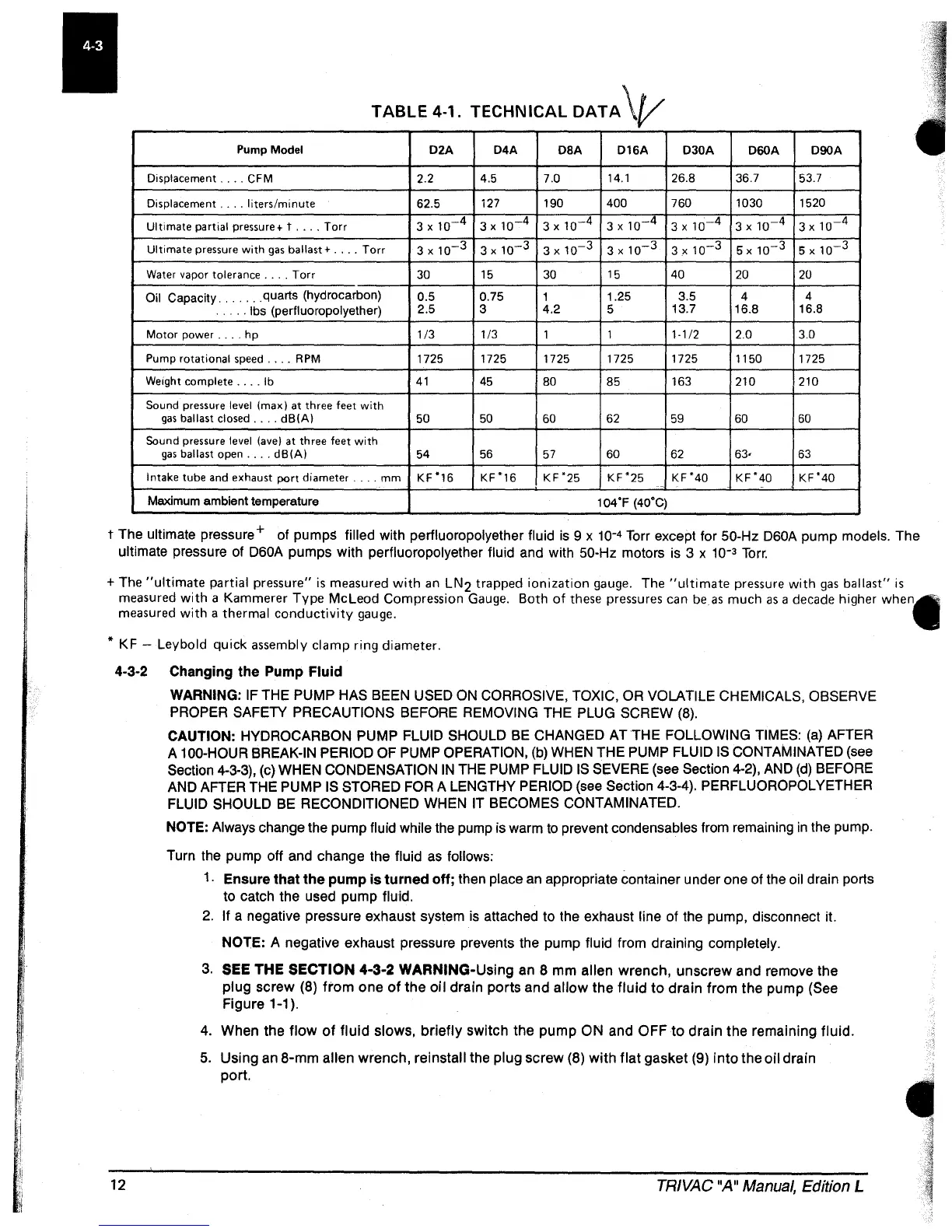

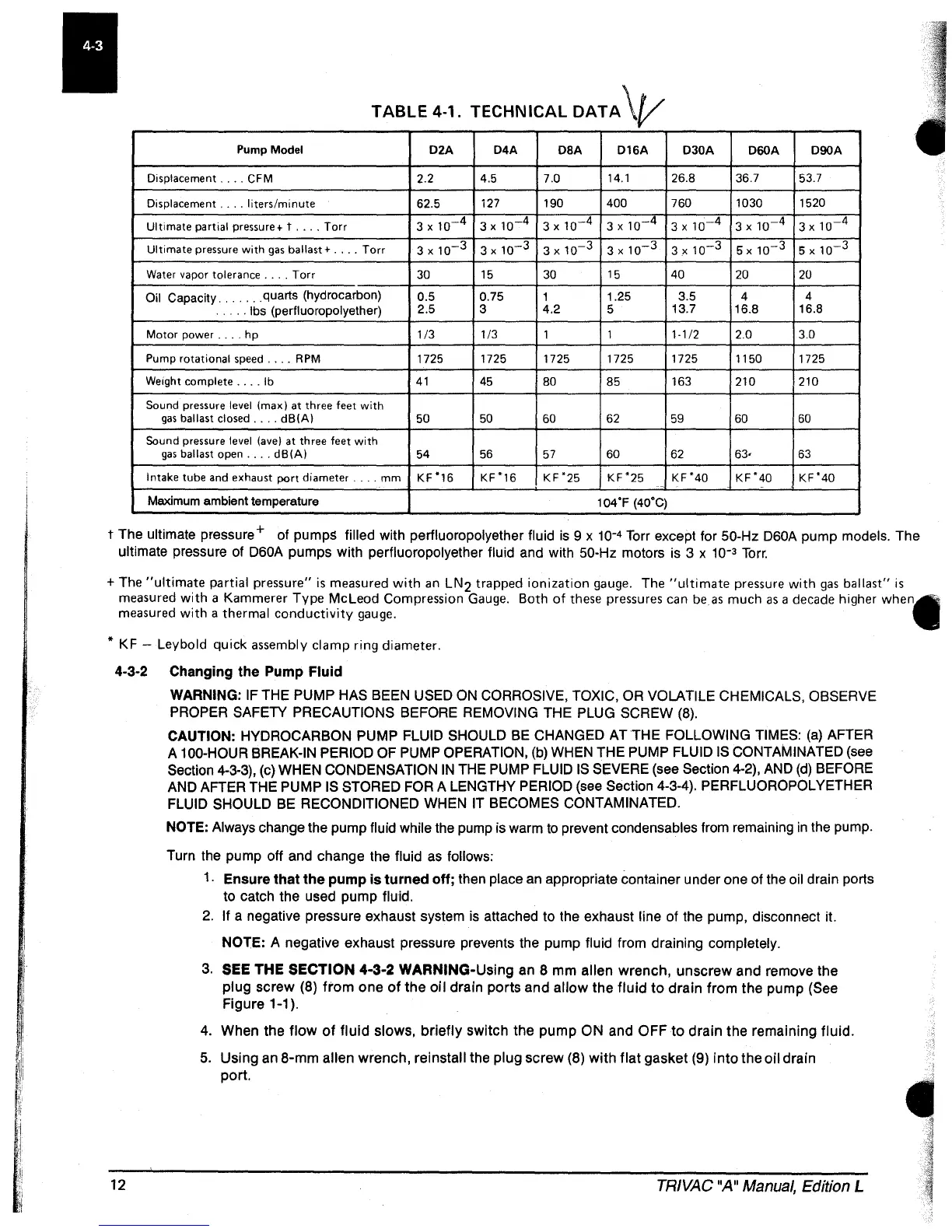

TABLE 4-1. TECHNICAL

DATA

\f/

Pump Model

D2A

D4A

DBA

D1GA

D30A

D60A

D90A

Displacement

....

CFM

2.2

4.5

7.0

14.1 26.8 36.7 53.7

Displacement

....

I

iters/minute

62.5

127 190

400

760

1030

1520

Ultimate

partial pressure+ t

....

Torr

3 x

10-

4

3 x

10-

4

3 x

10-

4

3 x

10-

4

3 x

10-

4

3 x

10-

4

3 x

10-

4

Ultimate

pressure

with

gas

ballast +

....

