Maintenance/repair

Maintenance operations

Spring−operated brakes

8

42

Lenze ¯ BA 33.0005 ¯ 5.0

Wear on spring−applied brakes

The used spring−applied brakes have a low rate of wear and are designed for long

maintenance intervals.

However, the friction lining, the teeth between the brake rotor and the hub, and also the

braking mechanism are naturally subject to function−related wear which depends on

the application case (see table). In order to ensure safe and problem−free operation, the

brake must therefore be checked and maintained regularly and, if necessary, replaced

(see brake maintenance and inspection).

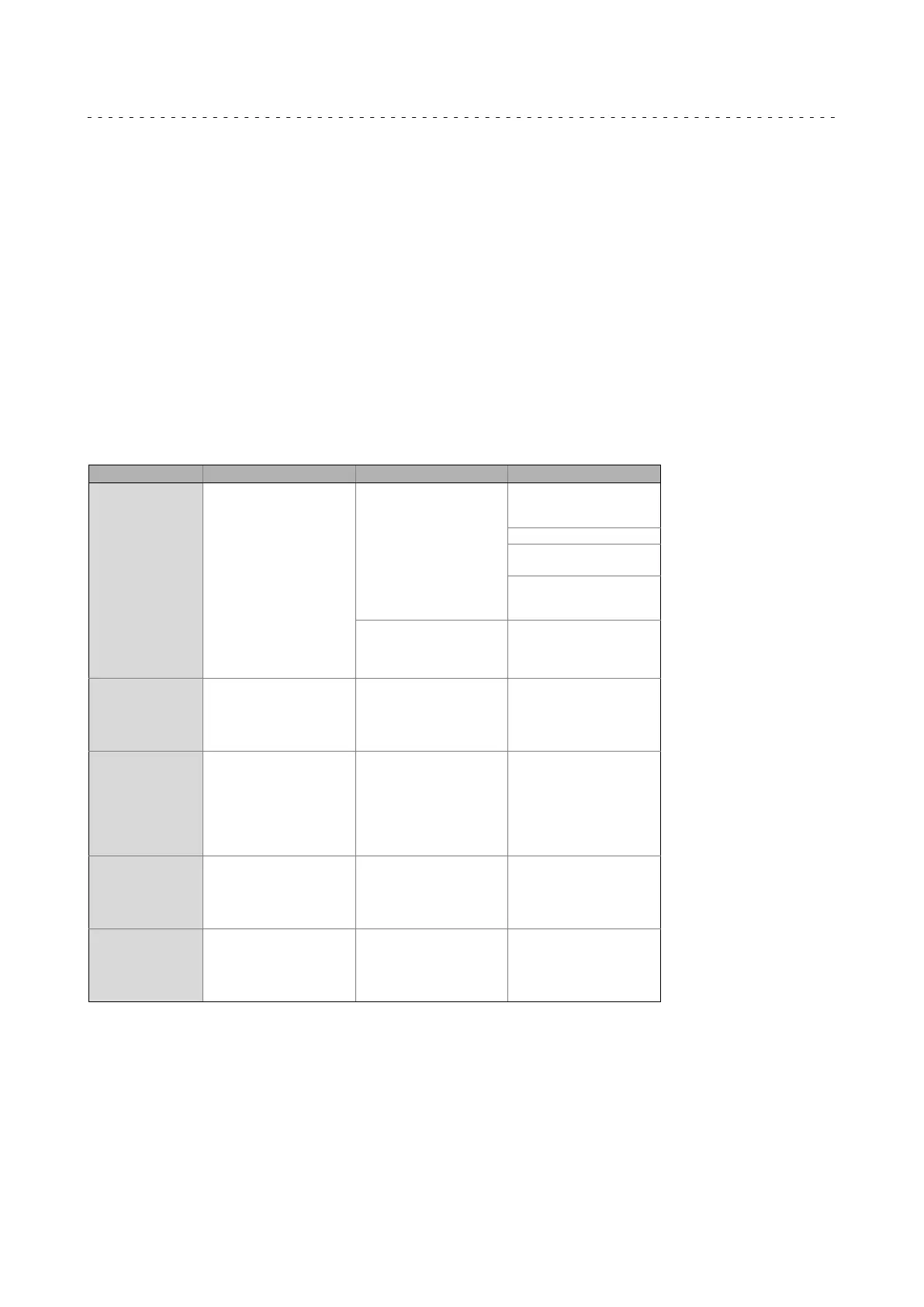

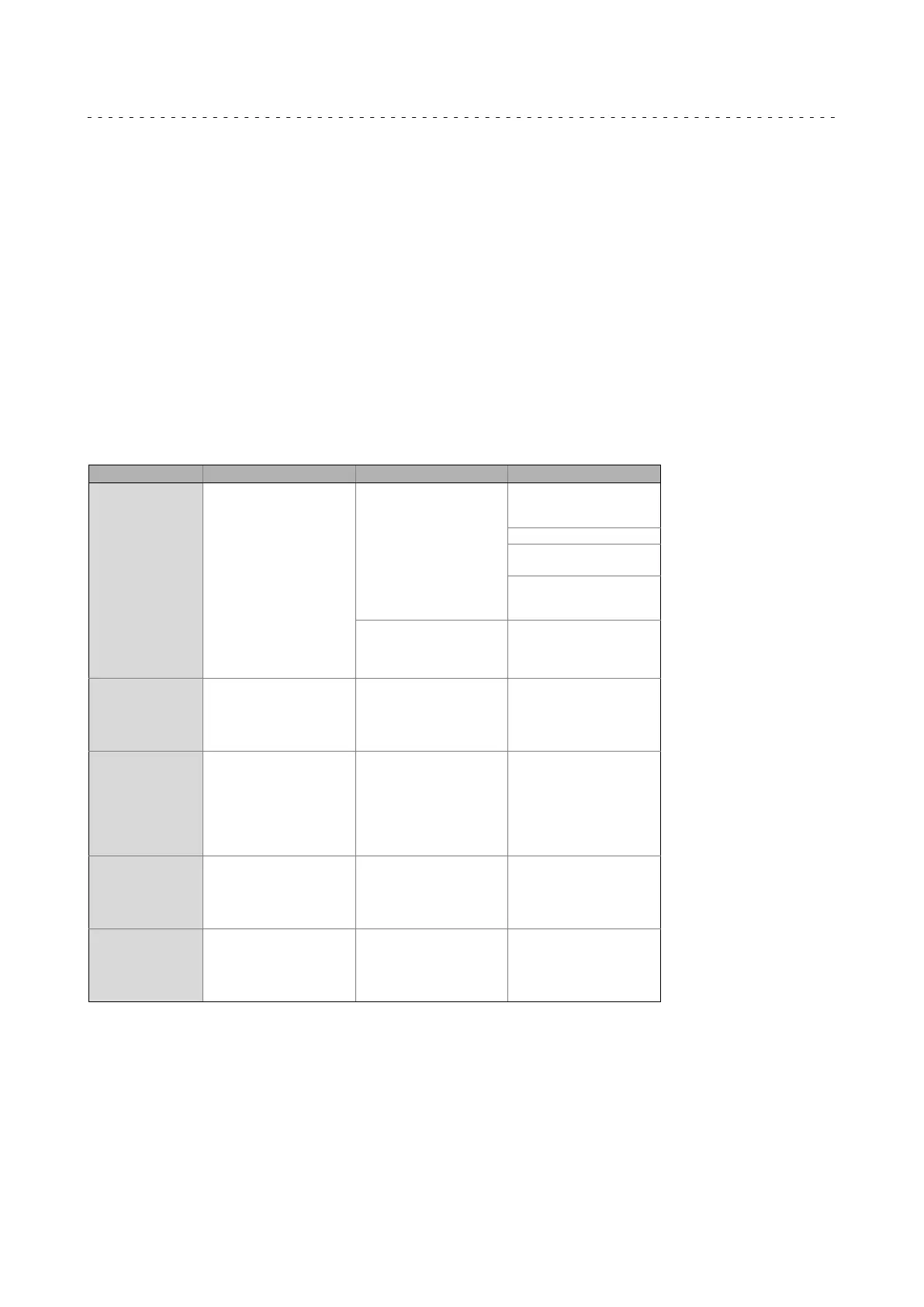

The following table describes the different causes of wear and their effect on the

components of the spring−applied brake. In order to calculate the useful life of the rotor

and brake and determine the maintenance intervals to be prescribed, the relevant

influencing factors must be quantified. The most important factors are the applied

friction energy, the starting speed of braking and the switching frequency. If several of

the indicated causes of wear on the friction lining occur in an application, their effects

are to be added together.

Component Effect Influencing factors Cause

Friction lining Wear on the friction lining Applied friction energy

Braking during operation

(impermissible, holding

brakes!)

Emergency stops

Overlapping wear when

the drive starts and stops

Active braking by the drive

motor with the help of the

brake (quick stop)

Number of start−stop

cycles

Starting wear if motor is

mounted in a position

with the shaft vertical,

even if the brake is open

Armature plate and

flange

Running−in of armature

plate and flange

Applied friction energy Friction between the brake

lining and the armature

plate or flange e.g. during

emergency braking or

service brake operation

Teeth of the brake

rotor

Teeth wear (primarily at

the rotor end)

Number of start−stop

cycles,

Level of the braking

torque,

Dynamics of the

application,

Speed fins in operation

Relative movement and

impacts between brake

rotor and brake hub

Armature plate

bracket

Armature plate, cap screws

and bolts are deflected

Number of start−stop

cycles,

Level of braking torque

Load changes and impacts

due to reversal error

during interaction

between armature plate,

cap screws and guide bolts

Springs Fatigue failure of the

springs

Number of switching

operations of the brake

Axial load cycle and

shearing stress on the

springs due to radial

reversing error of the

armature plate

Tab. 2 Causes for wear

Loading...

Loading...