t

I

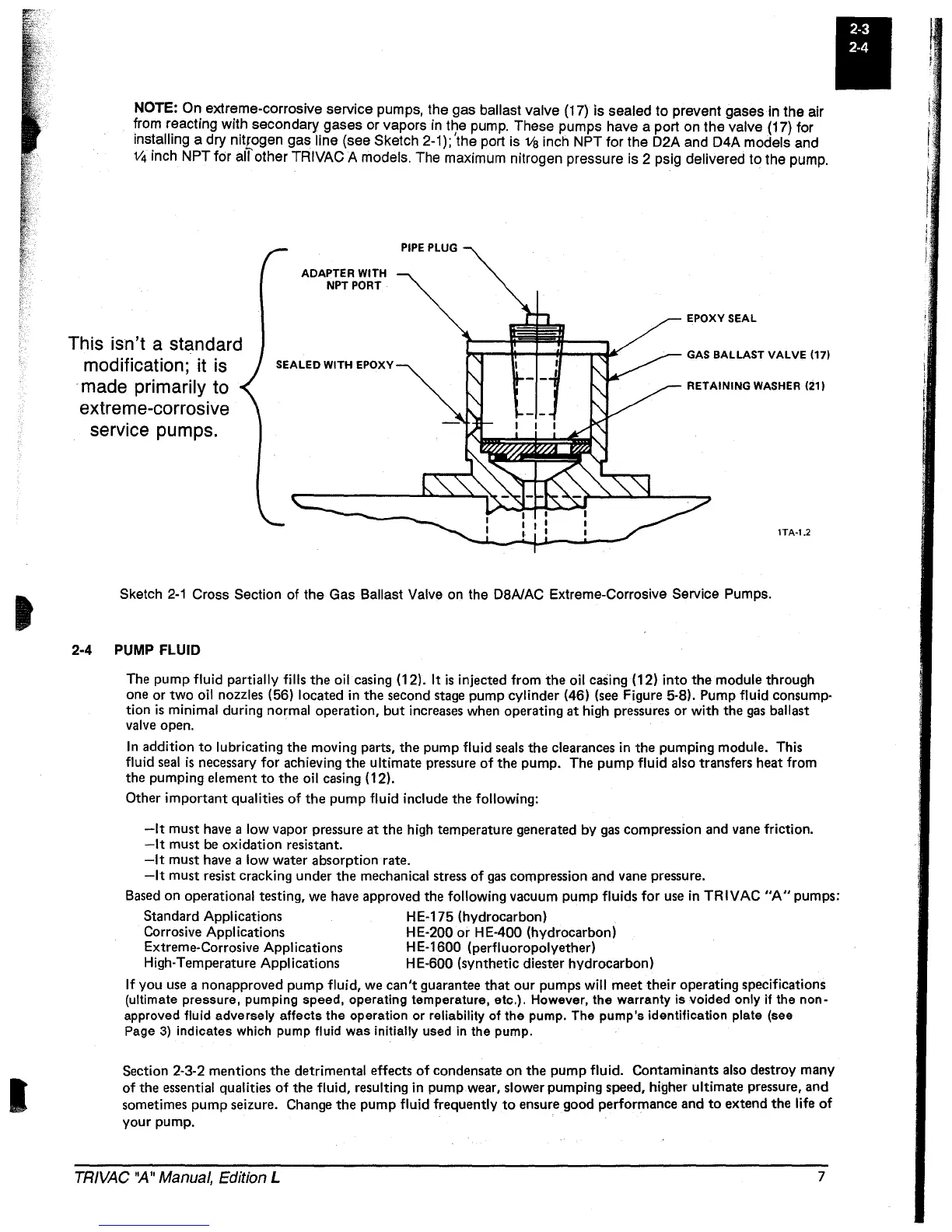

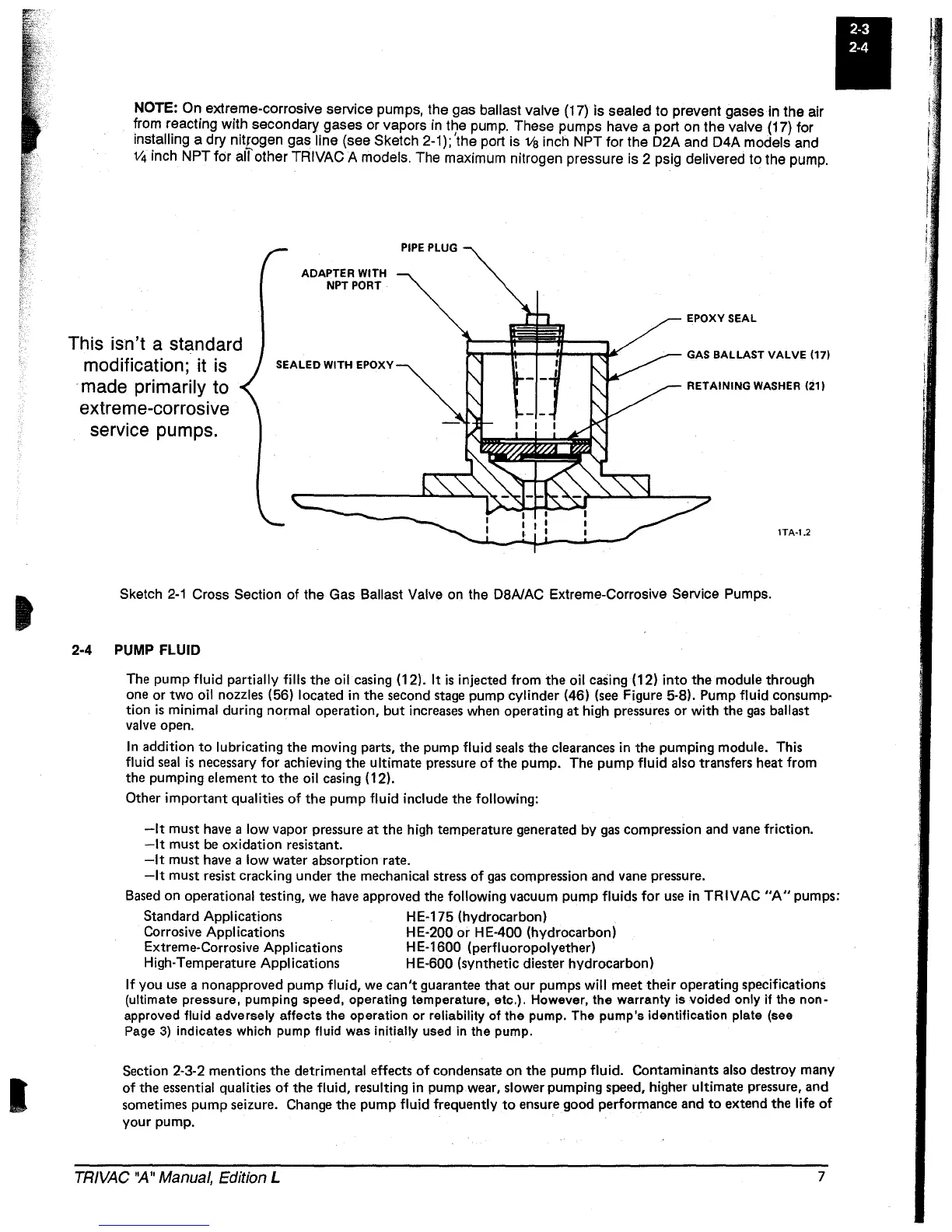

NOTE: On extreme-corrosive service pumps, the gas ballast valve (17) is sealed to prevent gases in the air

wit,h

secondary, gases or vapors in pump, These pumps have a port on

the

valve (17) for

Installing a dry nitrogen gas line (see Sketch 2-1); the port is

Va

inch NPT for the D2A and D4A models and

V4

inch NPT for

alT

other TRIVAC A models, The maximum nitrogen pressure is 2 psig delivered to the pump,

ADAPTER WITH

NPT PORT

EPOXY SEAL

This isn't a standard

modification; it

is

SEALED WITH EPOXY

GAS

BALLAST

VALVE

(17)

. made primarily to

extreme-corrosive

service pumps.

RETAINING WASHER (21)

2-4

lTA-1.2

Sketch

2-1

Cross Section of the Gas Ballast Valve on the DaAlAC Extreme-Corrosive Service Pumps.

PUMP FLUID

The

pump

fluid

partially fills the oil

casing

(12).

It

is

injected from the oil casing (12)

into

the module through

one

or

two

oil nozzles (56) located in the second

stage

pump cylinder (46)

(see

Figure 5-8). Pump

fluid

consump·

tion

is

minimal during normal operation,

but

increases

when operating at high

pressures

or

with

the

gas

ballast

valve

open.

In

addition

to

lubricating the moving parts, the pump

fluid

seals

the clearances in the pumping module. This

fluid

seal

is

necessary

for

achieving the ultimate

pressure

of

the pump. The pump

fluid

also

transfers heat from

the pumping element

to

the oil

casing

(12).

Other important qualities

of

the pump

