1TA·3.t4

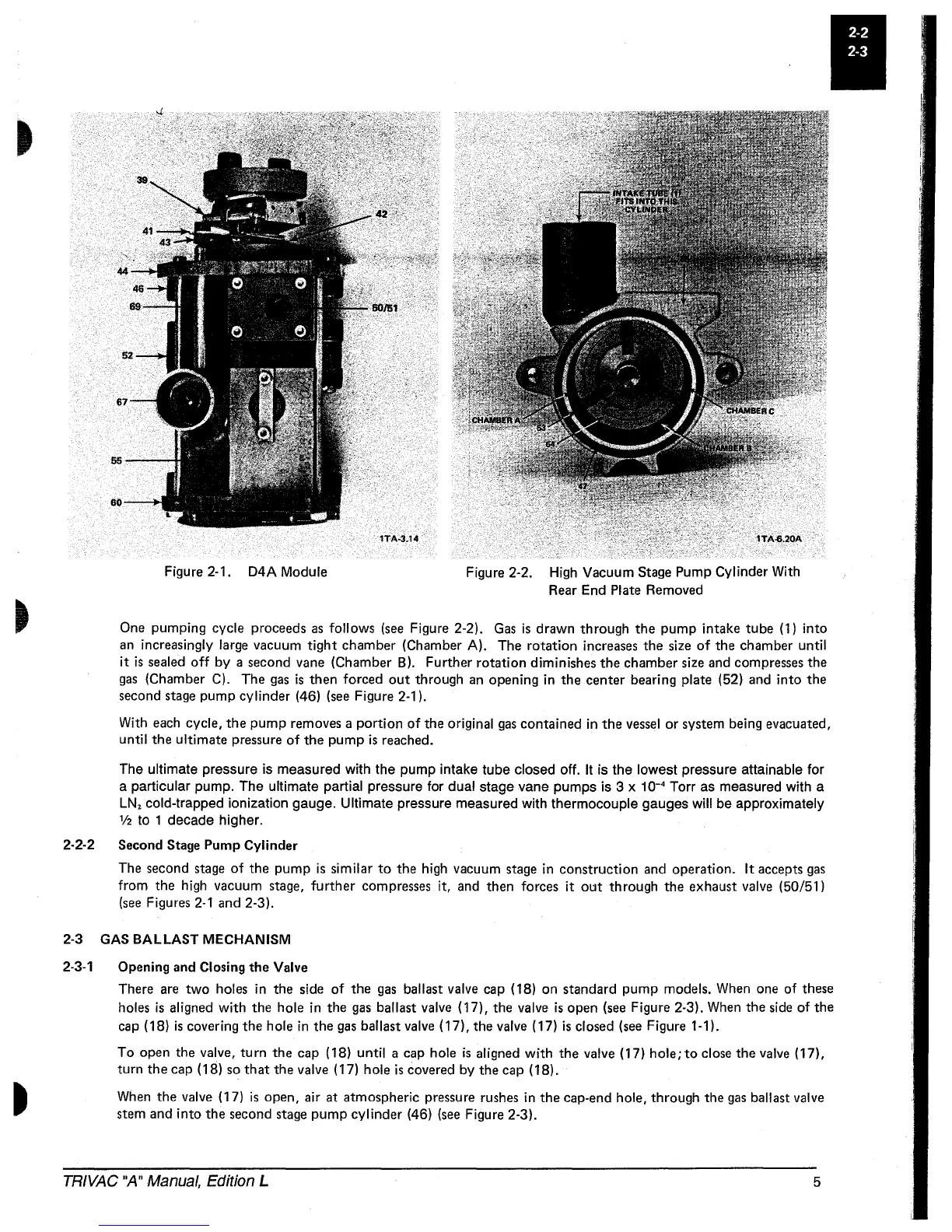

Figure 2·1.

