Page 8 Maxmig 210 IMA 578BLA

2. OPERATING INSTRUCTIONS

2.1 Duty Cycle

The machine is rated at the following duty cycles:

(1) Based on 10 min. time period (i.e., for 25% duty cycle, it is

2.5 minutes actual welding and 7.5 minutes with no welding

output, but with the input power remaining on keeping the

cooling fan operative.)

2.2 Control Panel

a) Power Switch

The mains power switch is incorporated in the “coarse”

output voltage control rotary switch. In the “0” positions the

input mains power is switched off.

b) Pilot Light

This light illuminates when the input mains power is

switched on.

c) Volts Control

The output voltage is controlled by two rotary switches.

One rotary switch provides two “coarse” voltage settings

as well as switching the mains power on. The other rotary

switch provides the user with a selection of eight “fine”

voltage settings. The selection between these two

switches allows the user to select any one of sixteen

welding voltages.

The approximate weld voltages for the switch positions

are:

d) Wire Feed Speed Control *

Use this control to adjust the speed at which the electrode

wire feeds when welding. This is in effect a current control

as the power source will deliver the current necessary to

melt the wire. The higher the speed, the more current will

be required. Wire feed speed range is approximately 1 to

20 meters/min (40 to 790 inches/min.).

Operation of the gun trigger switches the wire feed motor

on and off, depending upon the mode setting. The wire

feed motor is dynamically braked to minimise wire overrun

after welding has ceased.

Welding voltage is available immediately the gun trigger is

operated, but when welding is stopped there is a factory

set delay of approximately 1/2 sec. after wire feed has

stopped to allow the electrode to burn back slightly and

prevent sticking in the crater.

e) Spot Welding *

In spot welding mode welding takes place for a pre-set

time and then stops automatically. Welding time is

adjustable between 0.5 sec. and 4 sec. by operation of the

spot weld control on the front panel. There is a positive

click in the extreme anti-clockwise position to indicate that

the spot weld feature is “off”.

* Mounted on machine control panel for Integrated units.

Mounted on remote wire feeder for Remote units.

Duty Cycle

(1)

Amps Volts

25% 210 24.5

34% 180 23

100% 120 20

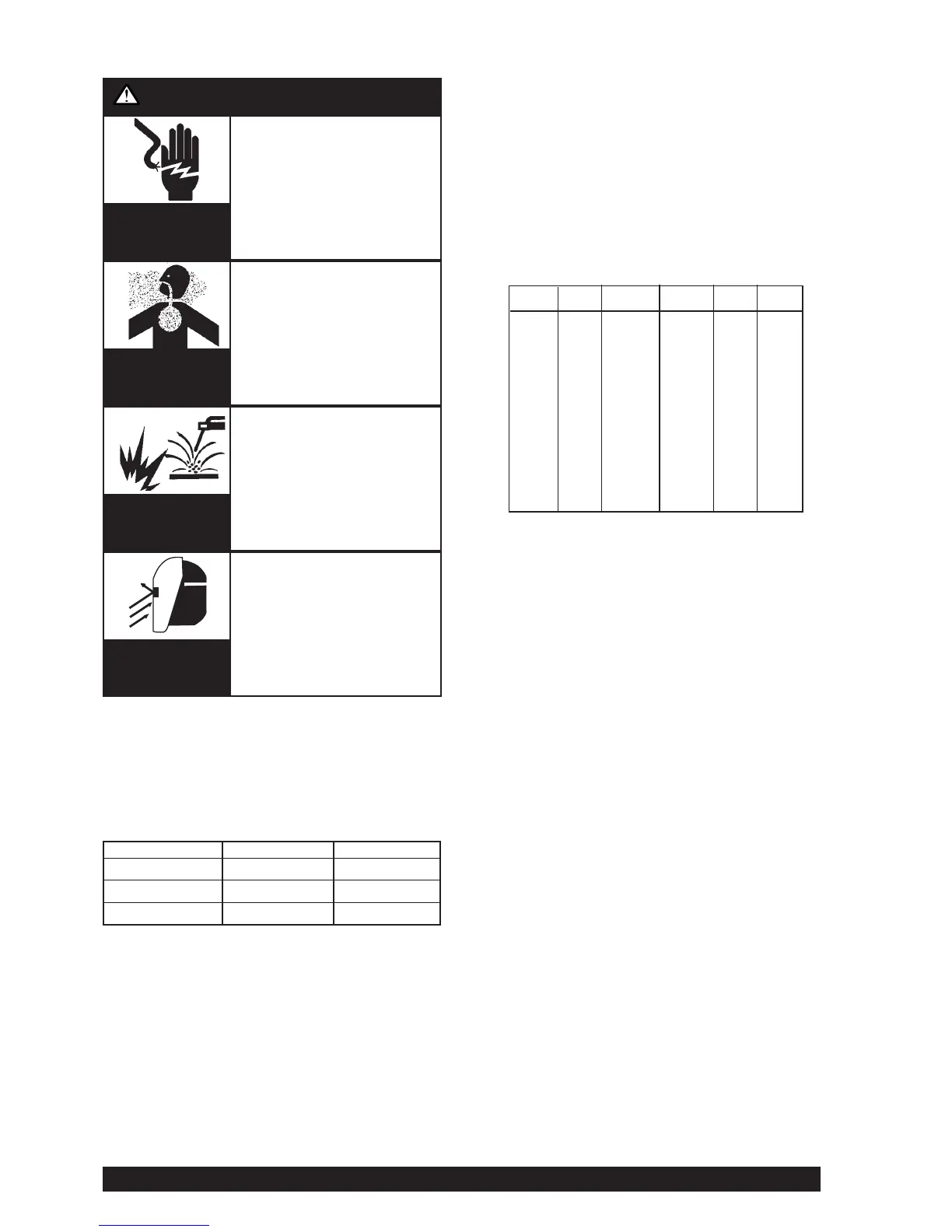

Coarse Fine Volts Coarse Fine Volts

1 1 13.0 2 1 18.0

1 2 13.5 2 2 19.0

1 3 14.0 2 3 20.0

1 4 14.5 2 4 21.0

1 5 15.5 2 5 22.0

1 6 16.0 2 6 23.0

1 7 17.0 2 7 24.0

1 8 17.5 2 8 25.5

WARNING

ELECTRIC

SHOCK

can kill

FUMES AND

GASES can be

dangerous

WELDING SPARKS

can cause fire

or explosion

ARC RAYS

can burn.

• Do not touch electrically live

parts or electrode with skin or

wet clothing.

• Insulate yourself from work

and ground.

• Always wear dry insulating

gloves.

• Keep your head out of fumes.

• Use ventilation or exhaust to

remove fumes from breathing

zone.

• Keep flammable material

away.

• Do not weld upon containers

which have held

combustibles.

• Wear eye, ear and body

protection.

IMPORTANT SAFETY NOTE: In 2T mode {refer 2.2 (h)}, this

DC Constant Voltage wire welder provides “COLD” electrode

when the gun trigger is not operated. Conversely, the output

terminals are “LIVE” when the gun trigger is “activated” when

pressed in 2T mode, or triggered on in 4T mode.

Loading...

Loading...