable speed motor will

operate at a 30% reduction in the normal cooling airow

rate when there is a call for dehumidication.

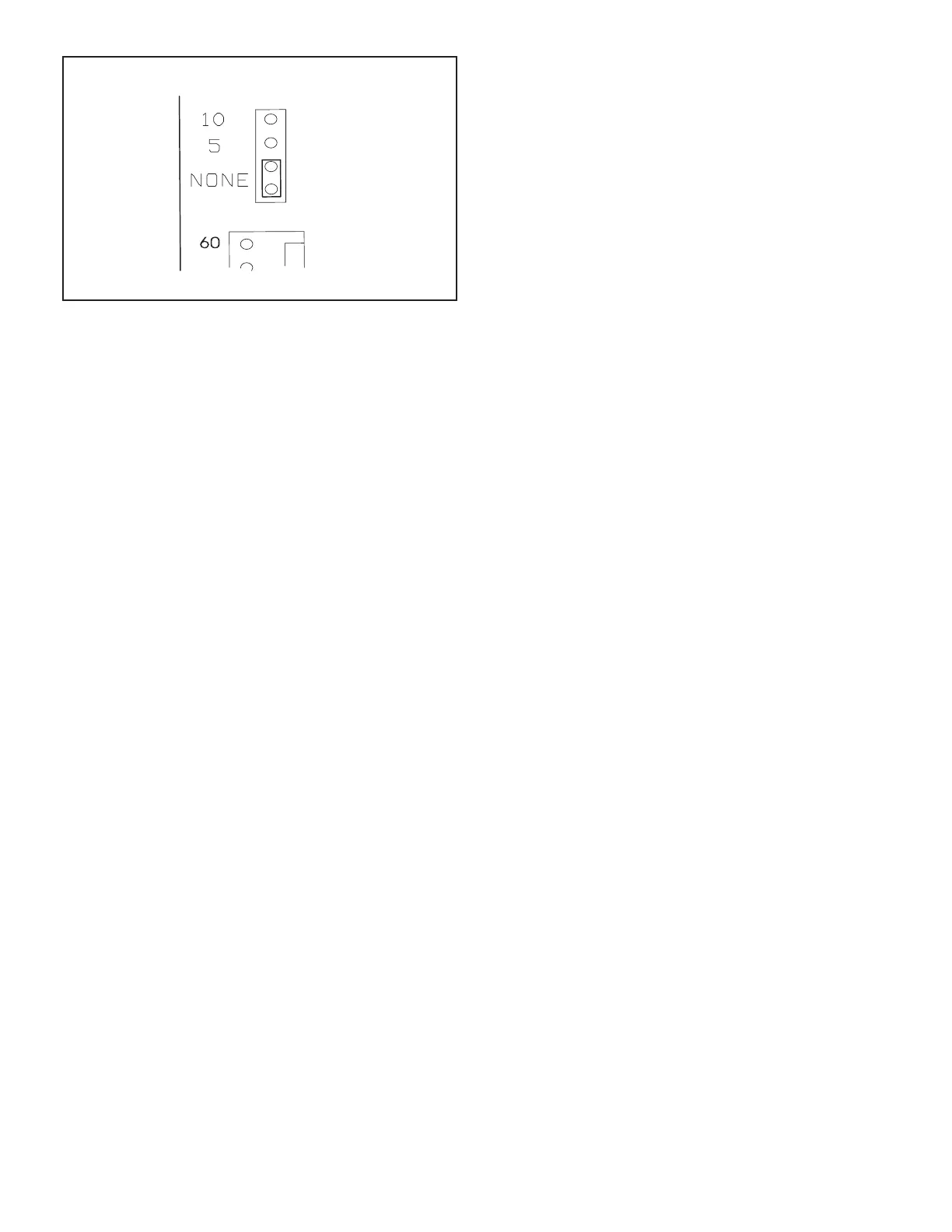

Circulating Airow Adjustments

Cooling Mode

The units are factory set for the highest airow for each

model. Adjustments can be made to the cooling airow by

repositioning the jumper plug marked COOL – A, B, C, D

(see Figure 59). To determine what CFM the motor is de-

livering at any time, count the number of times the amber

LED on the control board ashes. Each ash signies 100

CFM; count the ashes and multiply by 100 to determine

the actual CFM delivered (for example: 5 ashes x 100 =

500 CFM).

Heating Mode

These units are factory set to run at the middle of the heat-

ing rise range as shown on the unit rating plate. If higher

or lower rise is desired, reposition the jumper plug marked

HEAT - A, B, C,(see Figure 59 and table on page 44 for

“Allowable Heating Speeds”. To determine what CFM the

motor is delivering at any time, count the number of times

the amber LED on the control board ashes. Each ash

signies 100 CFM; count the ashes and multiply by 100

to determine the actual CFM delivered (for example: 5

ashes x 100= 500.

Adjust Tap

Airow amounts may be increased or decreased by 10%

by moving the ADJUST jumper plug (see Figure 59) from

the NORM position to the (+) or (-) position. Changes to

the ADJUST tap will aect both cooling and heating air-

ows. The TEST position on the ADJUST tap is not used.

Continuous Blower Operation

The comfort level of the living space can be enhanced

when using this feature by allowing continuous circulation

of air between calls for cooling or heating. The circulation

of air occurs at half the full cooling airow rate.

To engage the continuous blower operation, place the fan

switch on the thermostat into the ON position. A call for fan

from the thermostat closes R to G on the ignition control

board. The control waits for a 1 second thermostat delay

before responding to the call for fan by ramping the circu-

lating blower up to 38% of the cooling speed. When the

call for continuous fan is satised, the control immediately

ramps down the circulating blower.

Loading...

Loading...