www.lgmgeurope.com

AS0808 / AS0808E / AS0812 / AS0812E / AS1012 / AS1012E / AS1212 / AS1212E / AS1413

44

Chapter 11 - Maintenance

11.9 Steps from checklist A

A-1Inspection Manual and label

The completeness of the operation and maintenance manual is the basis for safe operation. Every device comes with

a manual that is stored in a box on the platform. An unreadable or incomplete manual does not provide sufcient

information for safe operation.

Also make sure that all safety labels remain in good condition. The label can indicate the possible operating risks of

the machine for the operator. It also displays operating and maintenance information for the user. The illegible labels

no longer display the warnings and therefore a dangerous working environment can arise.

1) Check and make sure that the operation and maintenance manual is kept in the maintenance box.

2) Check the manual for clear notes and completeness.

Result: The manual corresponds to the model and all the notes in the manual are clear and complete.

Result: The manual does not correspond to the model and the notes in the manual is illegible and incomplete.

Stop working with the machine before replacing the manual.

3) Check the label control schedule and carefully check whether the label is illegible or complete.

Result: All labels are complete, legible and intact. Result: The labels are missing, illegible or incomplete.

Stop working with the machine before replacing the label.

4) After use, return the manual to its original position.

Reminder: Contact LGMG if necessary to replace manual or label.

A-2Inspection for operation

The inspection for operation is essential for the safe operation of the machine. The inspection for operation is made in

the form of a visual inspection before operating the machine. The inspection is used to detect signicant problems of

the machine for the functional test and to determine whether routine maintenance procedures are necessary.

For all inspection procedures, see "Inspection for Operation" in this manual.

A-3Function test

The function test is essential for the safe operation of the machine. The functional test is aimed at detecting the func-

tional defects of the machine before operation. The defective machine cannot be put into operation. Once any func-

tional defects have been found, mark the machine immediately and do not continue to use it.

For all inspection procedures, see "Function test" in this manual.

