4

10.

1500 SERIES VALVE

TEST PROCEDURE

10.1

NOTE: 90 PSI minimum supply and pilot pressure

10.2

Rotate lever in the fill direction and fill air springs.

10.3

Rotate lever in the exhaust direction and exhaust air.

NOTE: if fill and exhaust modes are backwards, ex-

haust air from suspension, loosen lever screw enough

to separate lever from valve. Rotate lever 180

o

, reseat

in cross pattern of valve and retighten lever screw. Ro-

tate lever 180

o

to original position. Retest fill and ex-

haust modes.

11. RIDE HEIGHT ADJUSTMENT

11.1

Manually air up the valve to ride height. Check the vehi-

cle manufacturer’s ride height recommendations for

correct height.

11.2

Reconnect linkage to end of lever.

11.3

Measure ride height.

11.4

Readjust ride height by loosening the lever screw

enough to rotate the bottom to fill or exhaust the air

until the correct ride height is attained.

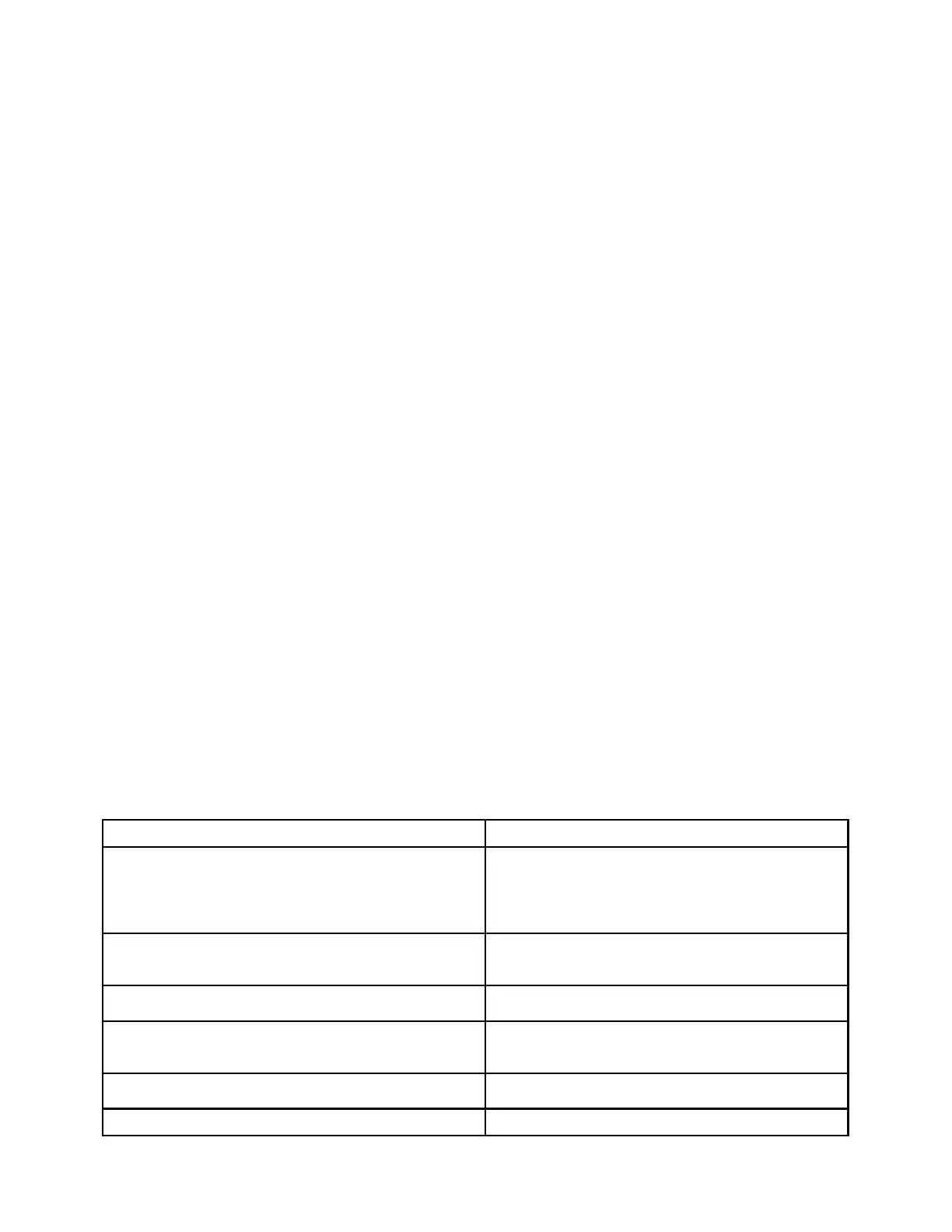

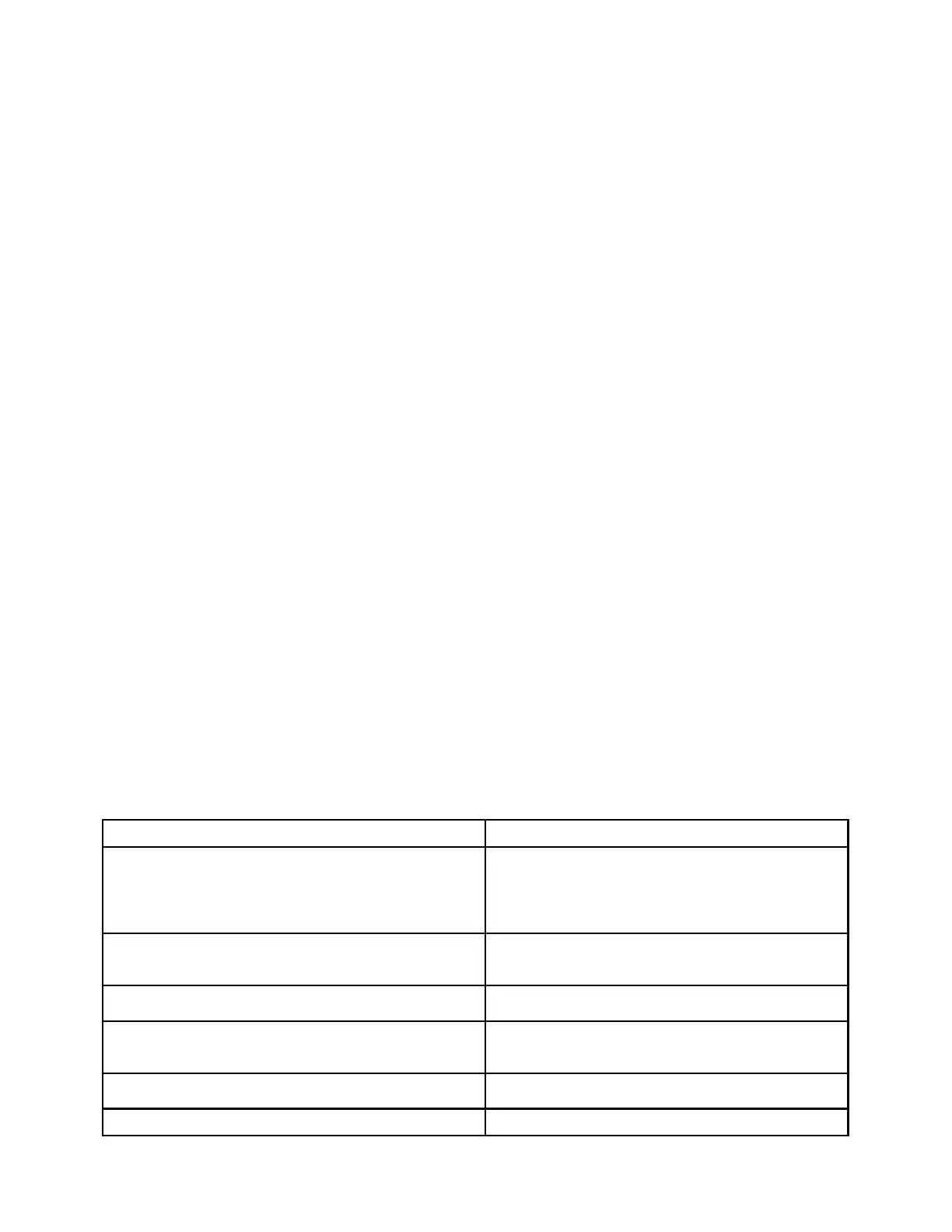

PROBLEM POSSIBLE CAUSE

Air springs flat

Obstructed air line

Insufficient air pressure to suspension

Defective Pressure Protection Valve

Defective HCV (see test procedure)

Air leak in system

Air springs raise to full height but do not exhaust

Obstructed air line

Supply line installed in suspension port

Defective HCV (see test procedure)

Air springs deflate when parked

Leak in air system (check with soapy water)

