Troubleshooting and fault elimination

Fault messages

Causes and remedies

12

248

EDBCSXA064 EN 3.2

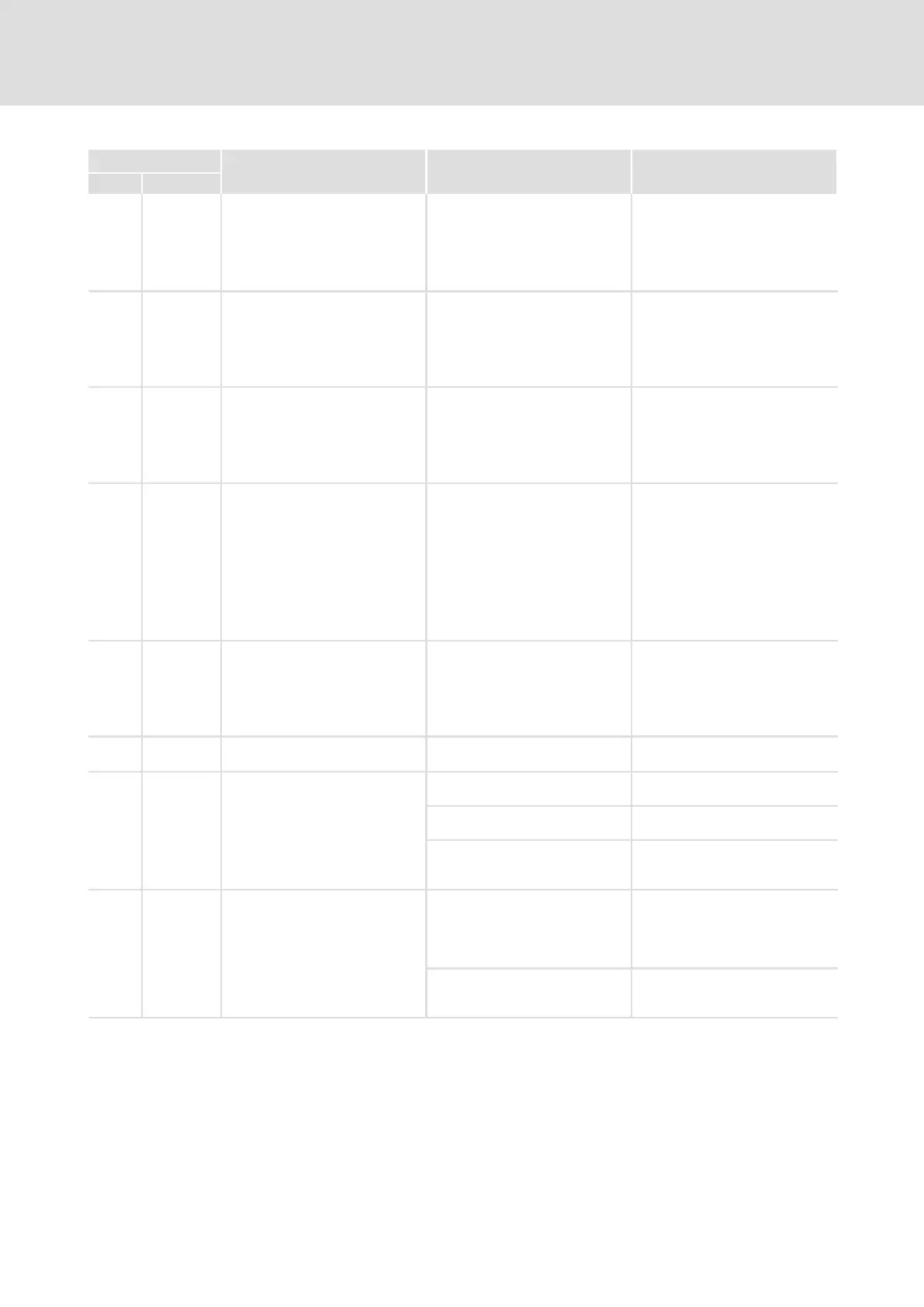

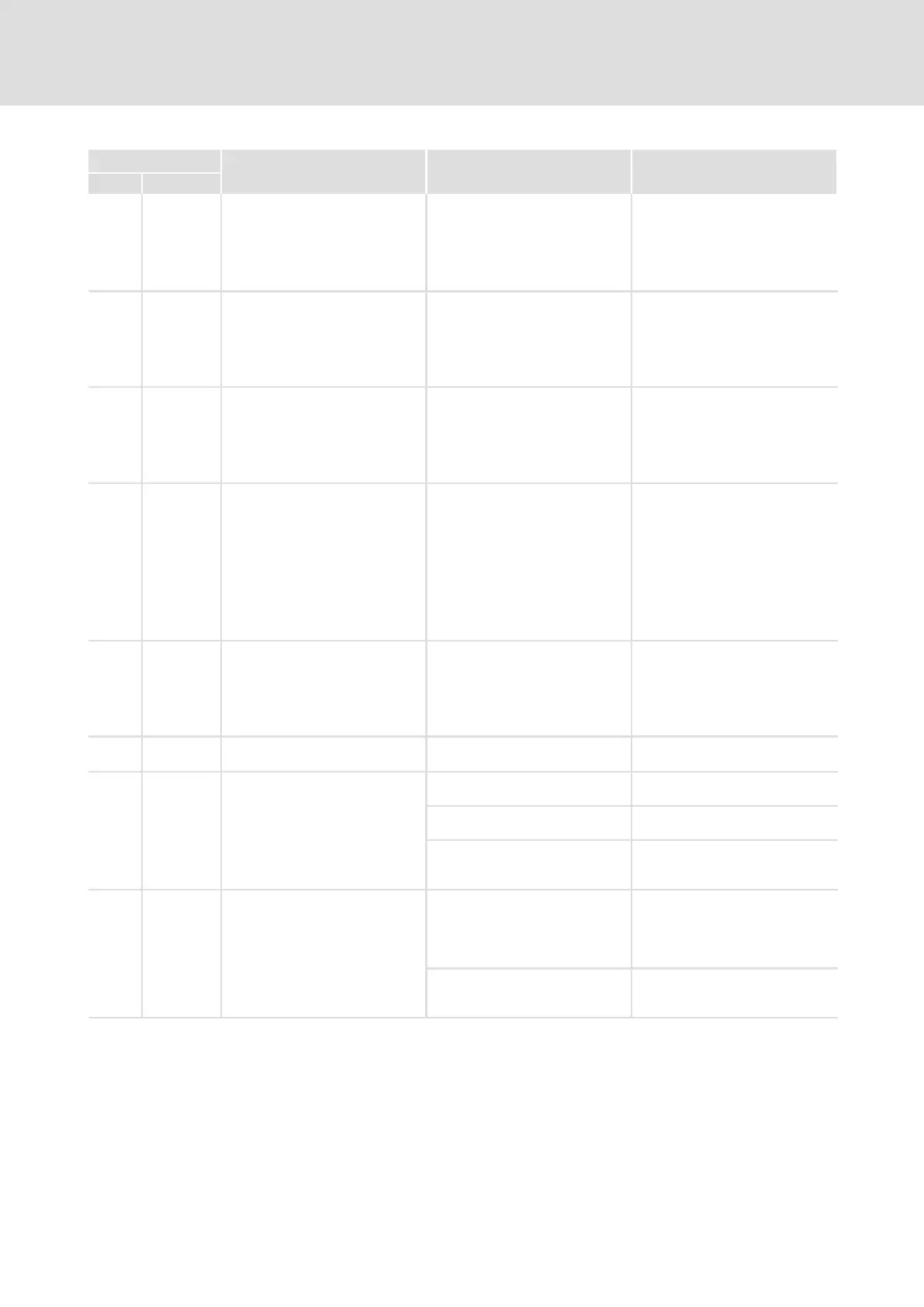

RemedyCauseDescriptionFault message RemedyCauseDescription

DisplayNo.

x062 CE1 Communication error on the

process data input object

CAN1_IN

CAN1_IN object receives faulty

data or communication is

interrupted.

l Check wiring at X4.

l Check sender.

l Increase monitoring time

under C0357/1, if necessary.

l Switch off monitoring

(C0591 = 3).

x063 CE2 Communication error on the

process data input object

CAN2_IN

CAN2_IN object receives faulty

data or communication is

interrupted.

l Check wiring at X4.

l Check sender.

l Increase monitoring time

under C0357/2, if necessary.

l Switch off monitoring

(C0592 = 3).

x064 CE3 Communication error on the

process data input object

CAN3_IN

CAN3_IN object receives faulty

data or communication is

interrupted.

l Check wiring at X4.

l Check sender.

l Increase monitoring time

under C0357/3, if necessary.

l Switch off monitoring

(C0593 = 3).

x065 CE4 BUS−OFF state of system

bus (CAN), interface X4

The module has received too

many incorrect telegrams via the

system bus (CAN) and has

disconnected from the bus

l Check wiring at X4: bus

termination available?

l Check screen contact of the

cables.

