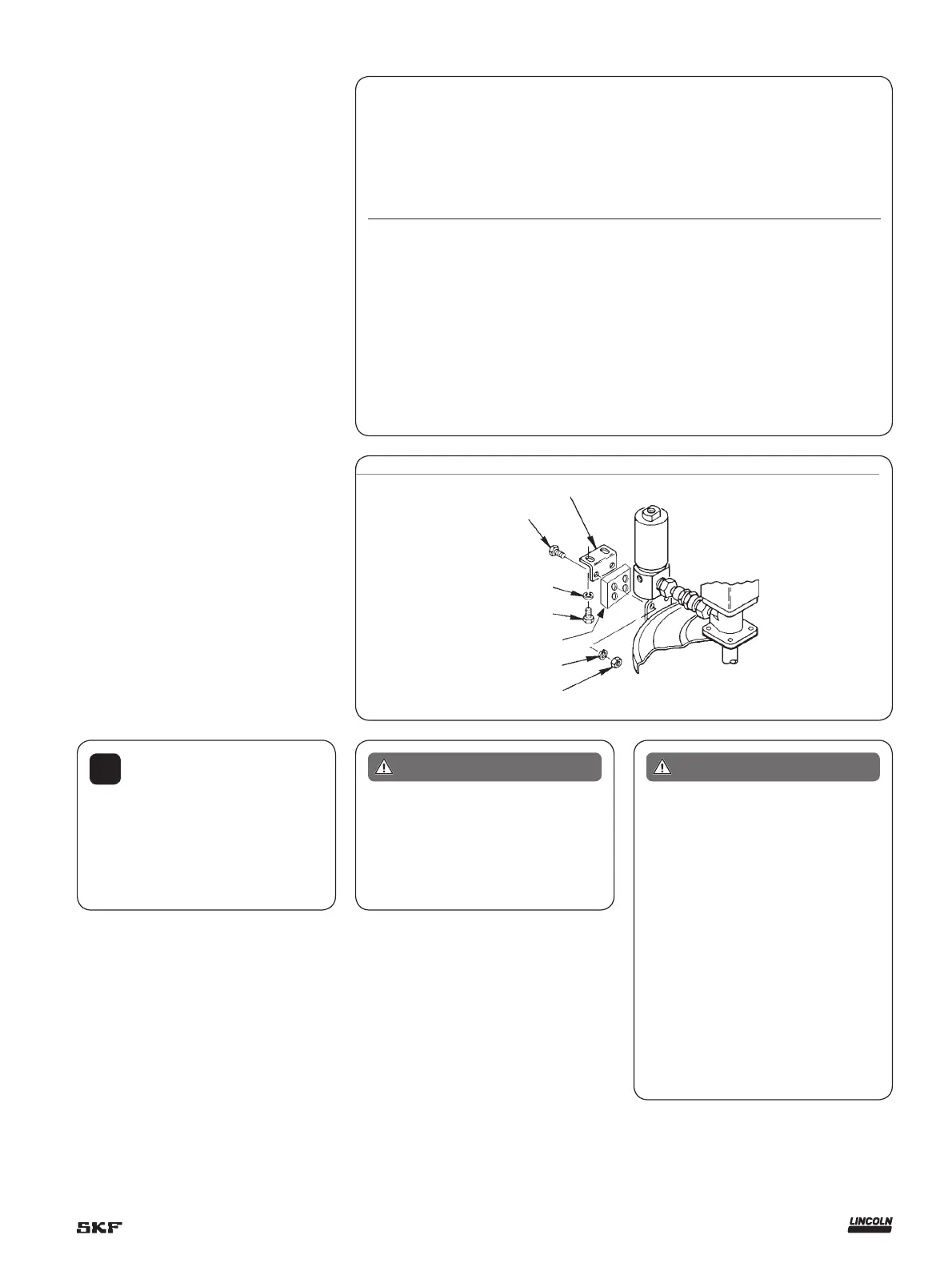

Fig. 4

Installing the pump

Typical installation is shown only as a guide

for selecting and installing system compo-

nents. Contact your Lincoln

Industrial representative for assistance

in designing a system to suit your spe-

cic needs.

The pump was tested in lightweight oil

which was left in to protect the pump from

corrosion. Flush the pump before connect-

ing it to the system to prevent contamina-

tion of the grease with residual oil.

The pump has flow and pressure controls

integrated into the manifold (76). A normally

closed on/off Solenoid Valve (74) is also in-

tegrated into the manifold and will start or

stop the pump operation.

1 Mount the pump securely on the drum

cover so that it cannot move or vibrate

during operation.

2 Attach hydraulic supply line to the Inlet

and return line to the tank ports.

3 Connect material supply line to the pump

outlet. Plug the unused outlet on opposite

side of the pump.

4 Install high pressure shut-off valve in the

material supply line (required)

5 Connect 24 V DC power supply to the

solenoid valve (74) († fig. 1).

Use connector plug (75) supplied with the

pump.

!

Notice

To install the pump model 85481

as a replacement pump for 84961 used

on model 84944, use adapter/spacer kit

P/N 272013 with bolts P/N 50014,

included in the pump package († fig. 4).

Hydraulic pump performance specifications

Test conducted with Alvania NLGI #2 grease

Grease output (in.³/min. [cm³/min.]),

1,000 psi (69 bar) back pressure

Hydraulic flow input

Temperature

°F (°C)

1 gal./min

(4 l/min.)

2 gal./min.

(8 l/min)

3 gal./min.

(11 l/min.)

4 gal./min.

(15 l/min.)

5 gal./min

(19 l/min.)

6 gal./min.

(23 l/min.)

7 gal./min.

(26 l/min.)

80 (27) 7 (115) 14 (229) 21 (344) 28 (459) 34 (557) 40 (656) 45 (737)

40 (4) 7 (115) 14 (229) 21 (344) 28 (459) 33 (541) 39 (623) 41 (642)

20 (-7) 6 (98) 13 (213) 17 (279) 22 (361) 28 (459) 32 (594) 36 (590)

0 (-18) 6 (98) 11 (180) 15 (245) 19 (310) 23 (376) 27 (442) 30 (491)

-10 (-23) 5 (82) 7 (115) 8 (131) 9 (148) 10 (164) 12 (197) 13 (213)

-20 (-29) 4 (66) 6 (98) 8 (131) 10 (164) 12 (197) 14 (229) 15 (245)

Solenoid valve with manual override standard on Model 85247, 85670 and 85675 optional on other models.

361104

50014

1)

66246

1)

50034

1)

249616

1)

66246

51026

1)

Included in spacer kit 272013

Mount the pump securely on the drum

cover. Failure to do so could result in

personal injury and equipment damage.

WARNING

Do not exceed 450 psi (32 bar) working

hydraulic pressure. Use high pressure

components to reduce risk of serious in-

jury including fluid injection and splash-

ing in the eyes or on the skin. All acces-

sories connected to the pump outlet

must have at least 5,000 psi (350 bar)

minimum hydraulic operating pressure.

All accessories connected to the pump

inlet must have at least 3,500 psi

(241 bar) minimum working pressure.

WARNING

5

To order call 1-800-548-1191 or visit www.partdeal.com - info@partdeal.com

Loading...

Loading...