Page 25

DIP Switch Settings

NOTE - All communicating settings are set at the commu-

nicating thermostat. See thermostat installation instruc-

tion. In a communication system all DIP switch and clippa-

ble link settings are ignored. For conventional thermostats

proceed with DIP switch and clippable link settings as out-

lined in the following.

Heating Operation DIP Switch Settings

Switch 1 -- Thermostat Selection -- This unit may be

used with either a single-stage or two-stage thermostat.

The thermostat selection is made using a DIP switch

which must be properly positioned for the particular appli-

cation. The DIP switch is factory-positioned for use with a

twostage thermostat. If a single-stage thermostat is to be

used, the DIP switch must be repositioned.

a. Select “OFF” for two-stage heating operation controlled by a

two-stage heating thermostat (factory setting);

b. Select “ON” for two-stage heating operation controlled by

a single-stage heating thermostat. This setting provides a

timed delay before second-stage heat is initiated.

Switch 2 -- Second Stage Delay (Used with Single-

Stage Thermostat Only) -- This switch is used to de-

termine the second stage on delay when a single-stage

thermostat is being used. The switch is factory-set in the

OFF position, which provides a 7-minute delay before

secondstage heat is initiated. If the switch is toggled to

the ON position, it will provide a 12-minute delay before

secondstage heat is initiated. This switch is only activated

when the thermostat selector jumper is positioned for SIN-

GLEstage thermostat use.

Switches 3 and 4 -- Blower-O Delay -- The blower-on

delay of 30 seconds is not adjustable. The blower-o de-

lay (time that the blower operates after the heating de-

mand has been satised) can be adjusted by moving

switches 3 and 4 on the integrated control. The unit is

shipped from the factory with a blower-o delay of 90 sec-

onds. The blower o delay aects comfort and is adjust-

able to satisfy individual applications. Adjust the blower

o delay to achieve a supply air temperature between 90°

and 110°F at the exact moment that the blower is de-en-

ergized. Longer o delay settings provide lower supply

air temperatures; shorter settings provide higher supply

air temperatures.TABLE 6 provides the blower o timings

that will result from dierent switch settings.