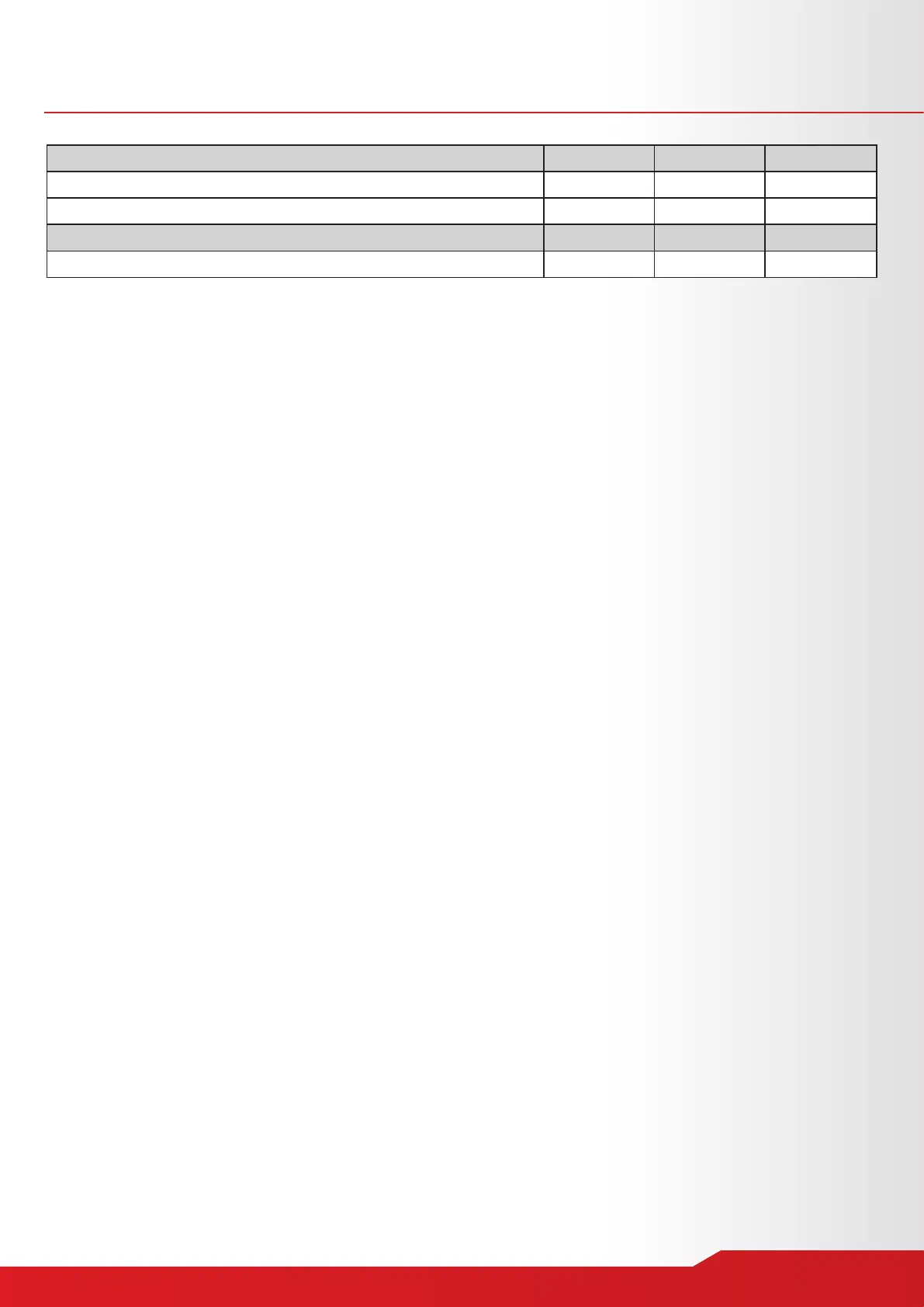

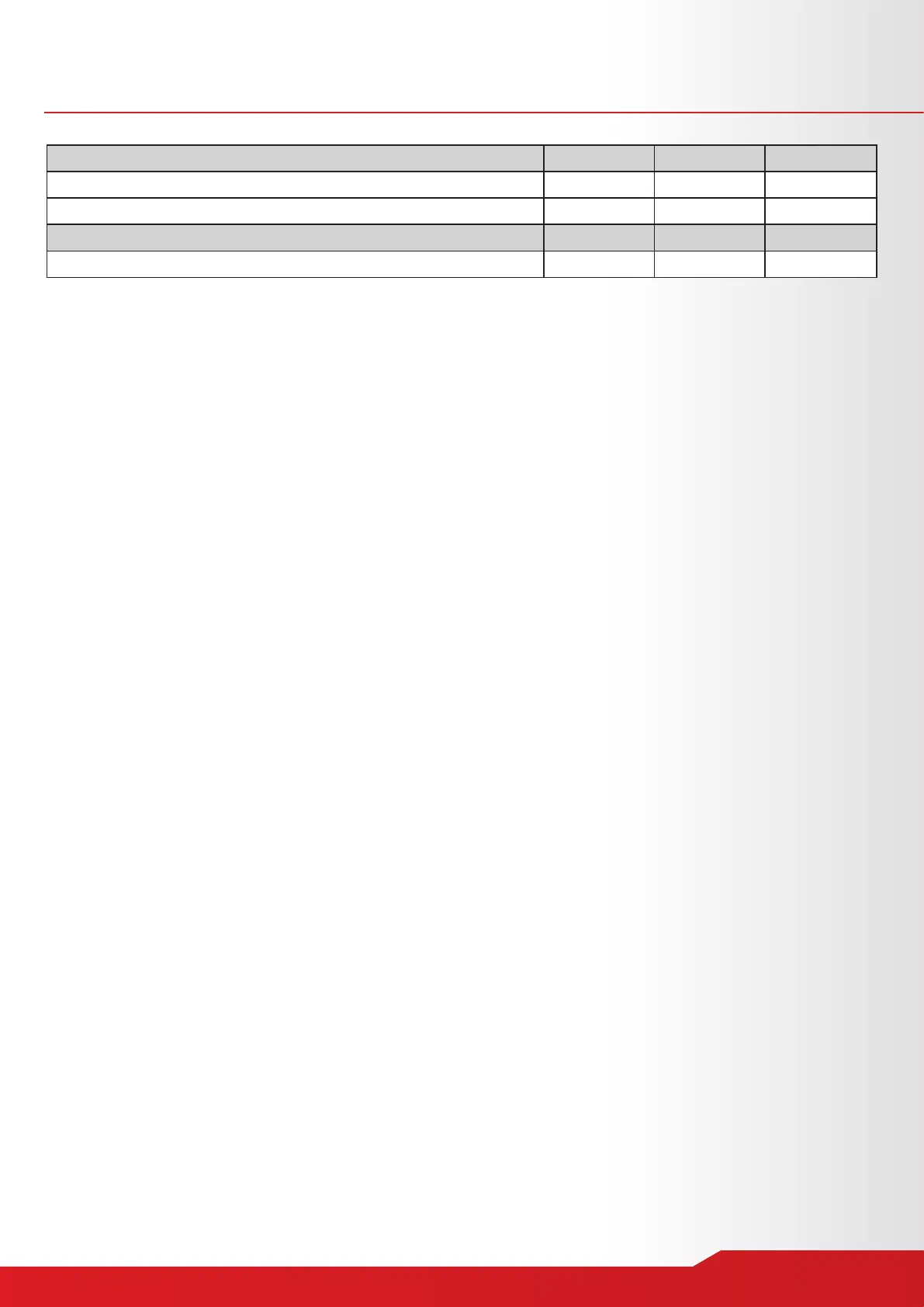

Checklist A (V) Completed

(N) not completed

(G) repaired

A-1 Inspection manual and label

A-2 Inspection for operation

A-3 Functional Test

40 hours later

A-4 maintenance of 30 days

Checklist B

B-1 Battery

B-2 Cable

B-3 Tyre and rim

B-4 Emergency stop

B-5 Key switch

B-6 Klaxon

B-7 Disc brake

B-8 Driving speed in retracted status

B-9 Driving speed in lifting status

B-10 Driving at low speed

B-11 Hydraulic oil analysis

B-12 Exhaust system

B-13 Tray component chassis

B-14 Test of lower limit and hollow protective switch

B-15 Test of upper limit switch

Checklist C

C-1 Platform overload system

C-2 Replacing the outlet valve of the hydraulic oil tank

Checklist D

D-1 Inspection for wear-resistant disc block of scissors

D-2 Replacement of hydraulic oil filter core

Checklist E

E-1 Hydraulic Oil

(V) Completed

(N) not completed

(G) repaired

(V) Completed

(N) not completed

(G) repaired

(V) Completed

(N) not completed

(G) repaired

(V) Completed

(N) not completed

(G) repaired

Loading...

Loading...