28

ENGLISH

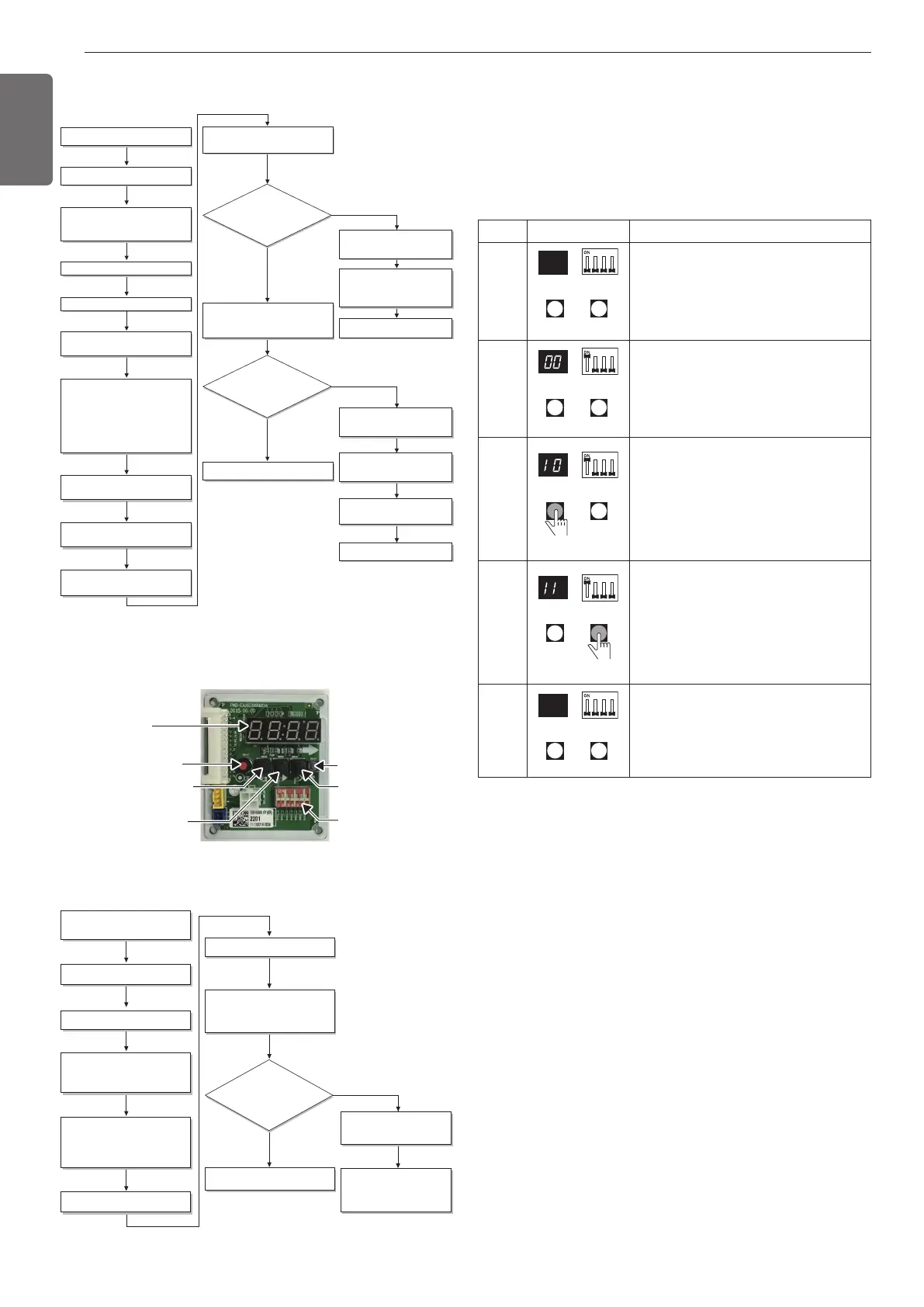

Flow chart of auto addressing for pipe detection

Completion of auto pipe detection

Are the number

of indoor units connected to the

outdoor unit wiring and displayed

one equal?

Reset the power of HR unit PCB

Confirm that the setting of No.2, 3 of

SW02E corresponds with the number of

indoor units.

