Page 32

XP21

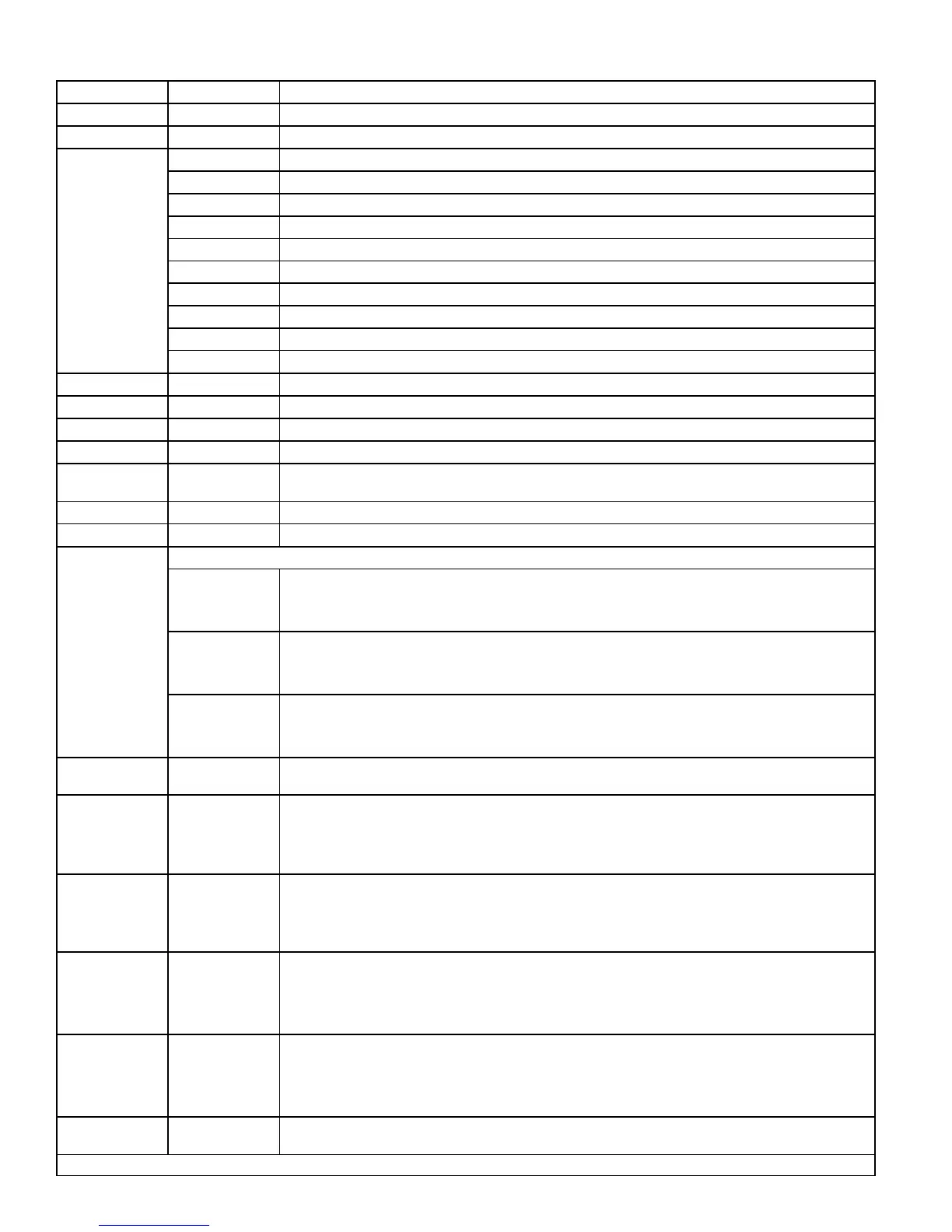

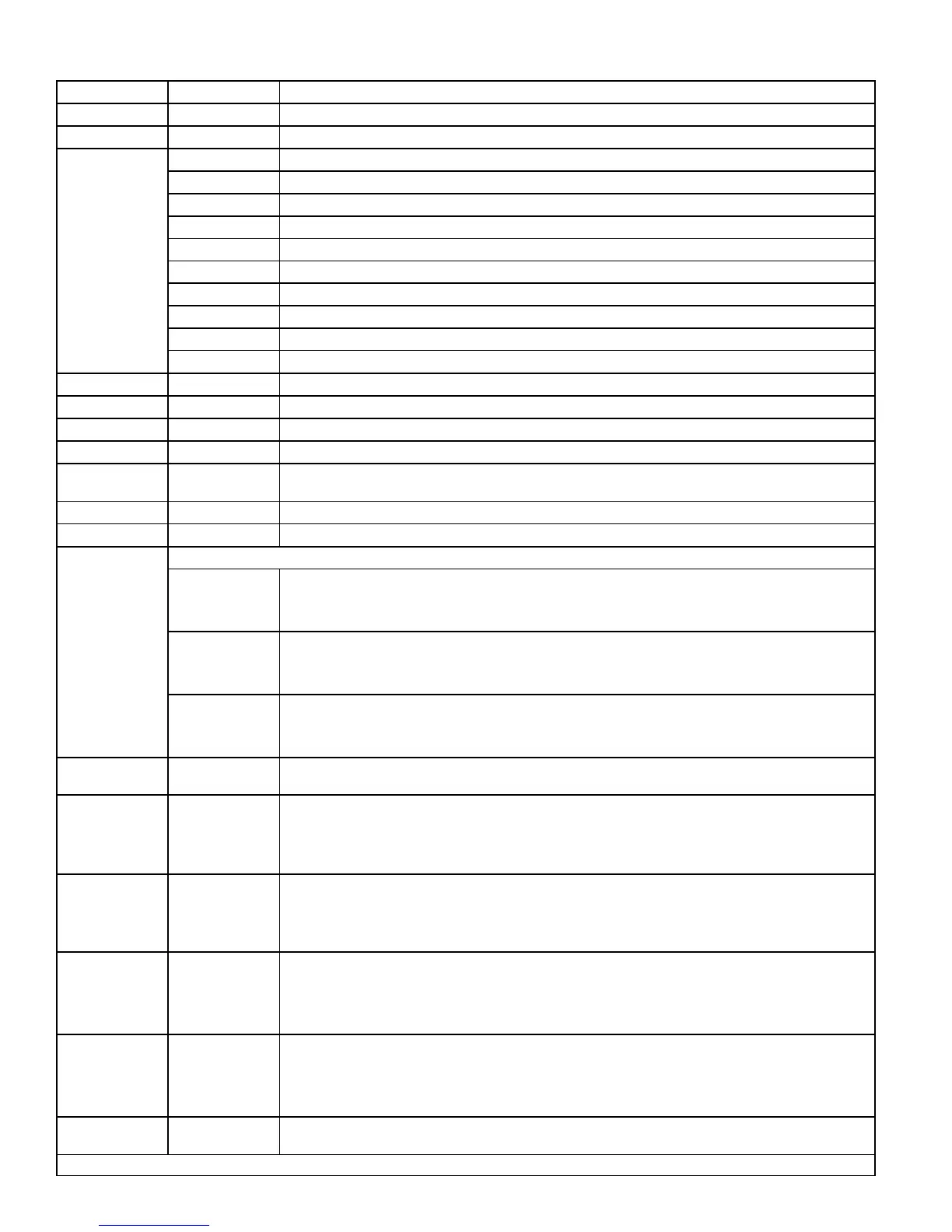

Table 10. Heat Pump Control (A175) Jumper and Terminal Descriptions

Control ID Label Description

E12 PSC Fan 240 VAC output connection for outdoor fan.

E16 PSC Fan 240 VAC input connection for outdoor fan.

E18

W 24VAC output for defrost auxiliary heat output.

L Thermostat service light connection.

Y2 24VAC thermostat input/output for second stage operation of the unit.

Y1 24VAC thermostat input for first stage operation of the unit.

O 24VAC thermostat input for reversing valve operation

DS Humiditrol Input

C 24VAC system common

i− Input/Output − RSBus data low. Used in communicating mode only with compatible indoor thermostat.

i+ Input/Output − RSBus data high. Used in communicating mode only with compatible indoor thermostat.

R 24VAC system power input

E19 and E20 O OUT 24 VAC output connection for reversing valve.

E21 and E22 LO−PS Connection for low−pressure switch (2.4 milliamps @ 18VAC)

E31 and E32 Y1 OUT 24 VAC common output, switched for enabling compressor contactor.

E24 and E25 HS−PS Connection for high−pressure switch.

E26 FAN 1

First Stage and second stage basic and precision dehumidification ECM fan motor 24VDC output connection

1.

E27 FAN 2 Second stage basic and precision dehumidification ECM fan motor 24VDC output connection 2.

E28 FAN C ECM common connection for ECM fan.

E30

Six position square pin header. P4 provides connections for the temperature sensors.

DIS (YELLOW)

PINS 5 and 6

DIS 5 Discharge line temperature sensor supply.

DIS 6 Discharge line temperature sensor return.

Range is 35ºF to 310ºF. Sensor is clipped on a 1/2" copper tube.

AMB (BLACK)

Pins 3 and 4

AMB 3 Outdoor ambient temperature sensor supply.

AMB 4 Outdoor ambient temperature return.

Range is 40ºF to +140ºF

COIL (BROWN)

Pins 1 and 2

COIL 1 Outdoor coil temperature sensor supply.

COIL 2 Outdoor coil temperature sensor return

Range is 40ºF to 140ºF. Sensor is clipped on a 5/16" copper return bend.

E33 Field Test

