M & MA Series Meters

10

Get the latest PDF manual:

https://www.lcmeter.com/resources/technical/manuals

Mobile/online version of this manual:

https://www.lcmeter.com/manuals

·

Meter Start Up and Operation

·

Reversing the Meter Registration

·

Setting the Standard Adjuster

How LC Meters Work

Liquid Controls meters are positive displacement meters. They are designed for liquid

measurement in both custody-transfer and process-control applications. They can be installed

in pump or gravity flow systems. Because of their simple design, they are easy to maintain,

and easy to adapt to a variety of systems.

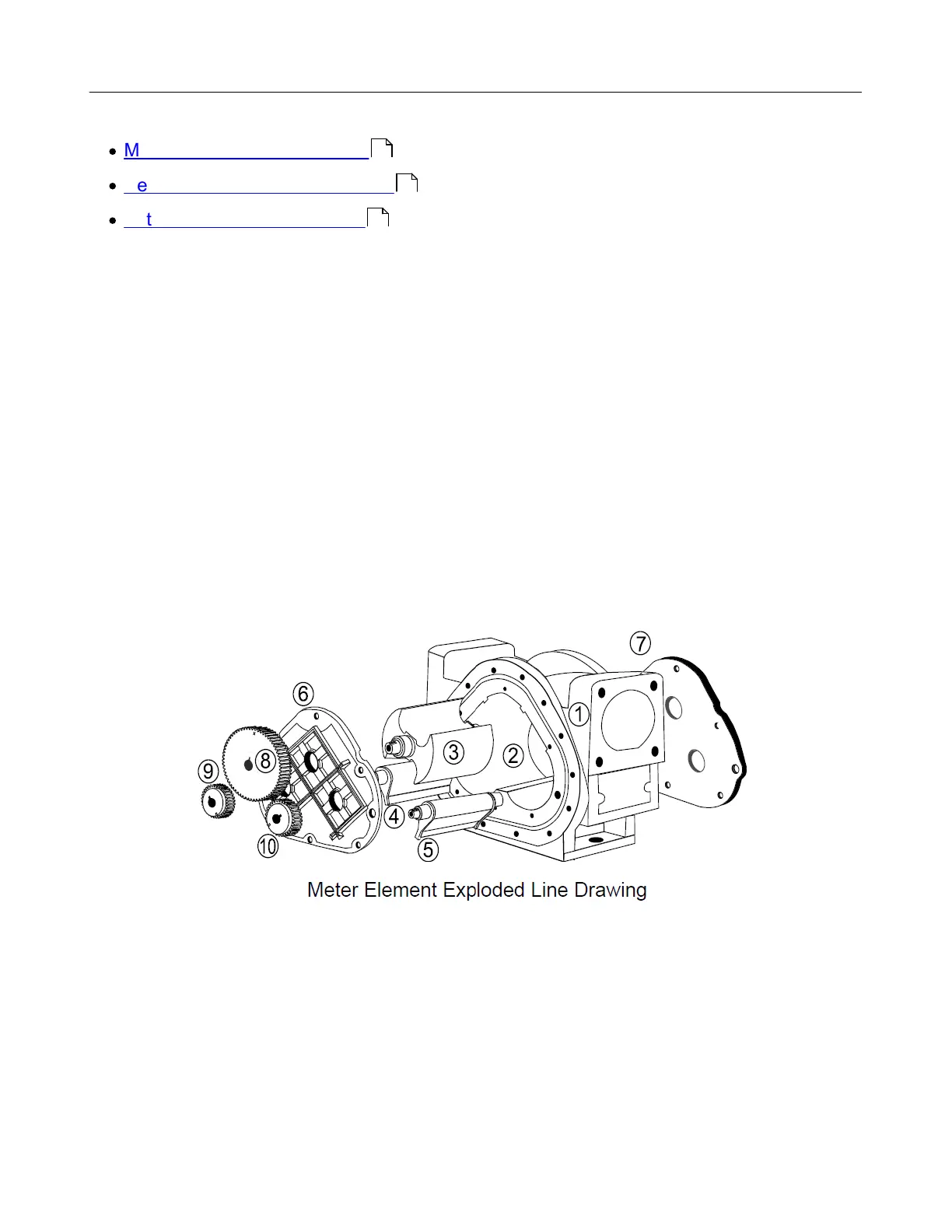

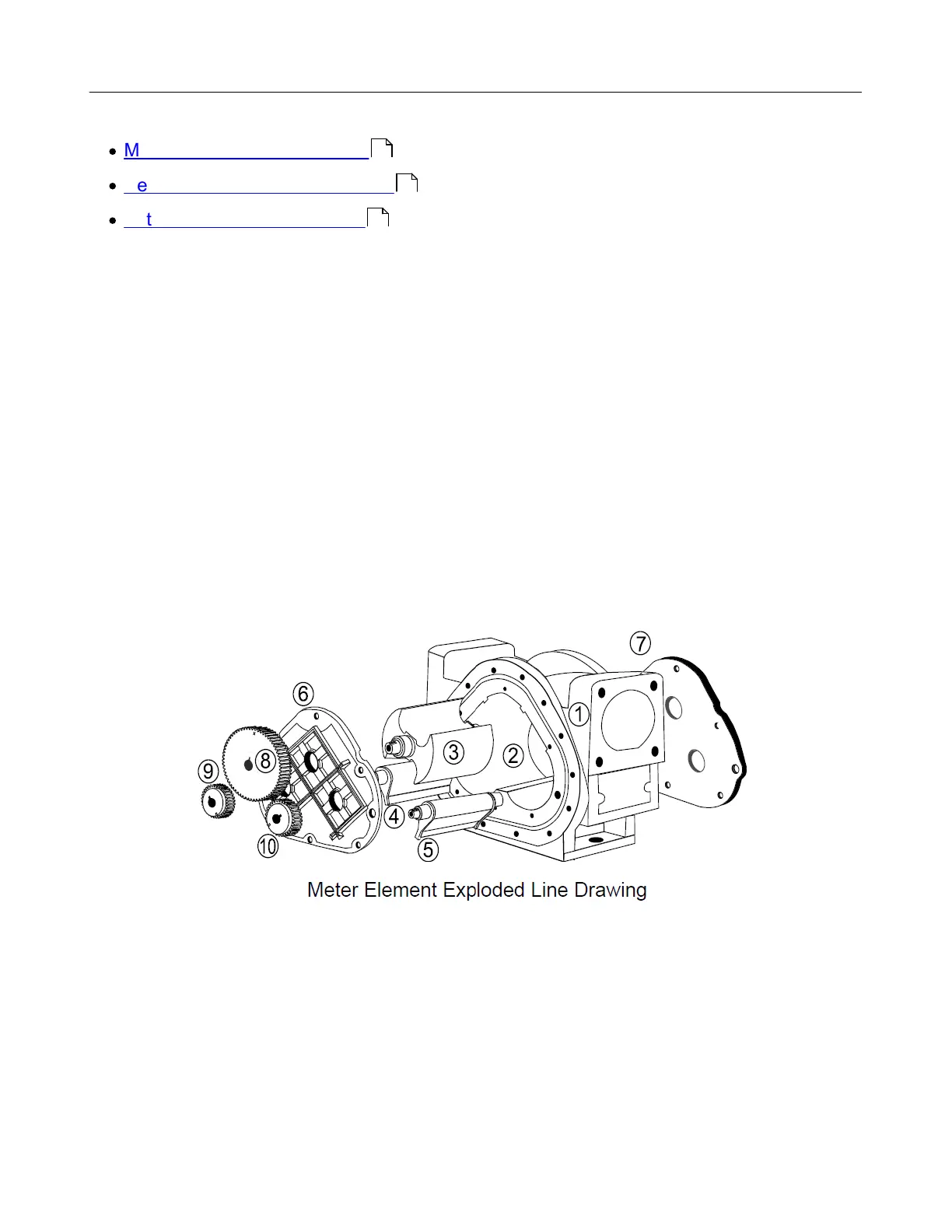

The meter housing (1) is designed with three cylindrical bores (2). Three rotors, the blocking

rotor (3) and two displacement rotors (4, 5), turn in synchronized relationship within the bores.

The three rotors are supported by bearing plates (6, 7). The ends of the rotors protrude

through the bearing plates. The blocking rotor gear (8) is placed on the end of the blocking

rotor. The displacement rotor gears (9, 10) are placed on the ends of the displacement rotors.

These gears create the synchronized timed relationship between the three rotors.

As fluid moves through the meter housing, the rotor assembly turns. The liquid is broken into

uniform sections by the turning rotors. Fluid displacement occurs simultaneously. As fluid

enters, another portion of the fluid is being partitioned and measured. At the same time, the

fluid ahead of it is displaced out of the meter and into the discharge line. Since the volume of

the bores is known, and the same amount of fluid passes through the meter during each

revolution of the blocking rotor, the exact volume of liquid that has passed through the meter

can be determined with a high degree of

accuracy.

16

18

20

Loading...

Loading...