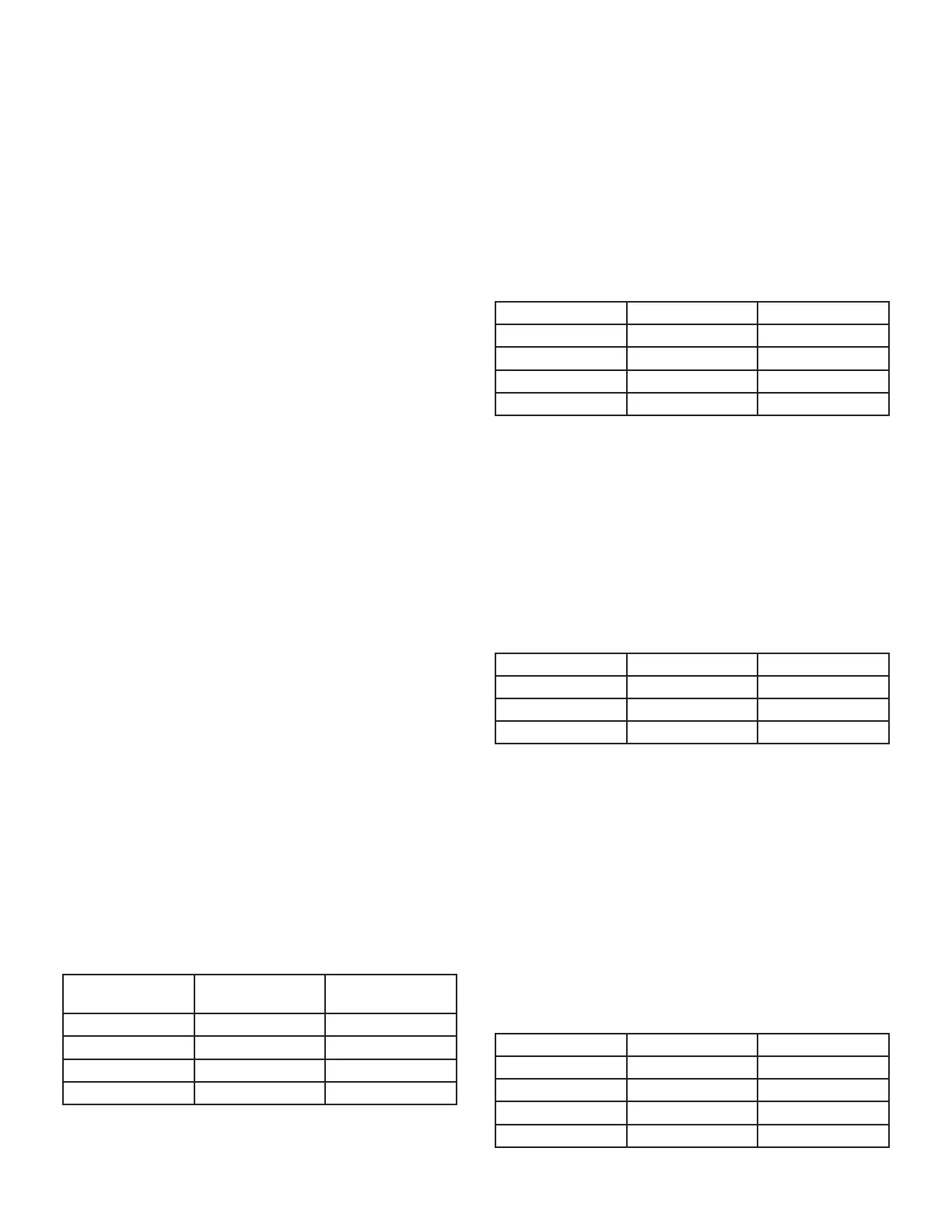

TABLE 6

Blower O Delay Switch Settings

Blower O Delay

(Seconds)

Switch 3 Switch 4

60 On O

90 (factory) O O

120 O O

180 On O

Indoor Blower Operation DIP Switch Settings

Switches 5 and 6 -- Cooling Mode Blower Speed --

The unit is shipped from the factory with the dip switch-

es positioned for high speed (4) indoor blower motor op-

eration during the cooling mode. TABLE 7 provides the

cooling mode blower speeds that will result from dierent

switch settings. Switches 5 and 6 set the blower cfm for

secondstage cool. The integrated control automatically

ramps down to 70% of the second-stage cfm for rst-stage

cfm. Refer to blower tables for corresponding cfm values.

TABLE 7

Cooling Mode Blower Speeds

Speed Switch 5 Switch 6

Low On On

Medium Low O On

Medium High On O

High (Factory) O O

Switches 7 and 8 -- Cooling Blower Speed Adjustment

-- The unit is shipped from the factory with the dip switches

positioned for NORMAL (no) adjustment. The dip switches

may be positioned to adjust the blower speed by +10% or

-10% to better suit the application. TABLE 8 below pro-

vides blower speed adjustments that will result from dier-

ent switch settings. Refer to blower tables for correspond-

ing cfm values.

TABLE 8

Cooling Blower Speed Adjustment

Adjustment Switch 7 Switch 8

+10% (approx.) On O

Factory Default O O

-10% (approx.) O On

Switches 9 and 10 -- Cooling Mode Blower Speed

Ramping -- Blower speed ramping may be used to en-

hance dehumidication performance. The switches are

factory set at option A which has the greatest eect on de-

humidication performance. TABLE 9 provides the cooling

mode blower speed ramping options that will result from

dierent switch settings. The cooling mode blower speed

ramping options are detailed below.

NOTE - The o portion of the selected ramp prole also

applies during heat pump operation in dual fuel applica-

tions.

