C8b

CONTINUED

until

the

long pin (65) forces

the

other

short

pin (the

one

that

aligns

the

front

end

plate (44) and

the

second

stage

pump

cylinder)

to

fall

out,

and

then

the

long pin also falls

out

of

the

front-end-

plate

alignment

hole (see Figure 5-5).

c.

Repeat

Steps

C-8a

and

C-8b

for

the

two

short

and

one

long cylindrical pins

on

the

other

side

of

the

module.

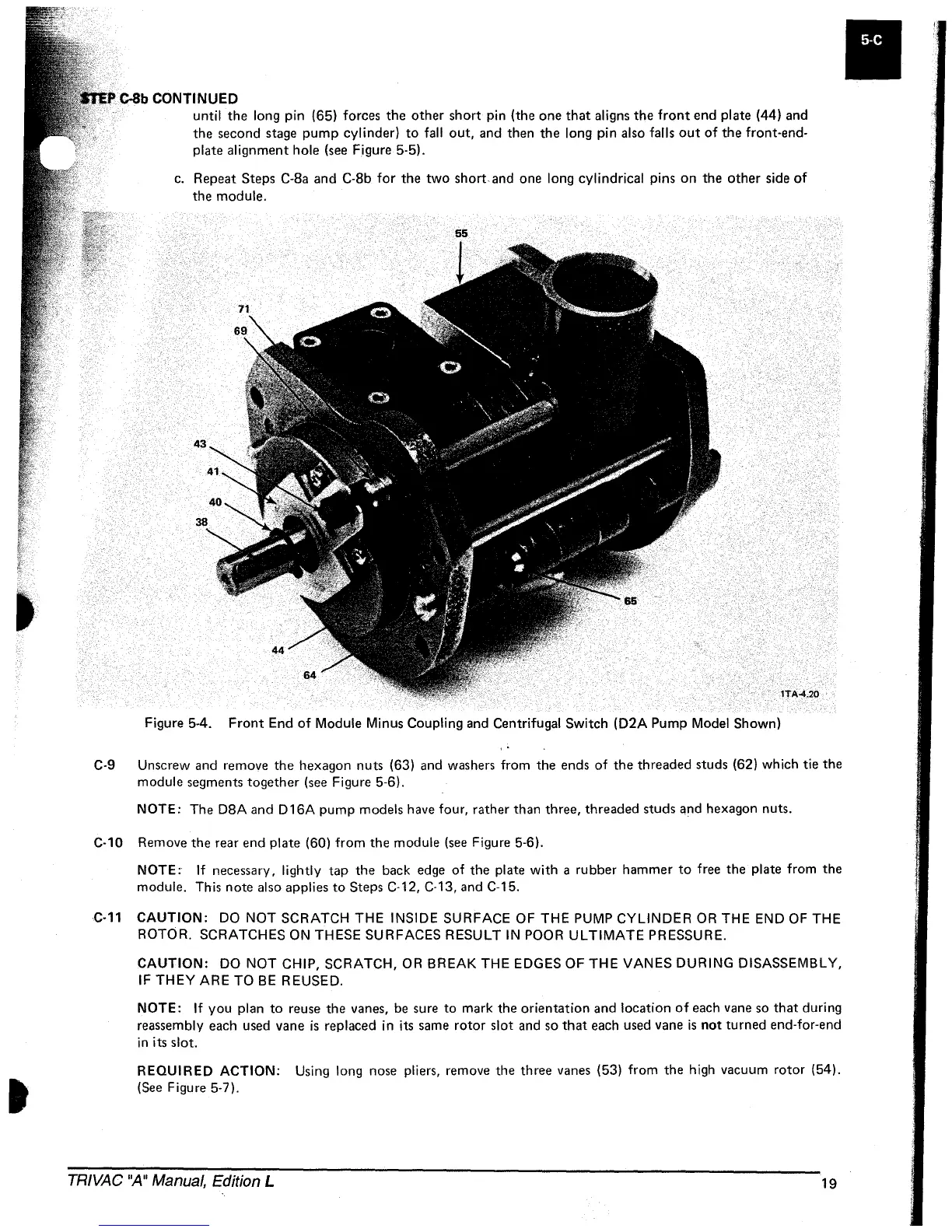

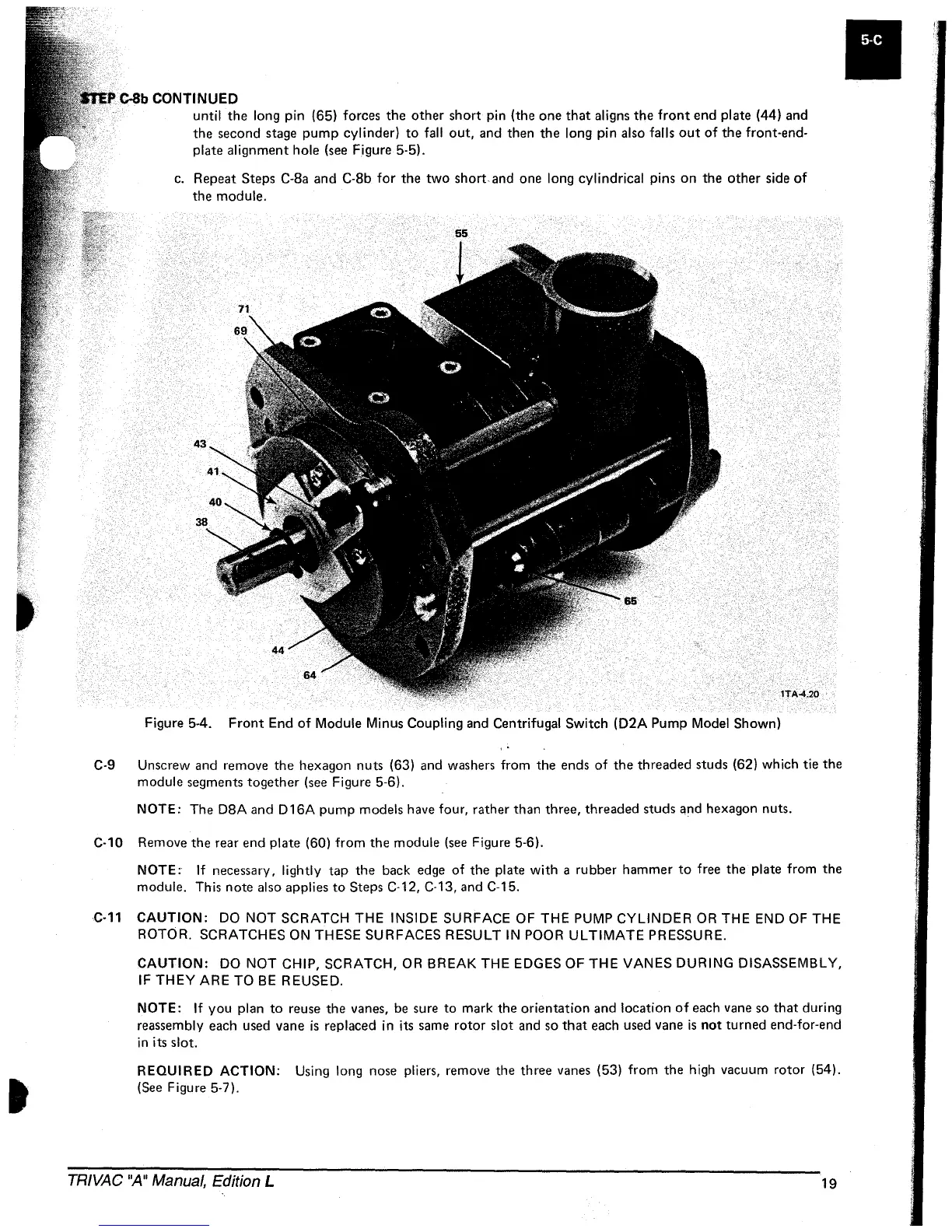

55

1TA-4.20

Figure 5-4.

Front

End

of

Module Minus Coupling and Centrifugal

Switch

(D2A

Pump

Model

Shown)

C-9 Unscrew

and

remove

the

hexagon

nuts

(63) and washers from

the

ends

of

the

threaded

studs

(62) which tie

the

module

segments

together

(see Figure 5-6).

NOTE:

The

D8A

and

0

16A

pump

models

have four,

rather

than

three,

threaded

studs

and

hexagon nuts.

C-10 Remove

the

rear

end

plate

(60)

from

the

module

(see Figure 5-6).

NOTE:

If

necessary, lightly

tap

the

back edge

of

the

plate

with

a

rubber

hammer

to

free

the

plate from

the

module. This

note

also applies

to

Steps

C-12, C-13, and C-15.

C-11 CAUTION:

DO

NOT

SCRATCH

THE

INSIDE

SURFACE

OF

THE PUMP CYLINDER OR THE END OF THE

ROTOR.

SCRATCHES

ON

THESE

SURFACES

RESULT

IN

POOR ULTIMATE PRESSURE.

CAUTION: DO

NOT

CHIP, SCRATCH, OR BREAK THE EDGES

OF

THE

VANES DURING DISASSEMBLY,

IF

THEY

ARE

TO

BE

REUSED.

NOTE:

If

you

plan

to

reuse

the

vanes, be sure

to

mark

the

orientation

and

location

of

each vane so

that

during

reassembly each used vane

is

replaced in its same

rotor

slot

and so

that

each used vane

is

not

turned

end-for-end

in

its slot.

REQUIRED

ACTION: Using long nose pliers, remove

the

three

vanes (53)

from

the

high vacuum

rotor

(54).

(See Figure 5-7).

TRIVAC

"A"

Manual, Edition L

19

Loading...

Loading...