IMA 578BLA Maxmig 210 Page 9

f) Gas Purge *

Use the gas purge push button to operate the gas solenoid

to purge air from the hose after connecting a new gas

cylinder. Gas purge will only operate while the button is

held in.

g) Wire Inch *

Use this push button to operate the wire feed motor and

“cold” inch the wire.

h) 2T/4T Operation *

A two position switch on the front panel provides two

modes of operation of the gun trigger. In 2T mode, the gun

trigger is pressed to start welding and released to stop.

In 4T mode, pressing the gun trigger only operates the gas

solenoid, allowing shielding gas to flow. Releasing the

trigger activates the contactor which starts the wire feed

motor and connects welding current to the wire so that

welding may commence. To stop welding, the trigger must

again be operated; pressing it stops the wire feed,

activates the burn back time delay and opens the

contactor after the pre-set burn back time. Releasing the

trigger stops the gas flow.

To recommence welding, the above cycle must be

repeated.

i) Over temperature light

Indicates that the thermostats have operated to protect

unit from over temperature.

* Mounted on machine control panel for Integrated units.

Mounted on remote wire feeder for Remote units.

3.Setting Up for Welding

The following items are required:

1) A reel of wire of suitable size and type .

2) A suitable gun and cable assembly with a “Euro”

connector and the correct tip and, if necessary gas

nozzle for the consumable being used. (A Maxmig 150

MIG gun is supplied).

3) Correct drive rolls for the wire size and type to be used.

The wire feeder is supplied with a 0.9/1.2mm hard wire

feed roll as standard; drive rolls for other types and

sizes are available as spare parts. (see table on page

10).

4) A work return cable and clamp.(supplied)

5) Normal welding accessories including helmet or hand

shield with suitable lens, gloves etc.

6) If a gas shielded process is to be used, a cylinder of

appropriate gas is required. (Regulator/flowmeter and

hose are supplied.) If gas shielding is required, connect

the gas hose.

Remember that gas cylinders may explode if damaged, so

ensure that all gas cylinders are securely mounted.

Ensure that the correct type and size wire feed rolls are fitted. In

replacing wire feed rolls, ensure that the key and keyway are

correctly positioned and tighten the knurled locking screw

securely.

Fit a spool of appropriate wire onto the 50mm spool hub so that,

for the integrated model, as wire is fed the spool turns anti-

clockwise when looking at the spool. For the remote unit, the unit

spool must turn clockwise as the wire is fed. Carefully release

the end of the wire from the spool ensuring that the released end

is held to stop the wire from unravelling. Cut off the end kink to

give a smooth straight end of wire.