Defective HCV (see test procedure)

Suspension will not maintain proper height

Obstructed air line

Ride height out of adjustment

Defective HCV (see test procedure)

Hard ride

Ride height out of adjustment (readjust per

vehicle service manual)

Ride height unequal side to side for (2) valve system Reset ride height on each side

11.5

Tighten the lever screw to 50 – 60 in lbs.

11.6

Double check the ride height measurement by dumping

the suspension and allowing the 1500 Series Valve to

air up to ride height (Disconnect and reconnect the link-

age).

11.6

Remeasure ride height and adjust if necessary.

12. HCV INSTALLATION NOTES

12.1

Optimal lever angle for full up or down travel is be-

tween 20

o

and 45

o

12.2

Mount HCV with supply port horizontal or pointing up

13. HCV TEST PROCEDURE

13.1

1. With a minimum of 90 psi at the supply port, rotate

the lever up (as indicated on the side of the valve)

30° to 45°. Air should flow into the air springs.

2. Rotate the lever to the neutral position. Air flow

should stop.

3. Rotate the lever down 30

°

to 45

°

. Air should ex-

haust from the air springs.

4. Rotate the lever to the neutral position. Air flow

should stop.

5. If a valve fails to flow air or shut off as specified,

replace with a new one.

14. REASONS TO REPLACE THE HCV

1. HCV did not pass the test procedure

2. Air leaks form the HCV

3.

HCV is damaged

15. TROUBLESHOOTING

Loading...

Loading...