"'"

"'"

It

§

()

=

!

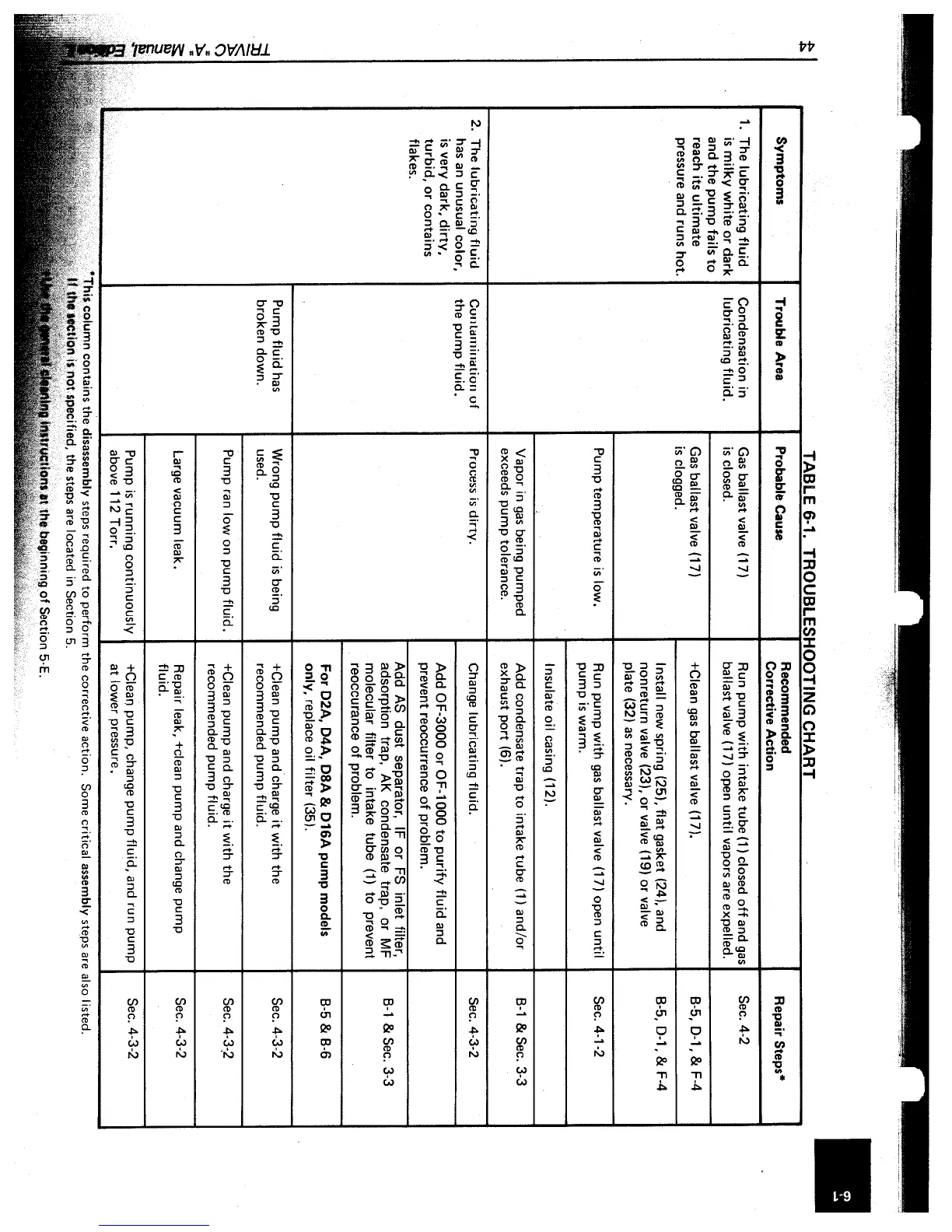

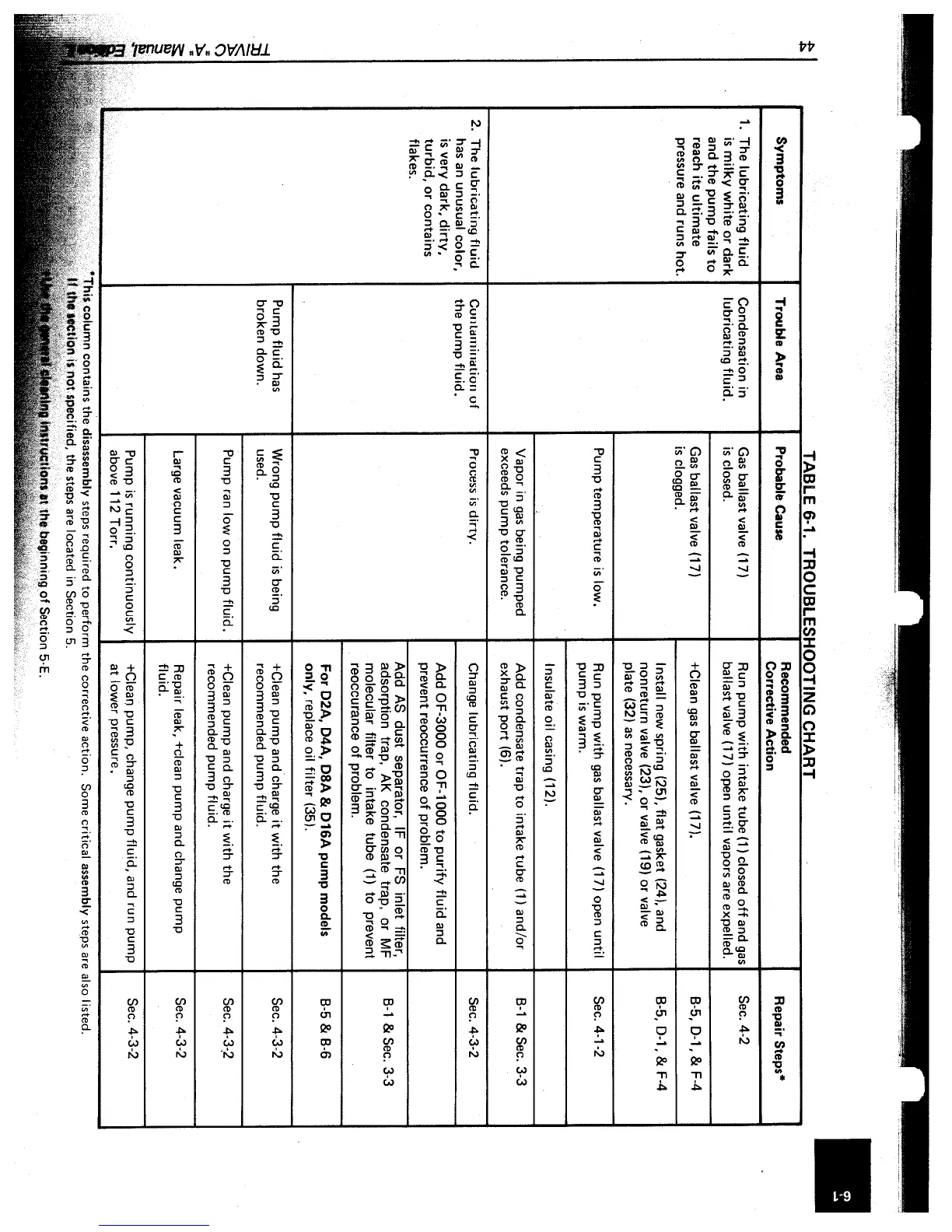

Symptoms

1. The lubricating

fluid

is

milky

white

or

dark

and the

pump

fails

to

reach its

ultimate

pressure and runs

hot.

2. The lubricating

fluid

has

an

unusual color,

is

very dark,

dirty,

turbid,

or

contains

flakes.

Trouble Area

Condensation in

lubricating

fluid.

Contamination

of

the pump

fluid.

Pump

fluid

has

broken down.

Probable

Cause

Gas

ballast valve (17)

is

closed.

Gas

ballast valve (17)

is

clogged.

Pump temperature

is

low.

Vapor in

gas

being pumped

exceeds

pump

tolerance.

Process

is

dirty.

Wrong

pump

fluid

is

being

used.

Pump

ran

low

on pump

fluid.

Large vacuum leak.

Pump

is

running continuously

above 112 Torr.

Recommended

Corrective

Action

Run pump

with

intake tube (1) closed

off

and

gas

ballast

valve

(17) open

until

vapors

are

expelled.

+Clean

gas

ballast valve (17).

Install new spring (25). flat gasket (24),

and

nonreturn

valve

(23).

or

valve

(19)

or

valve

plate (32)

as

necessary.