Master unit PCB DIP switch on : No.5

Select the mode using ‘ȯ’, ‘ȭ’ Button :

“Idu” Push the ‘Ɨ’ button

Select the mode using ‘ȯ’, ‘ȭ’ Button :

“Idu” Push the ‘Ɨ’ button

Select the “Id 6” function using ‘ȯ’, ‘ȭ’

Button :“StA” Push the ‘Ɨ’ button

Select the “Id 5” function using ‘ȯ’, ‘ȭ’

Button :“Ath” or ”Atc” Push the ‘Ɨ’

button.

Outdoor temperature is over 15°C(59°F) :

“Ath” Using

Outdoor temperature is below 15°C(59°F) :

“Atc” Using

88' is displayed on 7-SEG of the outdoor

unit main PCB

Outdoor unit is operated for 5~60 minutes.

The number of indoor units detected is

displayed for 30 seconds on the outdoor

unit PCB after outdoor unit stopped

Display error on outdoor unit PCB

Display error on HR unit PCB

Outdoor unit PCB : HR

⇒

HR unit

number

⇒

Valve number

HR unit : '200'

Check the HR unit and indoor unit

Pipe detection error occur after 30

seconds.

Check the installation of pipe of

outdoor, indoor, HR unit

Incompletion of auto pipe detection

Retry auto pipe detection after

checking trouble

Is the pipe

setting condition

satisfied during the operation of

indoor unit?

Confirmation of indoor unit address setting

Turn No.1 of SW02E of HR unit PCB off.

NO

NO

YES

YES

※It is possible to be generated mode changing noise of heating and

cooling which is normal. There is no mode changing noise at normal

operation.

DIP-SWITCH

SW01D(reset)

SW04C(x:cancel)

7-Segment

SW03C(▶:forward)

SW02C(◀:backward)

SW01C(●:confirm)

Flow chart of manual addressing for pipe detection

Completion of manual pipe detection

Reset the power of HR unit PCB.

Enter the central control address into

each indoor unit using its wired remote

control.

On the HR unit PCB, manually set address

of each valve of the HR unit to the central

control address of the indoor unit

connected to the valve.

Reset the power of outdoor unit PCB.

Wait for about 5 minutes.

The number of the indoor units installed is

displayed.

Ex)HR

⇒

The number of the indoor

Check the central control address of

indoor and HR unit.

Make sure that reset the outdoor

unit power when changing the

central control unit

Are the number

of indoor units connected to the

outdoor unit and displayed one

equal?

Execute in case of Auto pipe detection

failure

Turn No.1 of SW02E of HR unit PCB on.

