Page 44

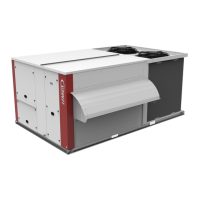

A-Heat Exchanger and Burners

Cleaning the Heat Exchanger and Burners

Figure 26 (-01 through -04 models) and Figure 27 (-05

and later models.)

NOTE - Use papers or protective covering in front of the

furnace during cleaning.

1 - Turn o both electrical and gas power supplies to

furnace.

2 - -05 models and later - remove the air intake

assembly from outside the cabinet. The assembly

is not secured with screws or glue and will remove

with ease. See Figure 28.

3 - Remove ue pipe and top cap (some applications

top cap can remain) from the unit.

4 - Label the wires from gas valve, thermal switch,

primary limit switch and make-up box then

disconnect them.

5 - Remove the screws that secure the combustion air

inducer to the collector box.

6 - Disconnect gas supply piping. Remove the screw

securing the air fuel plenum and remove along with

the air intake assembly as one component.

7 - Remove screws from both sides, top and bottom of

vestibule panel.

8 - Remove heat exchanger. It may be necessary

to spread cabinet side to allow more room. If so,

remove ve screws from the left side or right side of

cabinet. See Figure 28.

9 - Back wash using steam. Begin from the burner

opening on each tube. Steam must not exceed

275°F.

10 - To clean burner, remove from the air gas plenum

and run a vacuum cleaner over the face of burner.

Visually inspect inside the burner for any blockage

caused by foreign matter. Remove any blockage.

Figure 29 shows burner detail. Replace gasket

between burner plate and air fuel plenum then

re-install burner plate.

11 - To clean the combustion air inducer visually inspect

and using a wire brush clean where necessary. Use

compressed air to clean o debris and any rust.

Screen

2” PVC Pipe 2 ½”

Length

Elbow

Reducer

Air Intake Pipe Connections Upflow

-05 and later models

Note - Assembly may be rotated

to accommodate installation

4 ½”

FIGURE 29

12 - Reinstall heat exchanger in vestibule. (Replace the

ve screws in the cabinet from step 10 if removed).

13 - Reinstall the air fuel plenum and air intake assembly.

Re-install the combustion air inducer assembly.

Make note to re-install all screws. Failure to replace

all screws may cause leaks.

14 - Reconnect all wires.

15 - Reconnect top cap and vent pipe to combustion air

inducer outlet.

16 - Reconnect gas supply piping.

17 - -05 models and later, using a rubber mallet

reconnect the air intake assembly removed from

the outside of the cabinet in step 2.

18 - Turn on power and gas supply to unit.

19 - Set thermostat and check for proper operation.

20 - Check all piping connections, factory and eld, for

gas leaks. Use a leak detecting solution or other

preferred means.

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, ame or other sources of ignition

to check for gas leaks.

21 - If a leak is detected, shut gas and electricity o and

repair leak.

22 - Repeat steps 17 and 18 until no leaks are detected.

23 - Replace access panel.

Remove 5 screws if necessary

(cabinet for reference only)

1

2

3

4

5

FIGURE 30

Loading...

Loading...