Maintenance/repair

Maintenance operations

Spring−operated brakes

8

41

Lenze ¯ BA 33.0005 ¯ 5.0

8.2.3 Spring−operated brakes

To ensure safe and trouble−free operation, spring−applied brakes must be checked and

maintained at regular intervals. Servicing can be made easier if good accessibility of the

brakes is provided in the plant. This must be considered when installing the drives in the

plant.

Primarily, the necessary maintenance intervals for industrial brakes result from the load

during operation. When calculating the maintenance interval, all causes for wear must

be taken into account, (( 42). For brakes with low loads such as holding brakes with

emergency stop, we recommend a regular inspection at a fixed time interval. To reduce

the cost, the inspection can be carried out along with other regular maintenance work

in the plant if necessary.

If the brakes are not maintained, failures, production losses or damage to the system

may occur. Therefore, a maintenance concept adapted to the particular operating

conditions and brake loads must be defined for every application. For the spring−applied

brakes, the maintenance intervals and maintenance operations listed in the below

table must be provided. The maintenance operations must be carried out as described

in the detailed descriptions.

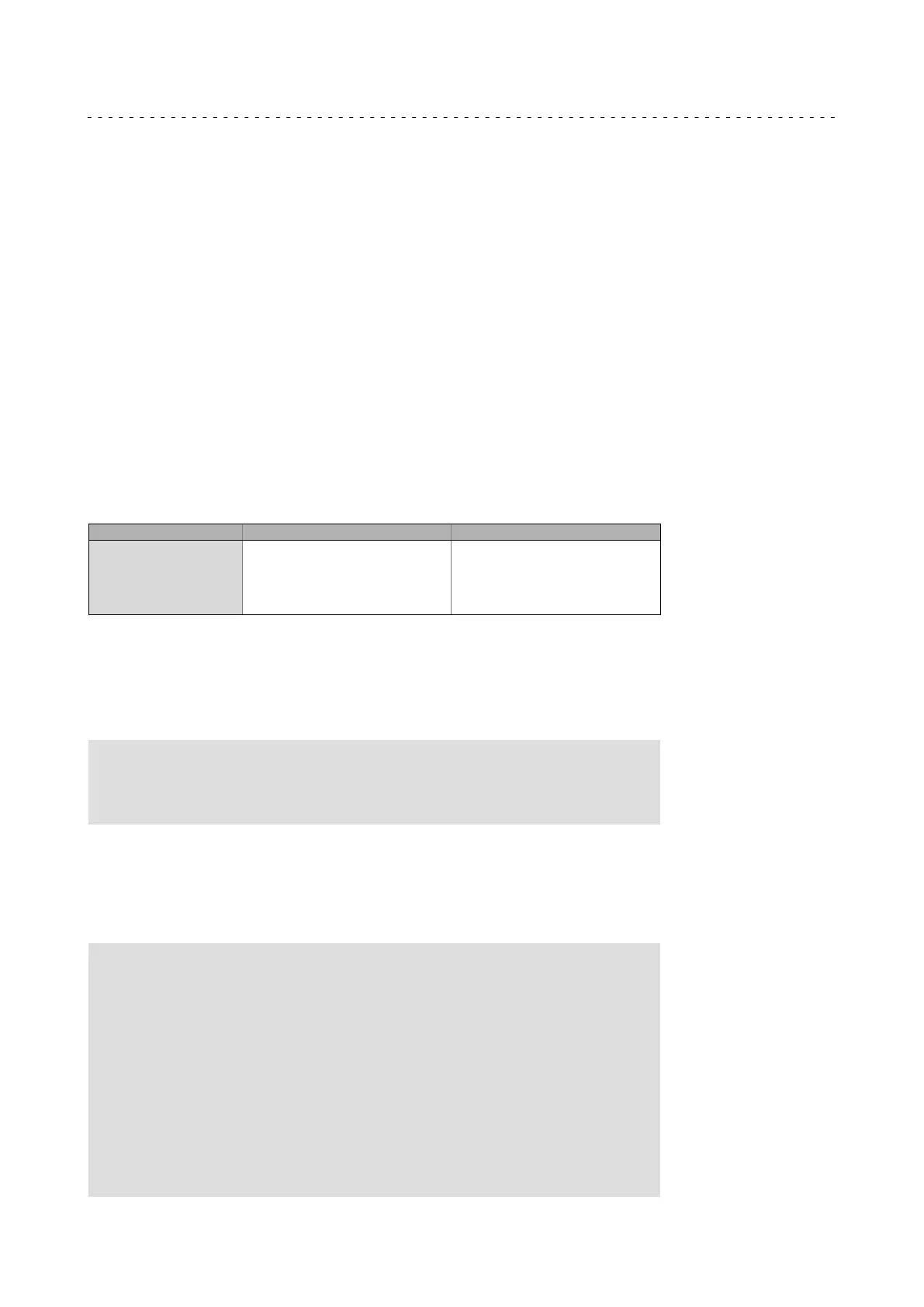

Type Service brake Holding brake with emergency stop

Spring−applied brake ¯ according to service life

calculation

¯ otherwise every six months

¯ after 4,000 operating hours at the

latest

¯ at least every two years

¯ after 1 million cycles at the latest

¯ provide shorter intervals in the

case of frequent emergency stops

8.3 Maintenance operations

8.3.1 Motor

Stop!

¯ Make sure that no foreign bodies can enter the inside of the motor!

¯ Do not remove plugs when voltage is being applied!

8.3.2 Spring−operated brakes

The brake is mounted to the N−end shield of the motor. Remove the fan cover or blower

unit or the encoder, if available, to check, maintain, or set the brake.

Note!

Brakes with defective armature plates, cheese head screws, springs or

counter friction faces must always be replaced completely.

Generally observe the following for inspections and maintenance works:

¯ Remove oil and grease linked impurities using brake cleaning agents, if

necessary, replace brake after identifying the cause of the

contamination. Dirt deposits in the air gap between stator and

armature plate impair the function of the brake and must be removed.

¯ After replacing the rotor, the original braking torque will not be

reached until the run−in operation of the friction surfaces has been

completed. After replacing the rotor, run−in armature plates and

counter friction faces have an increased initial rate of wear.

Loading...

Loading...