Run pump

with

gas

ballast valve (17) open until

pump

is

warm.

Insulate oil casing (12).

Add condensate trap

to

intake tube (1) and/or

exhaust

port

(6).

Change

lubricating

fluid.

Add

OF-3000

or

OF-lOOO

to

purify

fluid

and

prevent reoccurrence

of

problem.

or

adsorption trap, AK condensate trap, or

molecular filter to intake tube

(1)

to prevent

reoccurance of problem.

For

D2A. D4A.

D8A

&

D16A

pump

models

only,

replace oil

filter

(35).

+Clean pump

and

charge

it

with

the

recommended pump

fluid.

+Clean pump and charge

it

with

the

recommended pump

fluid.

Repair leak, +clean pump and change pump

fluid.

+Clear)

pump, change pump

fluid,

and run pump

at lower pressure.

Repair

Steps*

Sec.

4·2

B·5, 0-1,

& F-4

B-5, 0-1, & F-4

Sec.

4·1·2

B-1

&

Sec.

3-3

Sec.

4-3-2

B-1

&

Sec.

3·3

B-5

& B-6

Sec.

4-3·2

Sec.

4·3-.2

Sec.

4-3·2

Sec.

4-3-2

contains

the

disassembly steps required

to

perform

the

corrective action. Some critical assembly steps are also listed.

1$

not

specified,

the

steps are located

in

Section 5.

Loading...

Loading...