Torr

3 x

10-

3

3 x

10-

3

3 x

10-

3

3 x

10-

3

3,x

10-

3

5 x

10-

3

5 x

10-

3

Water vapor

tolerance

....

Torr

30 15 30

15

40

20 20

Oil

Capacity.

,

.....

quarts

(hydrocarbon)

0.5

0.75

1

1.25

3.5

4

4

...

Ibs

(perfluoropolyether)

2.5

3

4.2

5

13.7

16.8

16.8

Motor

power

....

hp

1/3

1/3

1 1 1·1/2

2.0 3.0

Pump rotational

speed

....

RPM

1725

1725 1725

1725 1725 1150

1725

Weight

complete

....

Ib

41

45 80

85

163

210

210

Sound

pressure level (max) at three feet

with

gas

ballast closed

....

dB(A)

50

50 60 62 59

60

60

Sound pressure level (ave) at three feet

with

gas

ballast open

....

dB(A)

54

56

57

60

62 63·

63

Intake tube and exhaust

port

diameter

....

mm

KF'16

KF'16

KF

*25

KF'25

KF*40

KF'40

KF*40

.

Maximum

ambient

temperature

104°F

(40°C)

t The ultimate pressure + of pumps filled with perfluoropolyether fluid

is

9 x

10-

4

Torr

except for 50-Hz D60A pump models. The

ultimate pressure of

D60A pumps with perfluoropolyether fluid and with 50-Hz motors is 3 x 10-

3

Torr.

+

The

"ultimate partial pressure"

is

measured

with

an

LN2 trapped ionization

gauge.

The

"ultimate

pressure

with

gas

ballast"

is

measured

with a Kammerer Type McLeod Compression

Gauge.

Both

of

these

pressures

can

be,as

much

as

a

decade

higher

When.

measured

with a thermal conductivity

gauge.

* KF - Leybold quick assembly clamp ring diameter.

4-3-2 Changing

the

Pump

Fluid

12

WARNING:

IF

THE PUMP HAS BEEN USED

ON

CORROSIVE, TOXIC, OR VOLATILE CHEMICALS, OBSERVE

PROPER SAFETY

PRECAUTIONS BEFORE REMOVING THE PLUG SCREW

(8).

CAUTION: HYDROCARBON PUMP FLUID SHOULD BE CHANGED

ATTHE

FOLLOWING TIMES:

(a)

AFTER

A

100-HOUR BREAK-IN PERIOD OF PUMP OPERATION,

(b)

WHEN THE PUMP FLUID

IS

CONTAMINATED

(see

Section 4-3-3), (c) WHEN CONDENSATION

IN

THE PUMP FLUID

IS

SEVERE (see Section 4-2), AND

(d)

BEFORE

AND AFTER THE PUMP

IS

STORED FOR A LENGTHY PERIOD (see Section 4-3-4). PERFLUOROPOL YETHER

FLUID SHOULD BE RECONDITIONED WHEN IT BECOMES CONTAMINATED.

NOTE:

Always change the pump fluid while the pump is warm

to

prevent condensables from remaining

in

the pump.

Turn the pump off and change the fluid as

follows:

1.

Ensure

that

the

pump

is

turned

off; then place

an

appropriate container under one of the oil drain ports

to catch the used pump fluid.

2.

If a negative pressure exhaust system is attached to the exhaust line of the pump, disconnect it.

NOTE: A negative exhaust pressure prevents the pump fluid from draining completely.

3.

SEE THE

SECTION

4-3-2 WARNING-Using an 8 mm allen wrench, unscrew and remove the

plug screw (8)

from

one

of

the

oil drain ports and allow the

fluid

to

drain

from

the pump (See

Figure

1-1).

4. When the

flow

of

fluid

slows,

briefly

switch the pump ON and OFF

to

drain the remaining fluid.

5.

Using an 8-mm allen wrench, reinstall the plug screw (8)

with

flat gasket (9)

into

the oil drain

port.

TRIVAC

"A"

Manual,

Edition L

Loading...

Loading...