USER MANUAL - SS0407E / SS0507E / SS0607E / AS0607 / AS0607W / AS0607WE / AS0607E / AS0608 / AS0608E

43

Chapter 11 - Maintenance

Description

1) A report must be completed for each inspection.

2) Select the appropriate checklist according to the items checked.

3) Check the corresponding position after each inspection.

4) Learn how to perform the inspection step by step.

5) When the inspection result "N" is made, record it and stop operating the device until this is repaired and

rechecked. Place a check mark on the position "G" after the inspection.

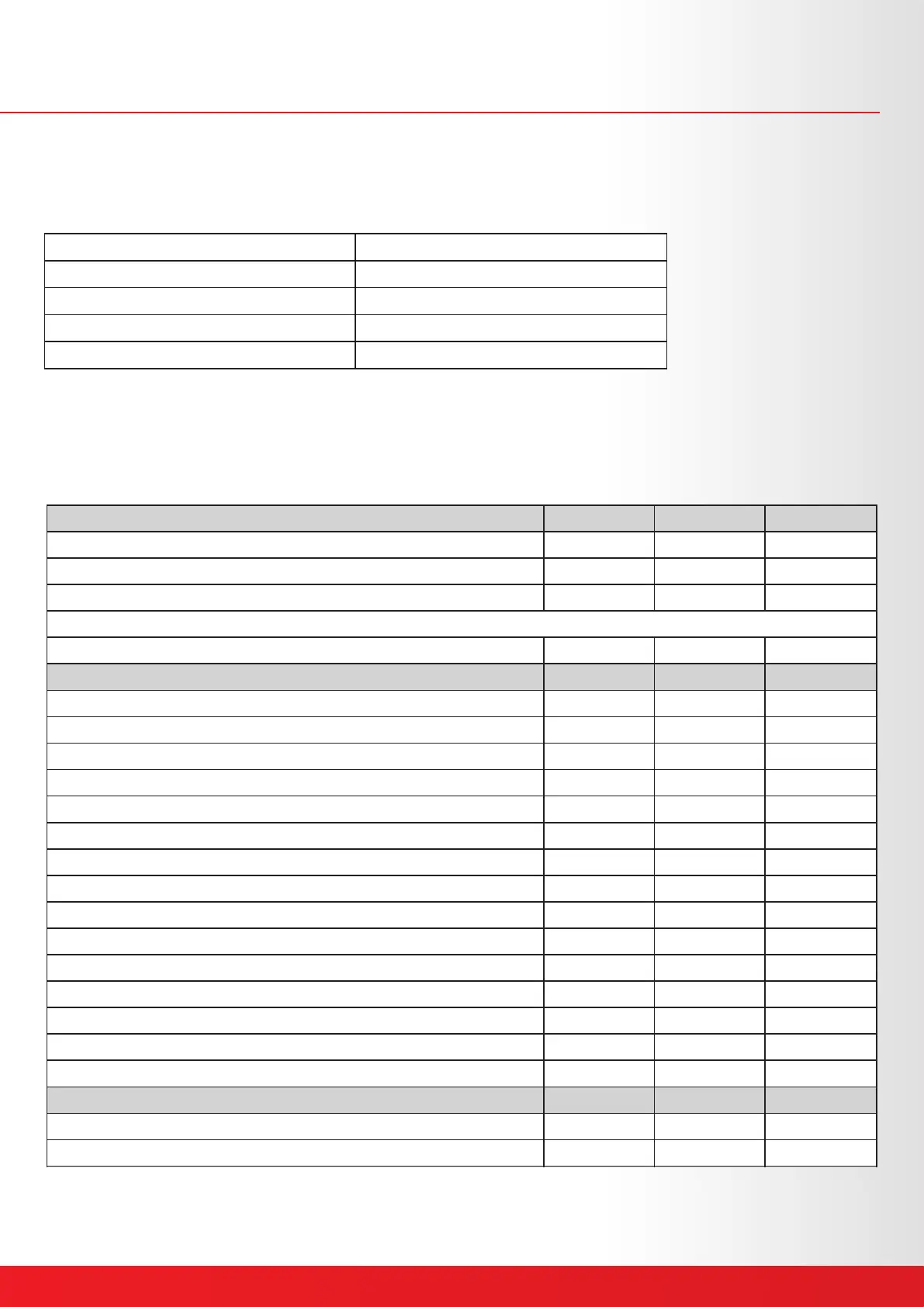

Every day or every 8 hours

Every quarter or every 250 hours

Every six months or every 500 hours

Every year or every 1000 hours

Every two years or every 2000 hours

A

A + B

A + B + C

A + B + C + D

A + B +C + D + E

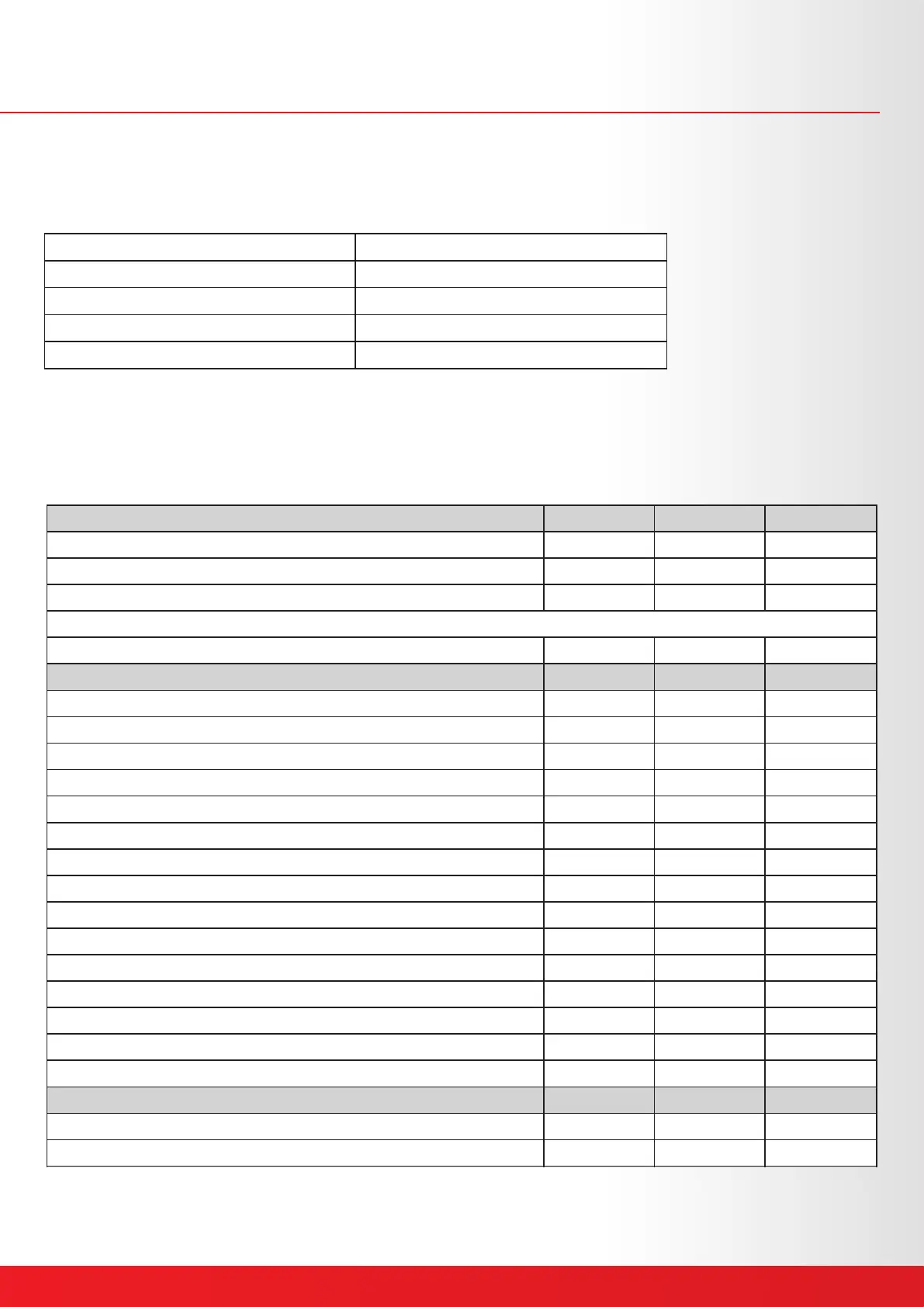

Checklist A (V) Completed

(N) not completed

(G) repaired

A-1 Inspection manual and label

A-2 Inspection for operation

A-3 Functional Test

40 hours later

A-4 maintenance of 30 days

Checklist B

B-1 Battery

B-2 Cable

B-3 Tyre and rim

B-4 Emergency stop

B-5 Key switch

B-6 Klaxon

B-7 Disc brake

B-8 Driving speed in retracted status

B-9 Driving speed in lifting status

B-10 Driving at low speed

B-11 Hydraulic oil analysis

B-12 Exhaust system

B-13 Tray component chassis

B-14 Test of lower limit and hollow protective switch

B-15 Test of upper limit switch

Checklist C

C-1 Platform overload system

C-2 Replacing the outlet valve of the hydraulic oil tank

Checklist D

D-1 Inspection for wear-resistant disc block of scissors

D-2 Replacement of hydraulic oil filter core

Checklist E

E-1 Hydraulic Oil

(V) Completed

(N) not completed

(G) repaired

(V) Completed

(N) not completed

(G) repaired

(V) Completed

(N) not completed

(G) repaired

(V) Completed

(N) not completed

(G) repaired

Loading...

Loading...