Description

7

GA 01.600/10.02 - 07/01

By opening the gas ballast valve (2/1, optional) it is pos-

sible to admit a controlled quantity of air (gas ballast) into

the pump chamber while the compression process is in

progress. The gas ballast will prevent the condensation

of vapours within the pump up to the extent of the vapour

tolerance levels as stated in the specifications for the

pump (these data refer to water vapour).

A special lubrication system with forced lubrication of the

sliding bearings has been developed to enable operation

of the pump at intake pressures up to 1000 mbar.

An oil pump supplies the oil from the oil reservoir into a

high pressure oil system which in turn supplies all bea-

rings. From here the oil enters the pump chamber of the

vacuum pump.

The oil pump is located in bearing piece of the high vacu-

um stage. Separation of oil and gas in the pump involves

two stages. First an internal demister which is arranged

ahead of the exhaust valve ensures the creation of larger

droplets.

Next these are returned back to the oil reservoir via a

separation panel. This ensures a minimal loss of oil.

This and the combination with the large usable oil reser-

voir, results in long intervals between the oil exchanges,

even at high intake pressures.

The gas ballast valve (GB) is opened or closed by tur-

ning it (positions 0, 1, 2, 3).

Available as an option is a gas ballast valve having a

knurled screw (see Fig. 13 on page 28). When fully

opening this valve, the resulting gas flow will correspond

to that of valve position 3 in the following Table.

GB position Explanation

0 no gas ballast

maximum ultimate pressure

1 for cleaning the pump’s oil at a good ulti-

mate pressure and low oil consumption

2 good water vapour tolerance -

without producing excessive noise

3 maximum water vapour tolerance in

accordance with the technical data on

page 6.