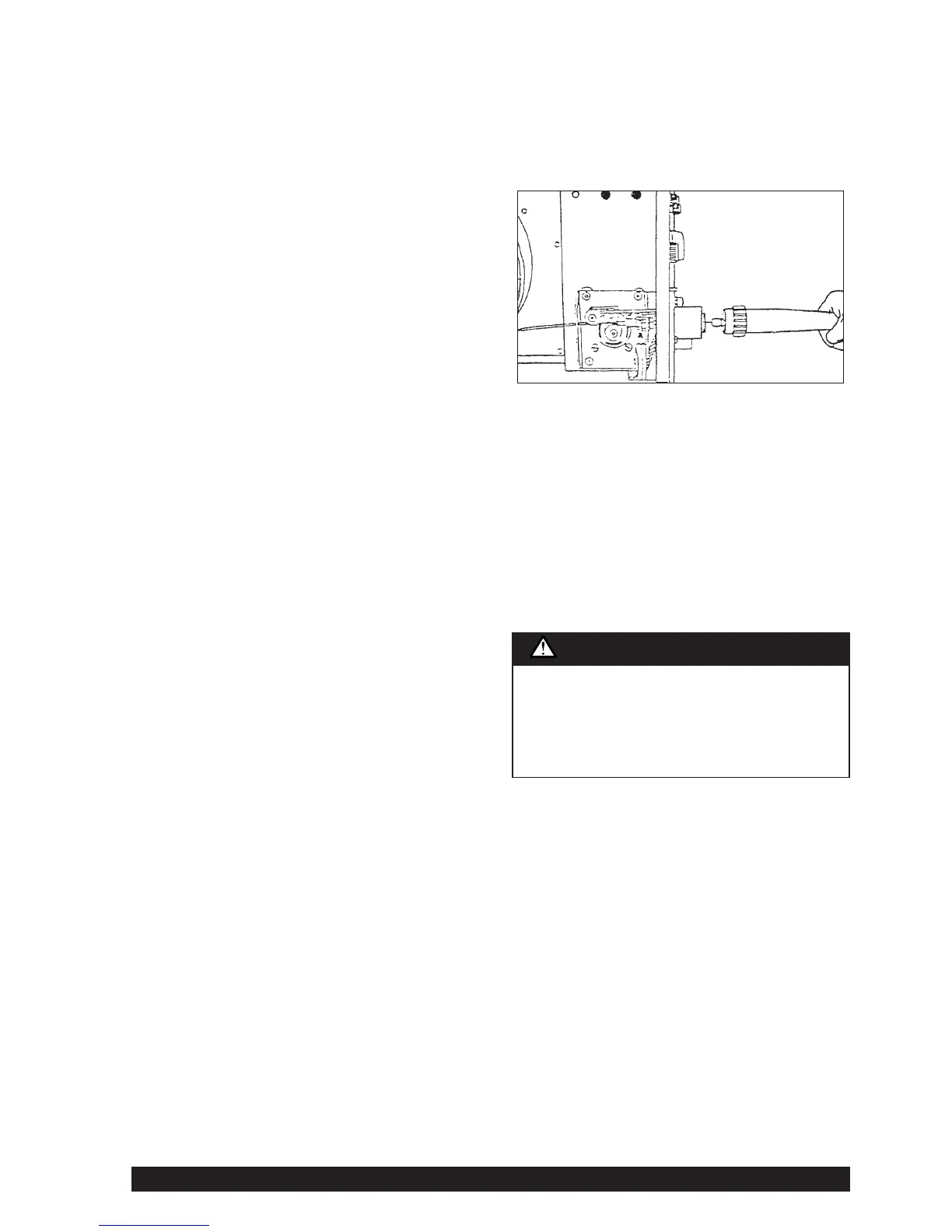

Obtain a gap between the wire feed roll and the pressure roll by

lifting the cam latch. Feed the wire end into the guide tube,

between the drive rolls, and into the “Euro” connector guide until

it protrudes about 20mm out of the front of the “Euro” connector.

Close the drive rolls by lowering the cam latch ensuring the rolls

firmly hold the wire. Adjust the tension so that wire feeds

smoothly.

Do not overtighten.

Fit the gun and cable assembly onto the “Euro” connector by

slipping the end of wire into the cable wire hole. Tighten the

“Euro” connector lock ring.

Activate the power source, set the wire feed speed to 4 on the

dial and press the wire inch push button. The wire feed roll

should turn, feeding the wire further up the gun and cable

assembly.

Ensure there are no kinks or sharp bends in the gun cable and

hold the wire inch button until the wire emerges from the gun. It

is good practice to remove the tip when first feeding a new coil of

wire, then refitting over the wire and tightening.

Cut off the end of the wire leaving 10mm to 15mm stick-out.

Select required polarity. See Section 1.5 - Output Polarity

Connection.

4.Welding

Put into 2T mode.

Select the output voltage required to suit the job by setting the

coarse and fine rotary switches.

Before beginning welding, ensure the wire protrudes from the

gun tip by approximately 10-15mm. Ensure welding shield and

other protective clothing are in place. Present the protruding

electrode just off the work. Maintain a steady grip on the gun,

protect your eyes with a welding shield, then press and hold the

gun trigger to create the arc.

If it is necessary to adjust the weld voltage, stop welding before

changing either or both of the rotary switches.

Adjust the wire feed speed as necessary to suit the job. At the

completion of the weld, release the gun trigger and pull the gun

away from the work to stop the arc.

4T mode should only be used for long welds by experienced

operators.

Integrated machine

When the gun trigger is pressed (2T mode) or pressed

and released the first time (4T mode), the wire is at

welding voltage. The wire should never touch the case of

the wire feeder. If it does, it is possible for the wire to arc

to the case.

Any wire overrun should be avoided.

WARNING

Loading...

Loading...