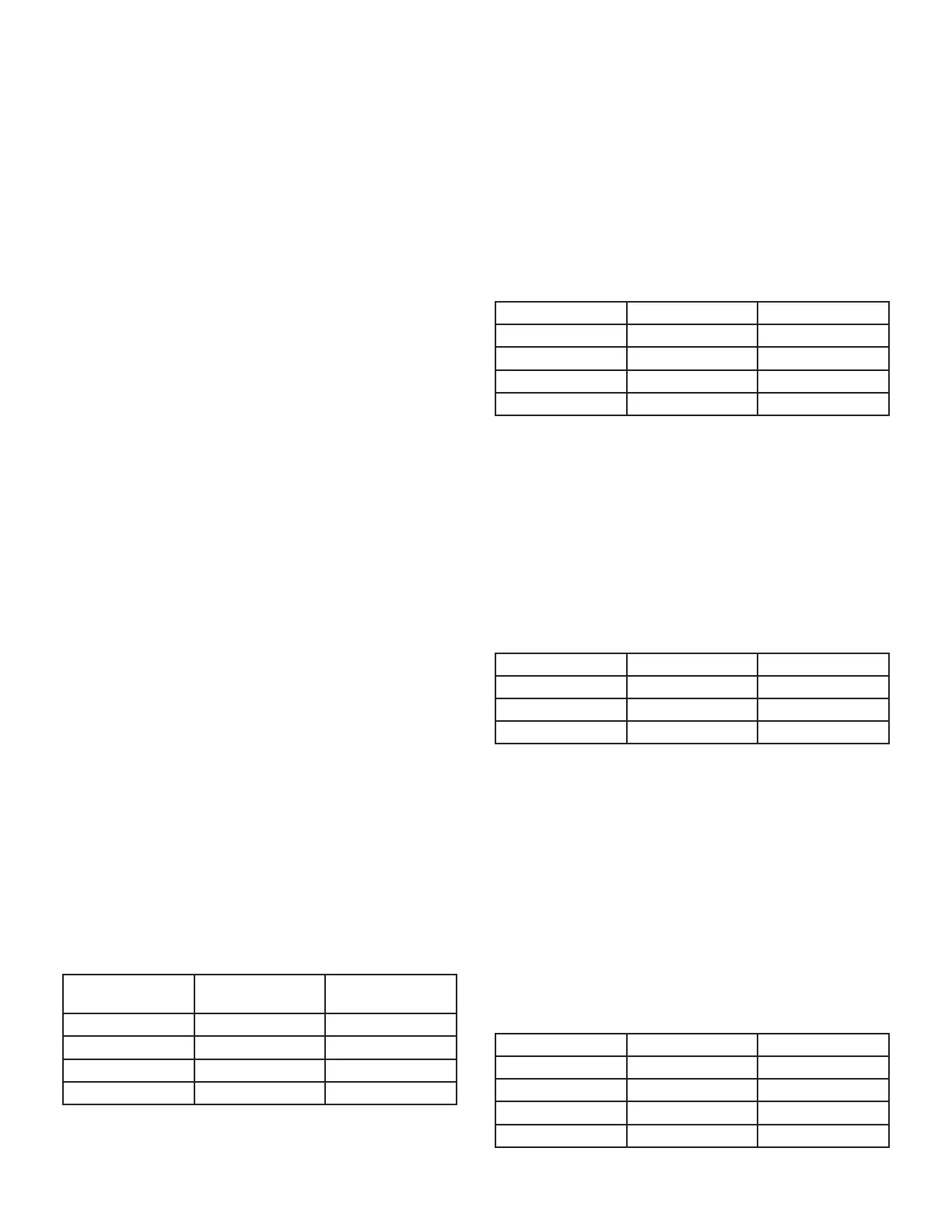

TABLE 9

Cooling Mode Speed Ramping

Ramping Option Switch 9 Switch 10

A (factory) O O

B O On

C On O

D On On

Loading...

Loading...