4.1 AUTOMATIC DEFROST

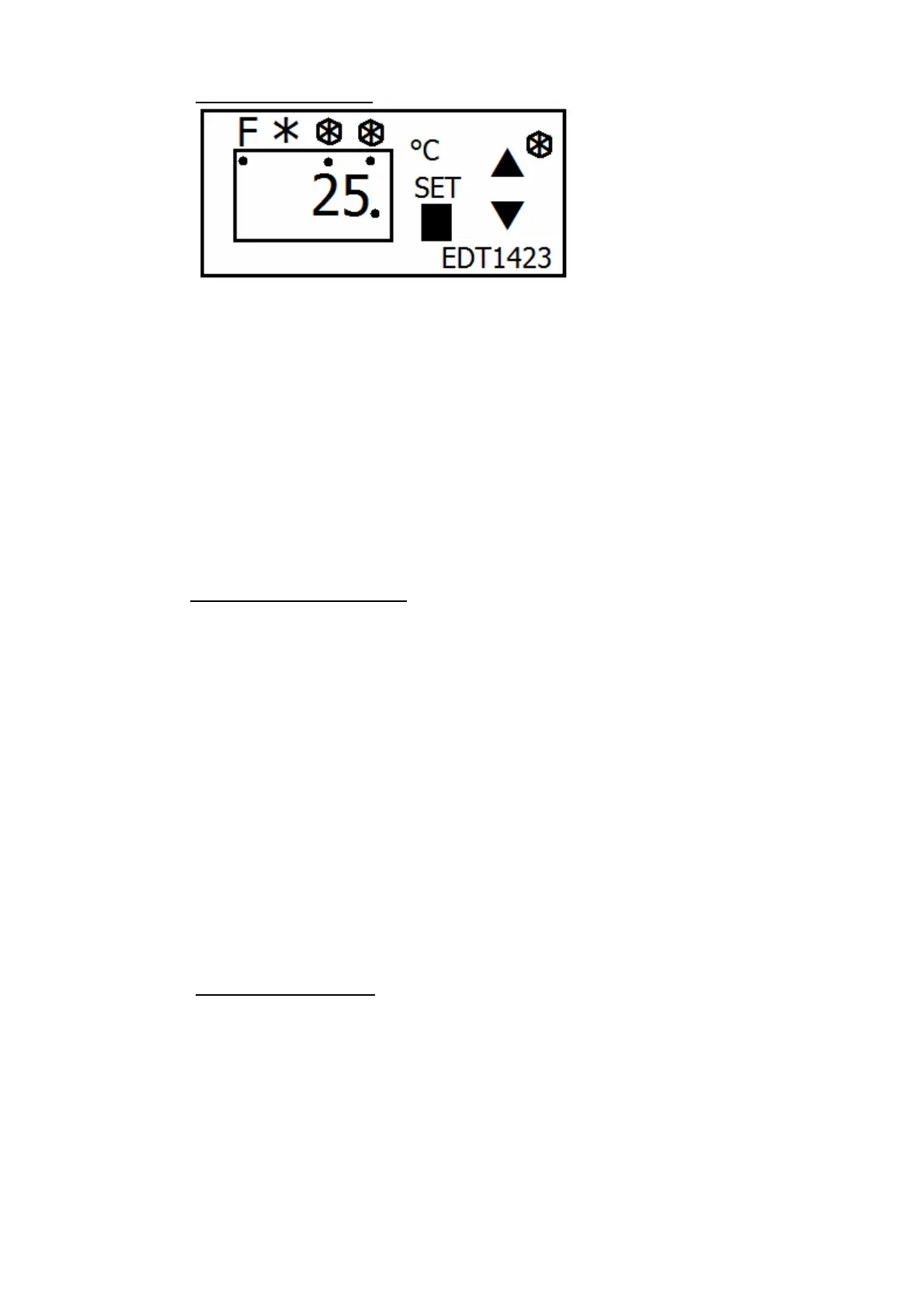

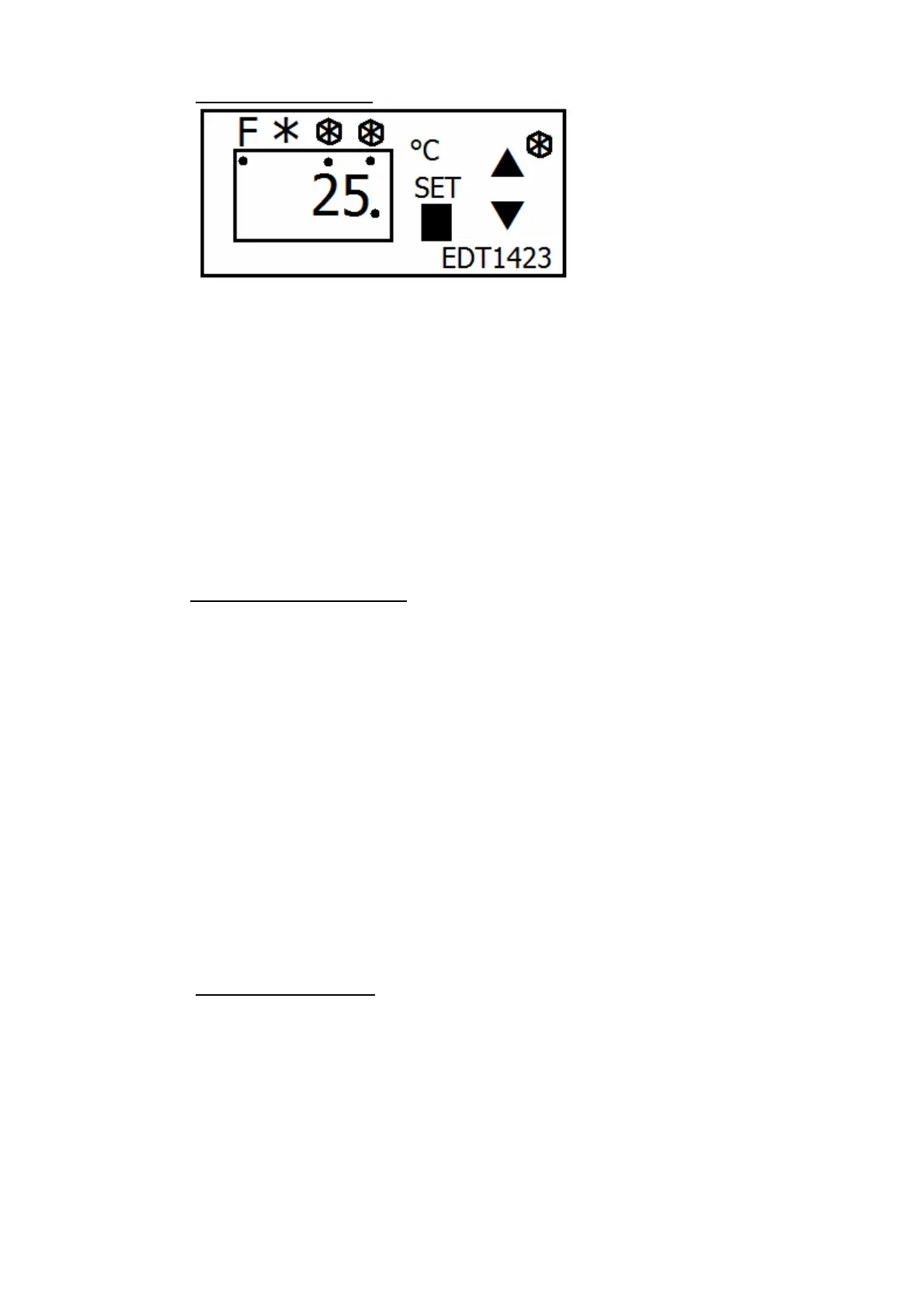

Defrost Controller

On Series 3, and optionally on Series 1A and 2, the cabinet is set to defrost every 6

hours, however the defrost controller will sense whether this is required or not. This

controller is factory set for optimum use and is locked for protection against misuse.

The defrost will give a slight rise in air temperature. If this rise should create any

problems the defrost can be over-ridden by the defrost isolator switch on the rear of

the back panel. On Series 4 the defrost occurs 4 times every 24 hours; duration is

controlled by the ice build up internally.

Please note that this controller will always display the figure 25 which is

not to do with any temperature setting, this is merely a function setting.

On Series 1A, 2 and Series 3 cabinets, any defrost water drains away to a tray

mounted on the compressor. On Series 4 cabinets the water drains into a tray

(supplied) which must be fitted in the special tracks mounted underneath the cooled

incubator during installation. On all models this water evaporates harmlessly away.

4.2 HIGH/LOW ALARM OPTION

The high/low alarm is a manually adjusted alarm option fitted to the instrument’s

front panel. When fitted, this instrument supplements the digital control on the

control panel with a contact thermometer, having a ‘Red’ upper limit pointer and a

‘Green’ lower limit pointer. This unit, being electro-mechanical, is not dependent on

the normal control electronics and therefore will take over control in an emergency

situation and maintain some form of control however coarse.

In the event of an alarm condition, the following action will be taken:

An audible alarm will sound and a secondary safety system will be activated,

preventing the cooled incubator temperature from rising above or falling below the

set alarm limits.

To set up, ensure the pointer is wound well up in the case of the Red and down in

the case of the Green. Set the control temperature by means of the digital controller

and allow the incubator to stabilise at the required control point. Once this is

achieved the pointers may be realigned as close as required to the set point after

making due allowances for contingencies such as door opening etc.

4.3 INNER PERSPEX DOOR

On incubators fitted with this feature and depending on the temperature difference

between the inner working chamber and the space between the inner and outer

doors, some slight distortion may occur to the Perspex door.

Loading...

Loading...