91

Installation

Due to our policy of continuous product innovation, some specications may change without notication.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

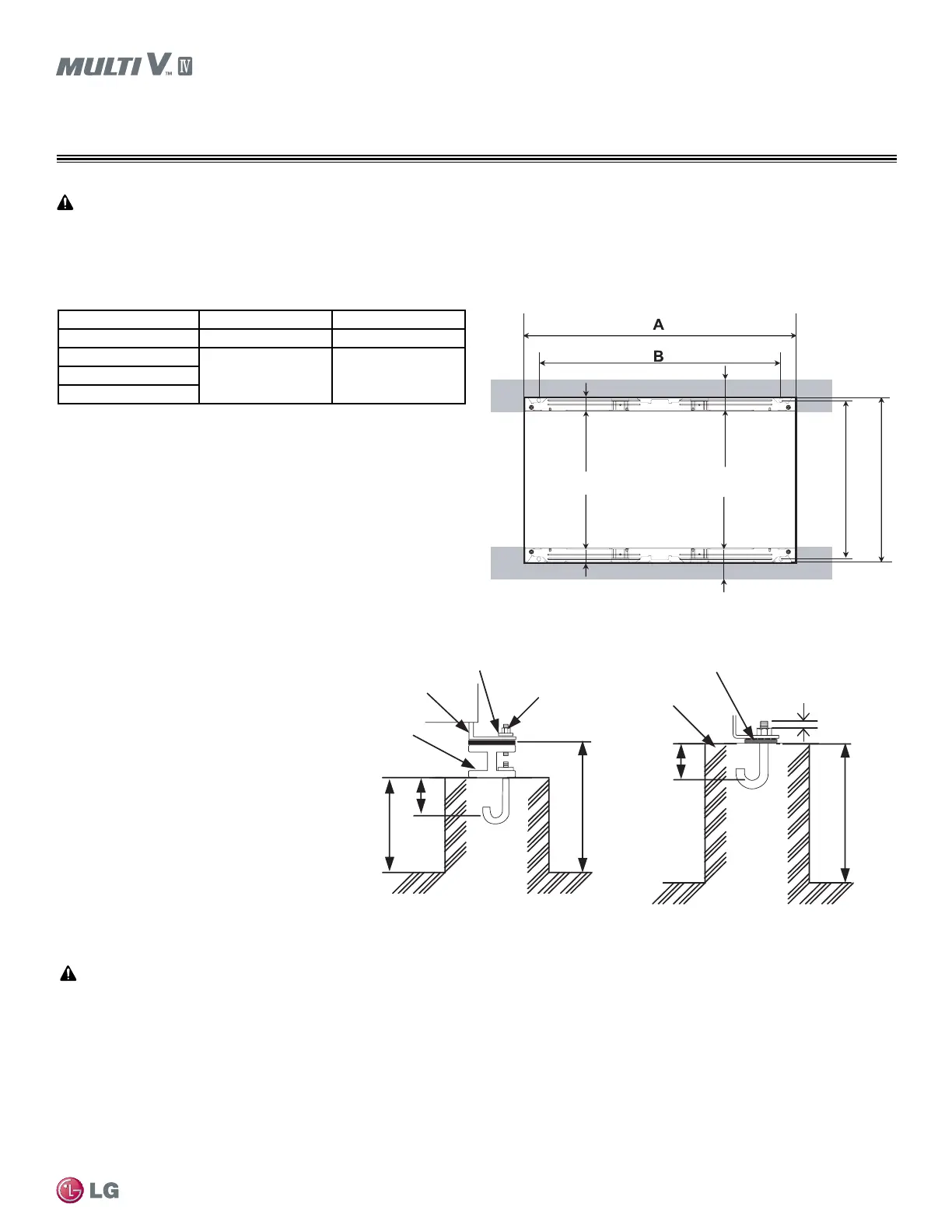

Figure 4: Close up of Anchor Bolts.

• Securely fasten all four (4) corners to the

supporting base.

• If not otherwise directed by the structural

engineer or local codes, Use a 7/8 inch or

1/2 inch diameter J-bolt. Use a hexagon nut

with a spring washer.

• Include anti-vibration material chosen by the

acoustics engineer.

• Include enough space for refrigerant piping

and electrical wiring when installing through

the bottom of the unit.

• Use an H-beam, concrete support, or other

acceptable support structure designed by a

structural engineer.

All referenced materials are to be eld-supplied as specied by the designer. Images are not to scale. Images are for reference only and are

not intended to be used for design purposes.