l Check PE connection.

l Check bus load, reduce baud

rate, if necessary (Observe

cable length!)

l Switch off monitoring

(C0595 = 3).

x066 CE5 System bus (CAN) time−out

(communication error of gateway

function), interface X4

For remote parameterisation

(C0370, C0371) via system bus

(CAN):

l Slave does not respond.

l Communication monitoring

time has been exceeded.

l Check wiring at X4.

l Check CAN bus configuration.

l Switch off monitoring

(C0603 = 3).

0070 U15 Undervoltage of internal 15 V

voltage supply

Check voltage supply.

0071 CCr System failure

Strong interference injection on

the control cables

Screen control cables

Ground or earth loops in the

wiring

l Check wiring

l Check PE connection

After troubleshooting: Deenergise

the device completely (disconnect

24 V supply, discharge DC bus)!

0072 PR1 Checksum error in parameter

set 1

CAUTION: The Lenze setting is

loaded automatically!

l Fault when loading a

parameter set.

l Interruption while

transmitting the parameter set

via keypad.

l Set the required parameters

and store them under C0003 =

1.

l As to PLC devices, check the

use of pointers.

The stored parameters are

incompatible with the loaded

software version.

Store the parameter set under

C0003 = 1 first to allow for a

faults reset.

x: 0 = TRIP, 1 = Message, 2 = Warning, 3 = FAIL−QSP

Loading...

Loading...