D4A

Module

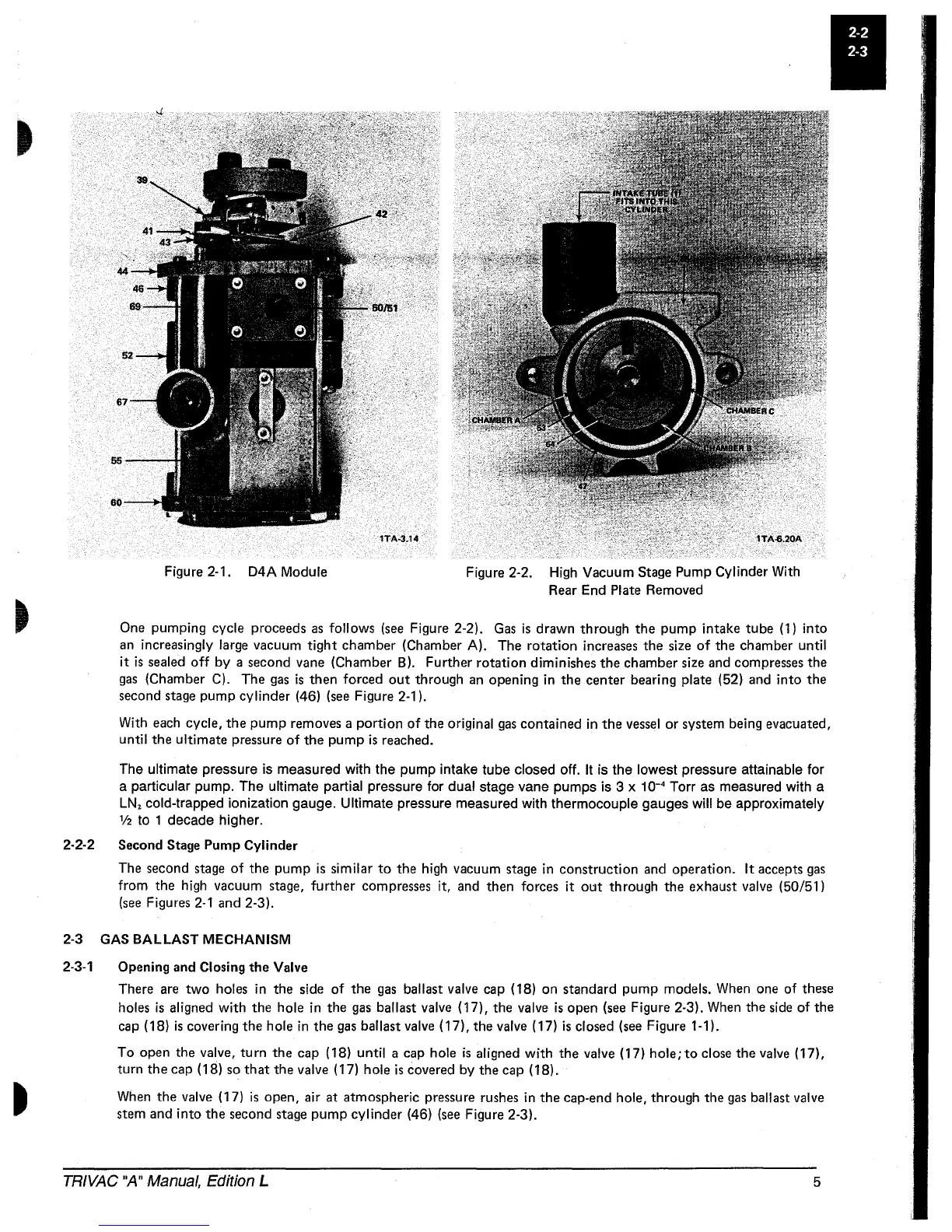

Figure 2·2. High Vacuum

Stage

Pump Cylinder With

Rear End

Plate Removed

One

pumping cycle proceeds

as

follows

(see

Figure 2-2).

Gas

is

drawn through the pump intake tube (1)

into

an

increasingly large vacuum

tight

chamber (Chamber A). The rotation increases the

size

of

the chamber

until

it

is

sealed

off

by

a second vane (Chamber B). Further rotation diminishes the chamber

size

and

compresses the

gas

(Chamber C). The

gas

is

then forced

out

through

an

opening in the center bearing plate (52)

and

into

the

second

stage

pump cylinder (46)

(see

Figure 2·1).

With

each

cycle, the

pump

removes a

portion

of

the original

gas

contained in the

vessel

or

system being evacuated,

until

the ultimate pressure

of

the pump

is

reached.

The

ultimate pressure is measured with the pump intake tube closed off. It is the lowest pressure attainable for

a

particular pump. The ultimate partial pressure for dual stage vane pumps is 3 x 10-

4

Torr as measured with a

LN

z

cold-trapped ionization gauge. Ultimate pressure measured with thermocouple gauges will be approximately

1/2

to 1 decade higher.

2-2·2 Second Stage Pump Cylinder

The second

stage

of

the pump

is

similar

to

the high vacuum

stage

in construction

and

operation.

It

accepts

gas

from the high vacuum

stage,

further

compresses

it,

and

then forces

it

out

through the exhaust valve (50/51)

(see

Figures

2-1

and 2·3).

2-3 GAS

BALLAST

MECHANISM

2-3-1

Opening and Closing

the

Valve

There

are

two

holes in the

side

of

the

gas

ballast valve

cap

(18) on standard pump models.

When

one

of

these

holes

is

aligned

with

the hole in the

gas

ballast valve (17), the valve

is

open

(see

Figure 2-3).

When

the

side

of

the

cap

(18)

is

covering the hole in the

gas

ballast

valve

(17), the valve (17)

is

closed

(see

Figure 1-1).

To open the valve,

turn

the cap (18)

until

a cap hole

is

aligned

with

the valve (17) hole;

to

close the

valve

(17),

turn the cap (18)

so

that

the valve (17) hole

is

covered by the cap (18).

When

the valve (17)

is

open, air at atmospheric pressure

rushes

in the cap-end hole, through the

gas

ballast valve

stem and

into

the second

stage

pump

cylinder (46)

(see

Figure 2-3).

TRIVAC "A" Manual, Edition L

5

Loading...

Loading...