Note:

Mounting / Anchoring the Outdoor Unit

INSTALLATION

Unit: Inch

8

8

Nut

3

3

Spring Washer

Unit Mounting

Foot

Anti-vibration

Material

Four Bolts

Required

H-Beam

Concrete

Base

4

Three Threads

28-3/4

29-15/16

2-9/16

2-9/16

Unit: Inch

≥2-9/16≥2-9/16

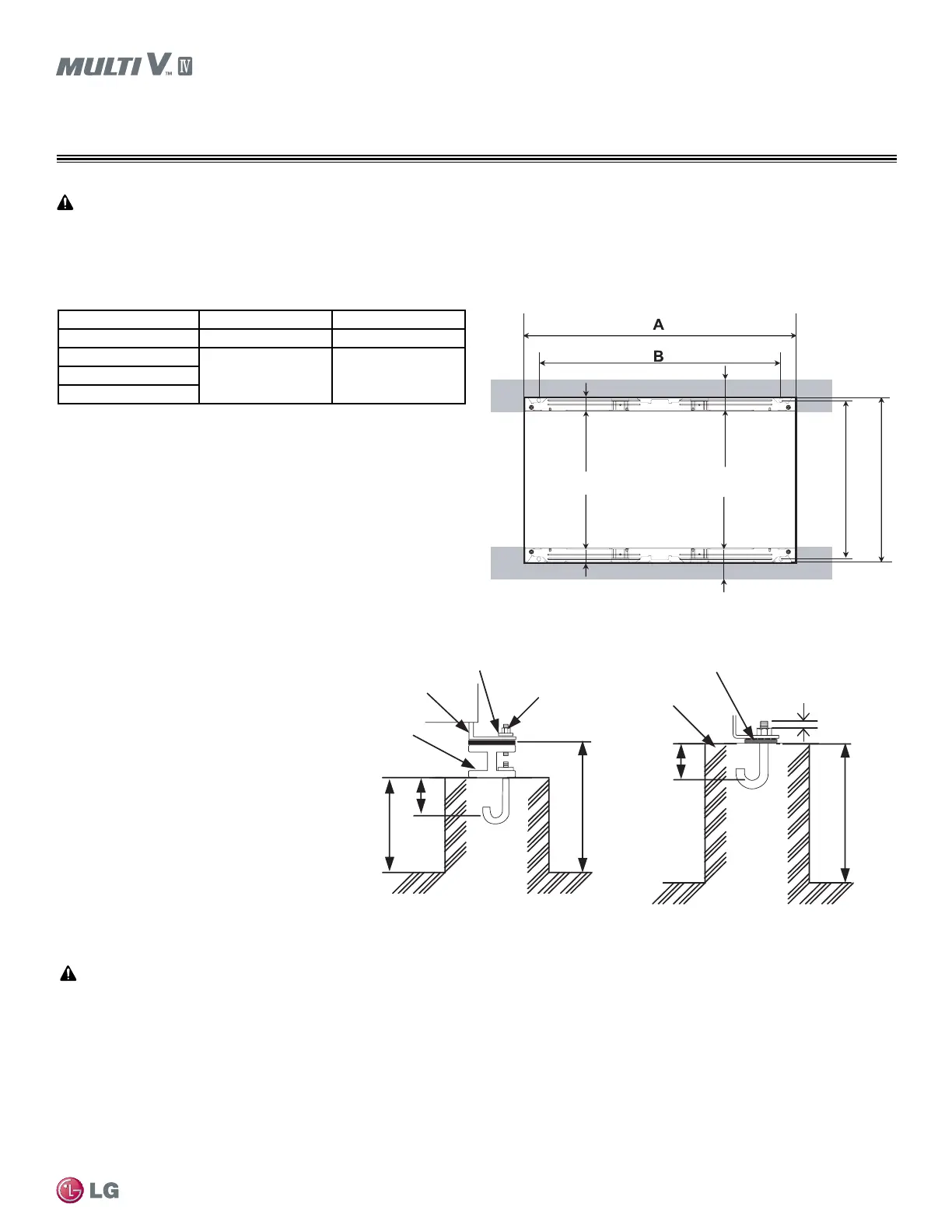

Figure 5: Location of the Anchor Bolts.

Capacity (ton) A (inches) B (inches)

6 36-1/4 31-3/16

8

48-13/16 43-3/810

12

Table 23: Anchor Bolt Location Specications.

Job site conditions may require routing utilities—including the refrigerant piping, condensate pipe, and electrical wiring—under the unit base.

If job site conditions warrant, consider adding mounting rails under the unit. The unit may need to be elevated above the oor to provide the

necessary slope for proper condensate draining on long pipe installations.

Loading...

Loading...