Do you have a question about the Lincoln Electric CLASSIC III SVM 137-A and is the answer not in the manual?

| Brand | Lincoln Electric |

|---|---|

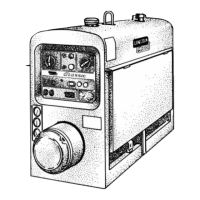

| Model | CLASSIC III SVM 137-A |

| Category | Welding System |

| Language | English |

Essential operating steps, safety, and a general description of the machine.

Location and function of all controls, including current adjustment.

Specific controls and procedures for operating the gasoline engine.

Specific controls and procedures for operating the diesel engine.

How to perform welding and utilize auxiliary power output.

Routine maintenance for the engine, including oil, filters, and cooling.

Instructions for effectively using the troubleshooting guide.

Troubleshooting steps for zero or low welding and auxiliary output.

Troubleshooting engine idle, speed, and starting problems.

Troubleshooting loud arc, excessive spatter, or arc pop-outs.

Detailed tests and replacement steps for alternator, field windings, and solenoids.

Adjusting engine speed and understanding output waveforms.

Loading...

Loading...