fluid

include the following:

-It

must

have

a

low

vapor pressure at the high temperature generated by

gas

compression

and

vane

friction.

-It

must

be

oxidation resistant.

-It

must

have

a

low

water absorption rate.

-It

must resist cracking under the mechanical

stress

of

gas

compression and

vane

pressure.

Based

on operational testing,

we

have

approved the following vacuum pump fluids

for

use

in

TRIVAC

"A"

pumps:

Standard Applications HE-175 (hydrocarbon)

Corrosive Applications HE-200

or

HE-400 (hydrocarbon)

Extreme-Corrosive Applications H

E-1600 (perfluoropolyether)

High·Temperature Applications

HE-600 (synthetic diester hydrocarbon)

If

you

use

a nonapproved pump

fluid,

we

can't guarantee that our pumps

will

meet their operating specifications

(ultimate pressure, pumping speed, operating temperature, etc.). However,

the

warranty

is voided only if the non-

approved fluid adversely

affects

the operation or reliability

of

the

pump. The

pump's

identification plate (see

Page

3)

indicates which pump fluid was initially used in the pump.

Section 2-3-2 mentions the detrimental effects

of

condensate on the pump

fluid.

Contaminants

also

destroy many

of

the essential qualities

of

the

fluid,

resulting in pump wear, slower pumping speed, higher ultimate pressure, and

sometimes pump seizure.

Change

the pump

fluid

frequently

to

ensure good performance and

to

extend the life

of

your pump.

TRIVAC

''A"

Manual, Edition L

7

i

I

)

,

I'

Loading...

Loading...