This jumper allows service personnel to defeat the timed off control, initiate or terminate a defrost and field

programming of unit capacity feature and clears lockouts.

E34 Y2 Solenoid

Keyed plug header used for second−stage compressor output. Sequence for Y2 solenoid coil operations:

Five (5) second delay after Y2 is ON.

Two (2) seconds full 24VDC.

Pulsing voltage to keep solenoid engage

E37 Comp Shift Delay

Two position square pin header. When jumper is installed, a 30−second compressor shift delay is

implemented. It de−energizes the compressor contactor, second−stage solenoid (if on) and the ECM fan

outputs. After the timer expires, the compressor contactor and ECM fan outputs are energized. If no jumper

is installed, it changes the reversing valve direction and de−energizing the outputs immediately. On outdoor

control part number 101796−04 and later, removing jumper also enables the fan cycling option.

E47

50*

70

90

100

Seven position square pin header. E47 provides selection of the defrost terminate temperature based on the

position of the selection jumper. The defrost termination temperature is measured by the RT21

coil tempera-

ture sensor. The jumper termination pin is factory set at 50°F (10°C). If the temperature jumper is not installed,

the default termination temperature is 90°F (32°C).

E48

55

50

45

40 *

(This option is only available on outdoor control part numbers 101796−01 through −03) Five position

square pin header. If the first−stage compressor output is active in heating mode and the outdoor ambient

temperature is below the selected compressor lock−in temperature, the second−stage compressor solenoid

outputs will be energized without the Y2 input. If the jumper is not present on E48, the default lock−in

temperature of 40ºF will be used.

W1 Short DS To R

Cut for Humiditrol (EDA) application. This sets the outdoor fan speed to predefined speed. See table 17 for

set speed based on unit capacity size. Use only in two−stage units.

* Factory default setting

Loading...

Loading...