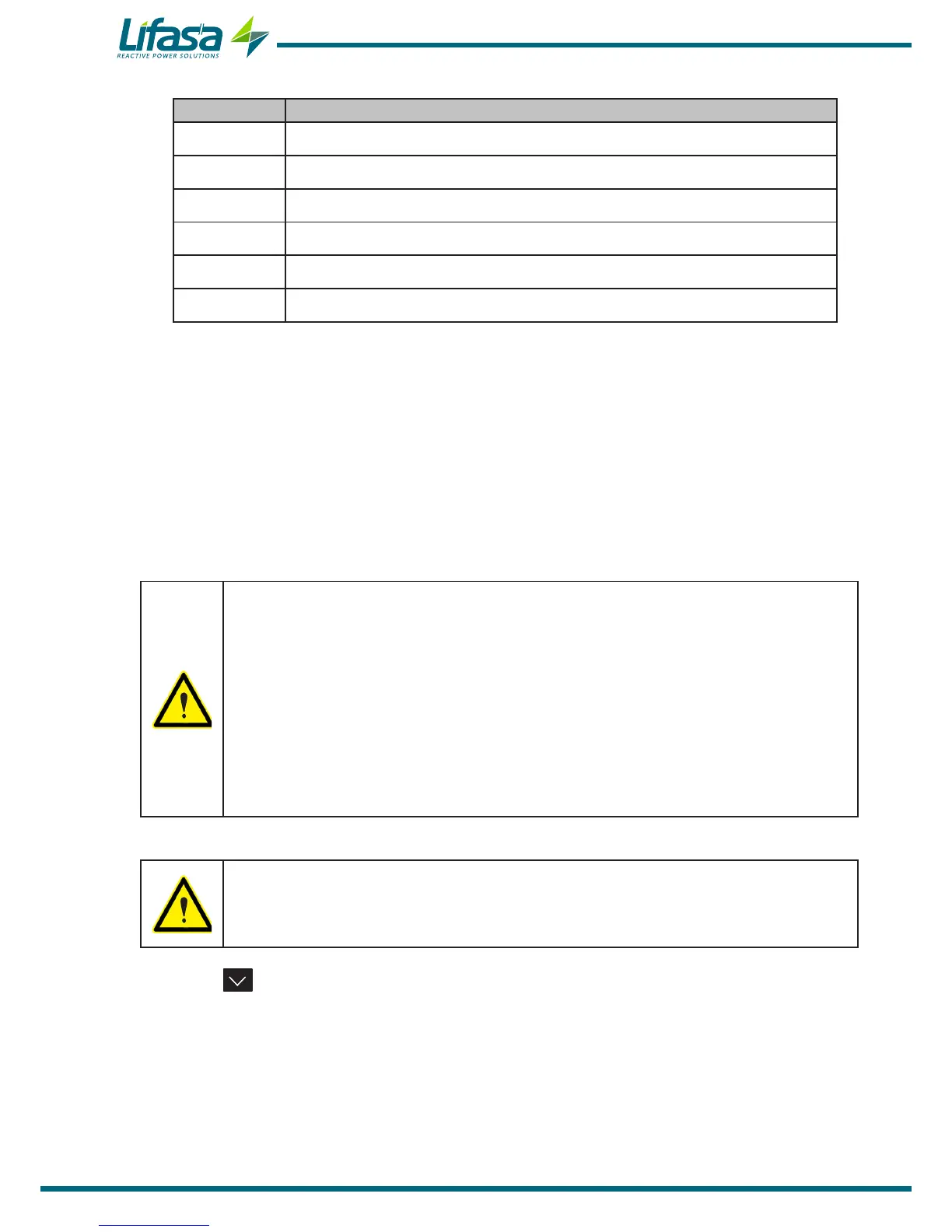

Table 40 (Continuation): Code of Plug&Play errors�

Code Description

P04

Error in the measurement of the largest capacitor.

P05

No capacitors found.

P06

Incorrect measurement of the number of capacitors.

P07

Incorrect measurement of the ratio of the rst capacitor.

P08

Possible error in the program calculated.

P09

C/K out of range.

In the case of the P00 error, i.e., when capacitors have been deactivated by a leakage current

alarm or forced in the On/Off/Auto Conguration, the P&P function will not be started until the

problem is resolved.

The Plug&Play function is designed to assist with the installation of the reactive energy

compensation system, with the initial conguration of the regulator or when there are changes

in the system (new regulator, new cabling, new stage, etc.). For this reason, it is necessary

prior to the Plug&Play function to solve the possible problems with faulty capacitors by means

of maintenance or replacement, as well as to congure all the stages in Auto mode, as they

come by default.

Conditions for the correct operation of the Plug&Play function:

The system should be maintained with an inductive cosine of 0.62 to 0.99

throughout the process.

The power in the system should be stable. Any major load changes (>10 %

in less than 20 seconds) would result in an incorrect calculation of the capacitor

power ratings.

There must be enough current in the system, above 100 mA AC at the

regulator intake.

If the load is unbalanced, the correct operation of the Plug&Play function will

depend on the phase to which the current transformer is connected.

I

Once the Plug&Play function is nished, the primary of the current transformer

needs to be congured in order for the unit to measure the current and the

powers correctly.

Press the key to move on to the next conguration point.

If no keys are pressed for 5 minutes, the unit switches to the simulation screen, “5.27.-

SIMULATION SCREEN”.

74

Loading...

Loading...