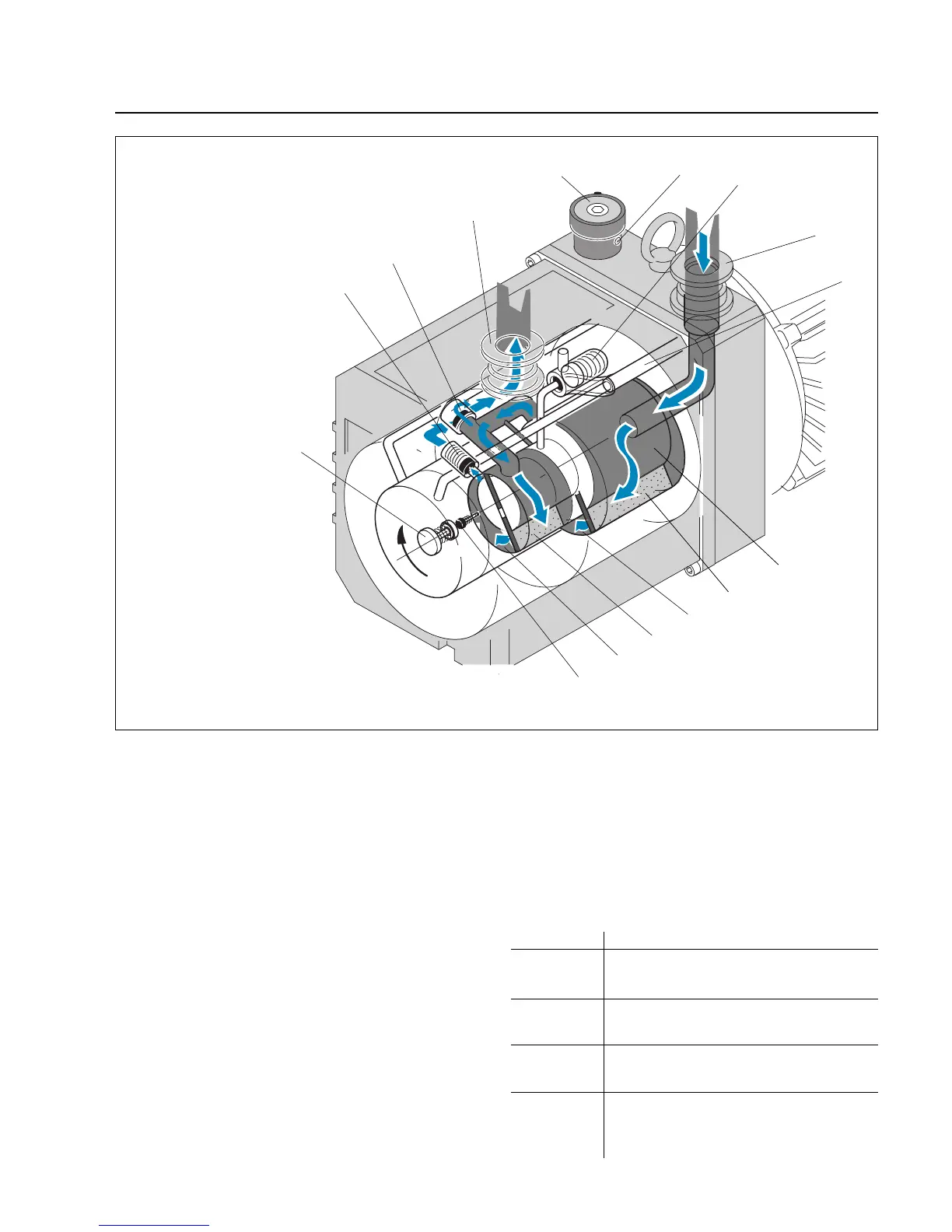

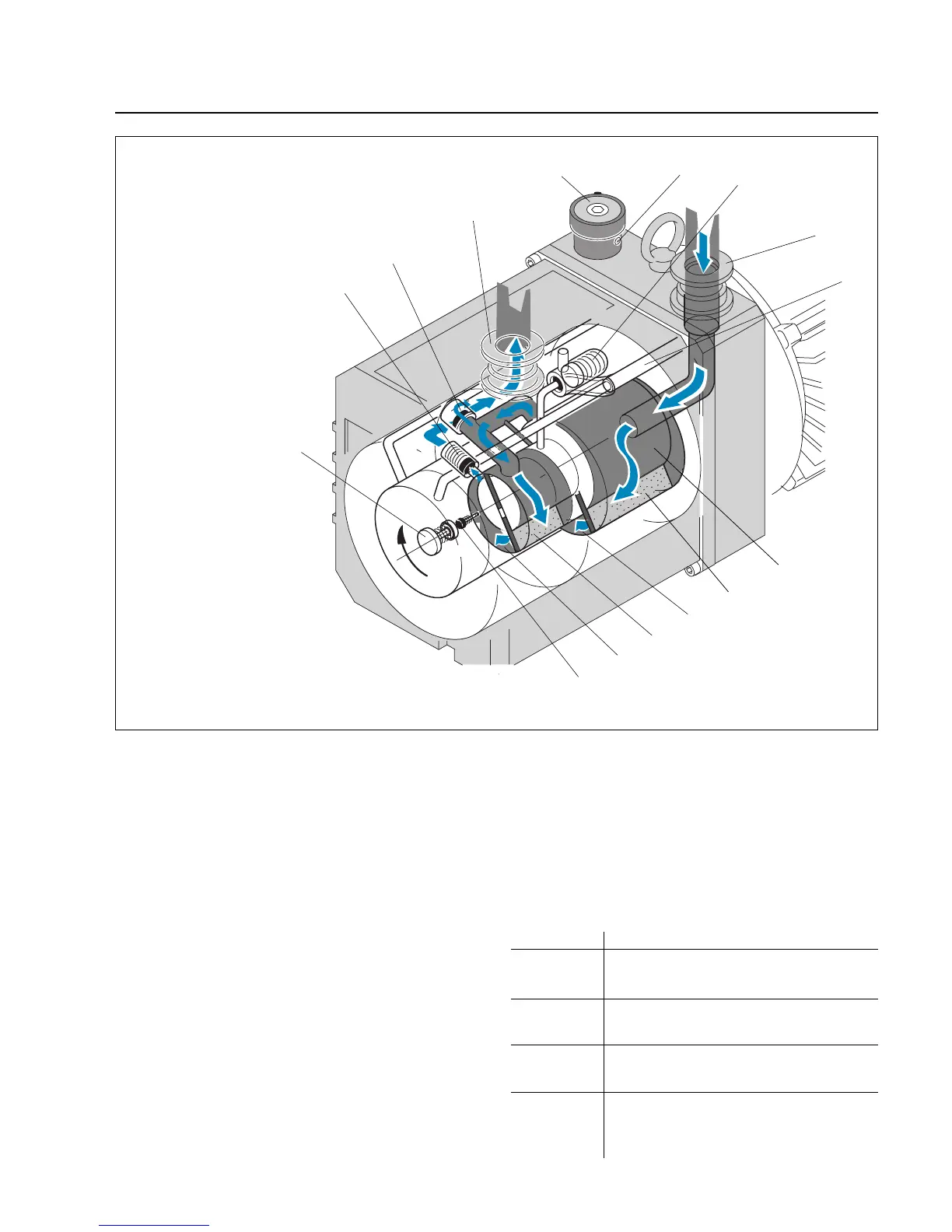

Key to Fig. 2

1 Gas ballast valve

2 Gas ballast inlet

3 Tandem valve

(vacuum protection)

4 Intake port

5 Oil feed (oil pump)

6 Rotor

7 Vane (HV)

8 High vacuum stage

(pump chamber)

9 Vane (FV)

10 Forevacuum stage

(pump chamber)

11 Non-return valve

12 Diaphragm valve

13 Exhaust valve

14 Bypass valve

15 Exhaust port

Fig. 2 Sectional view through a TRIVAC D 5 E pump

(other TRIVAC E models are similar)

Loading...

Loading...