NO

YES

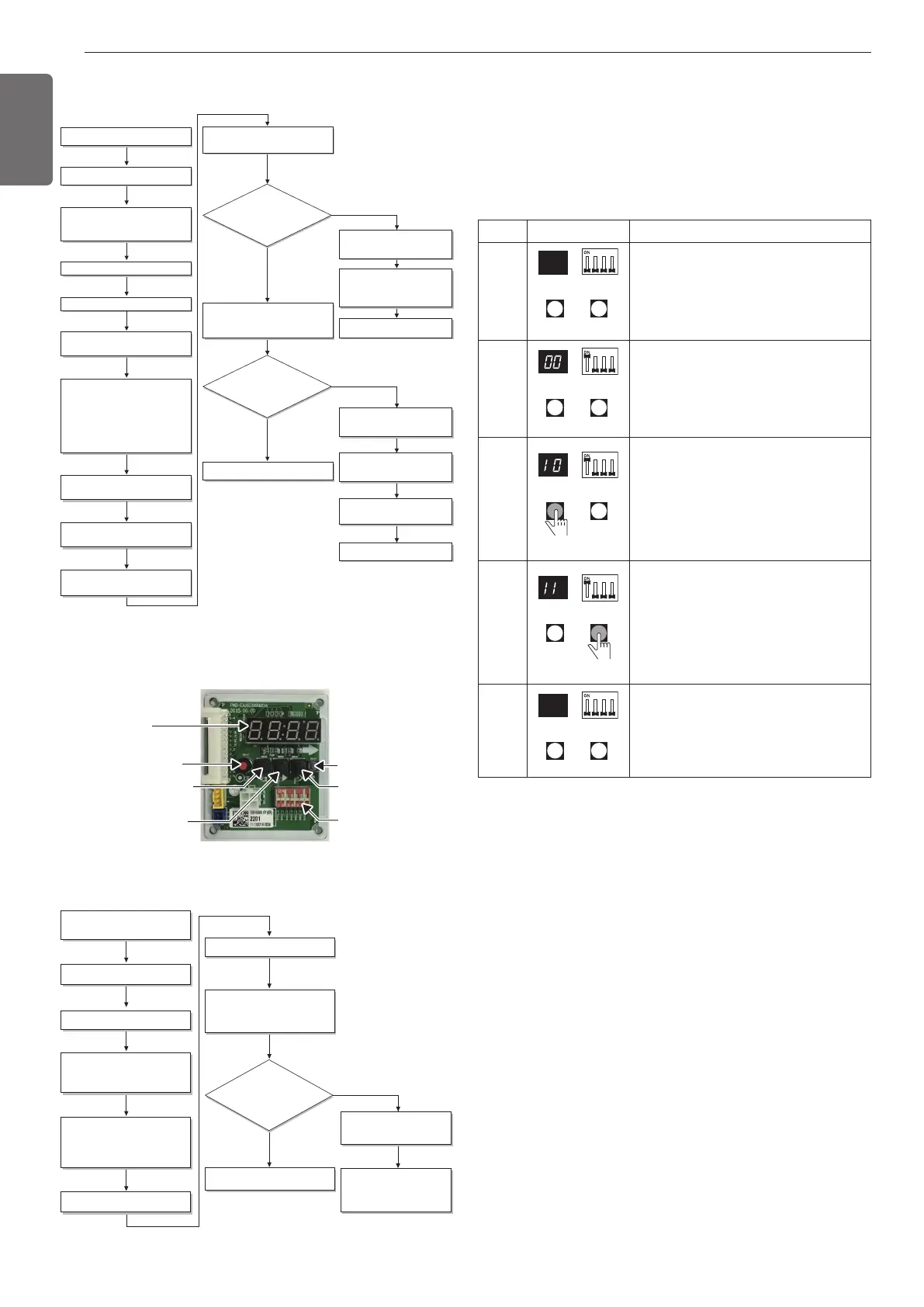

Example of manual valve addressing (Non-

Zoning setting)

(In case that an indoor unit of central control address "11" is connected

to a valve #1 of an HR unit)

- Prerequisite for manual valve addressing: central control address of

each indoor unit must be preset differently at its wired remote con-

trol.

- Above setup must be done for all HR unit valves.

- The valve that is not connected with any indoor unit should be ad-

dressed with any other number than used address numbers of the

valves connected with indoor units.

(The valves does not work if the address numbers are same.)

Example of manual valve addressing (Zoning

setting)

(In case that an indoor unit of central control address “11”, “12” is

connected to a valve #1 of an HR unit)

Zoning control is connecting 2 or more indoor units at one pipe of HR

unit. In case of Zoning control, in order to set controls with multiple in-

door units connection uses the rotary switch. Namely, only the rotary

switch changes from same valve set condition and set indoor units

connection.

1) On dip switch of the corresponding valves and sets the rotary

switch at 0.

2) Setting the number with tact switch.

3) In case of addition of indoor units to same port, increases 1 with the

rotary switch and sets number with tact switch.

4) In case of checking the number which the corresponding valve is

stored, turn on dip switch and set the number of rotary switch.

5) Indoor units set available 8 per a port(rotary switch 0~7), in case of

setting above of 8 with rotary switch, it will display error.

6) Setting the rotary switch on original condition(HR unit number set

conditions) after all finishing a piping setting.

No.Display and setup Setup and Contents

1

- Operation: None

- Display: None

2

- Operation: Turn dip S/W No.1 on to ad-

dress valve #1

- Display: Existing value saved in EEP-

ROM is displayed in

7-SEG.

3

- Operation: Set the digit of 10 to the

number in Group High data of the wired

remote control connected to the corre-

sponding indoor unit to the valve #1 by

pressing left tack S/W.

- Display: Digit increasing with the times

of pressing tack S/W is displayed in left

7-SEG

4

- Operation: Set the digit of 1 to the num-

ber in Group Low data of the wired re-

mote control connected to the

corresponding indoor unit to the valve

#1 by pressing right tack S/W.

- Display: Digit increasing with the times

of pressing tack S/W is displayed in right

7-SEG

5

- Operation: Turn dip S/W No.1 off to save

the address of

valve #1

- Display: "11" displayed in 7-SEG disap-

pears

1,MFL69717904,영영 18. 8. 29. 영영 2:50 Page 28

Loading...

Loading...