1 - 4

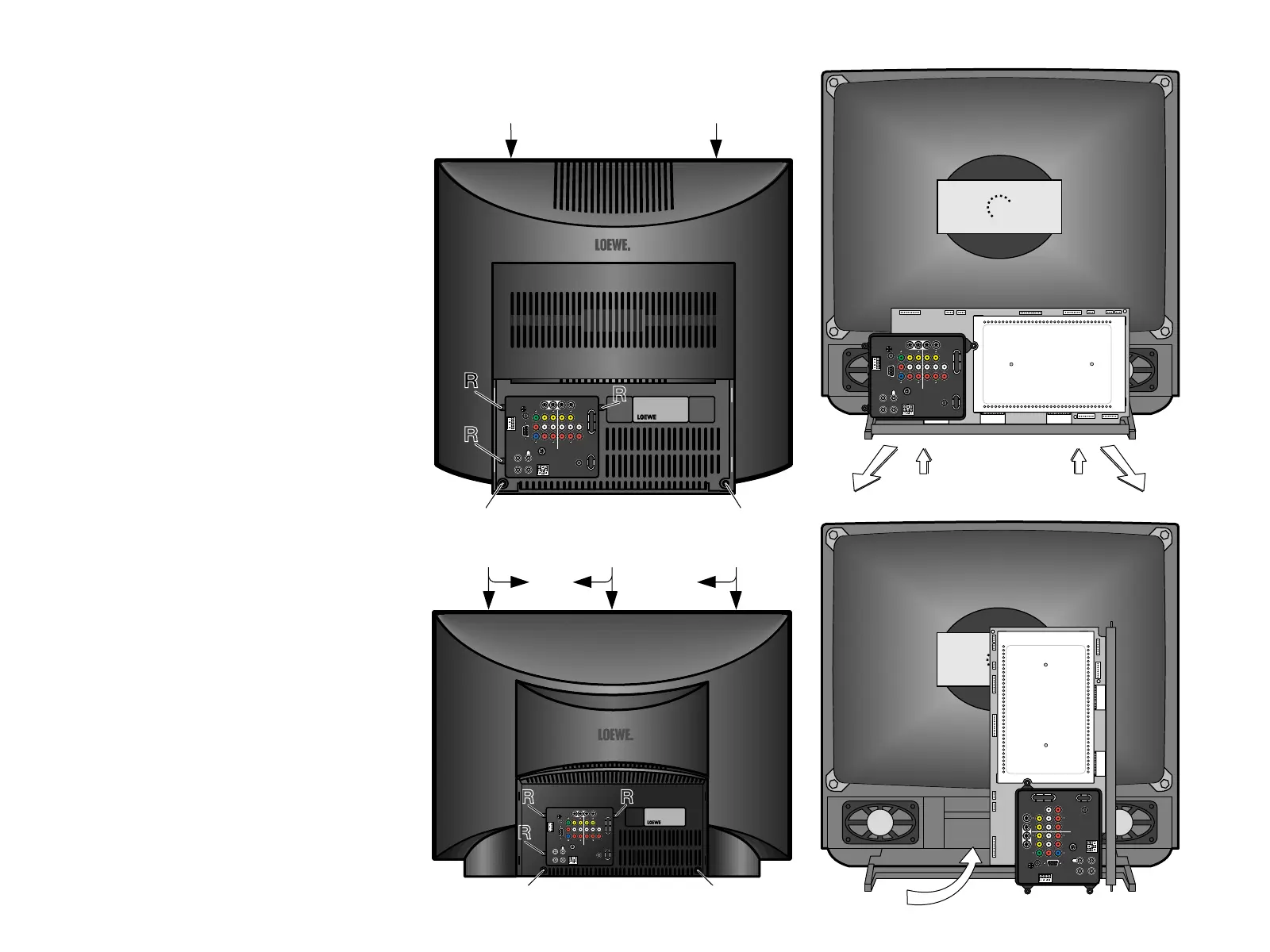

Rear panel removal

Unscrew the five rear panel screws R to remove the rear panel.

Insert screw driver into recess V. Depress interlocking and at the

same time slide rear panel to the rear (fig. 2a).

ACO 9303 MB / Press interlocking in direction of arrows and at

the same time slide rear panel to the rear (fig. 2b).

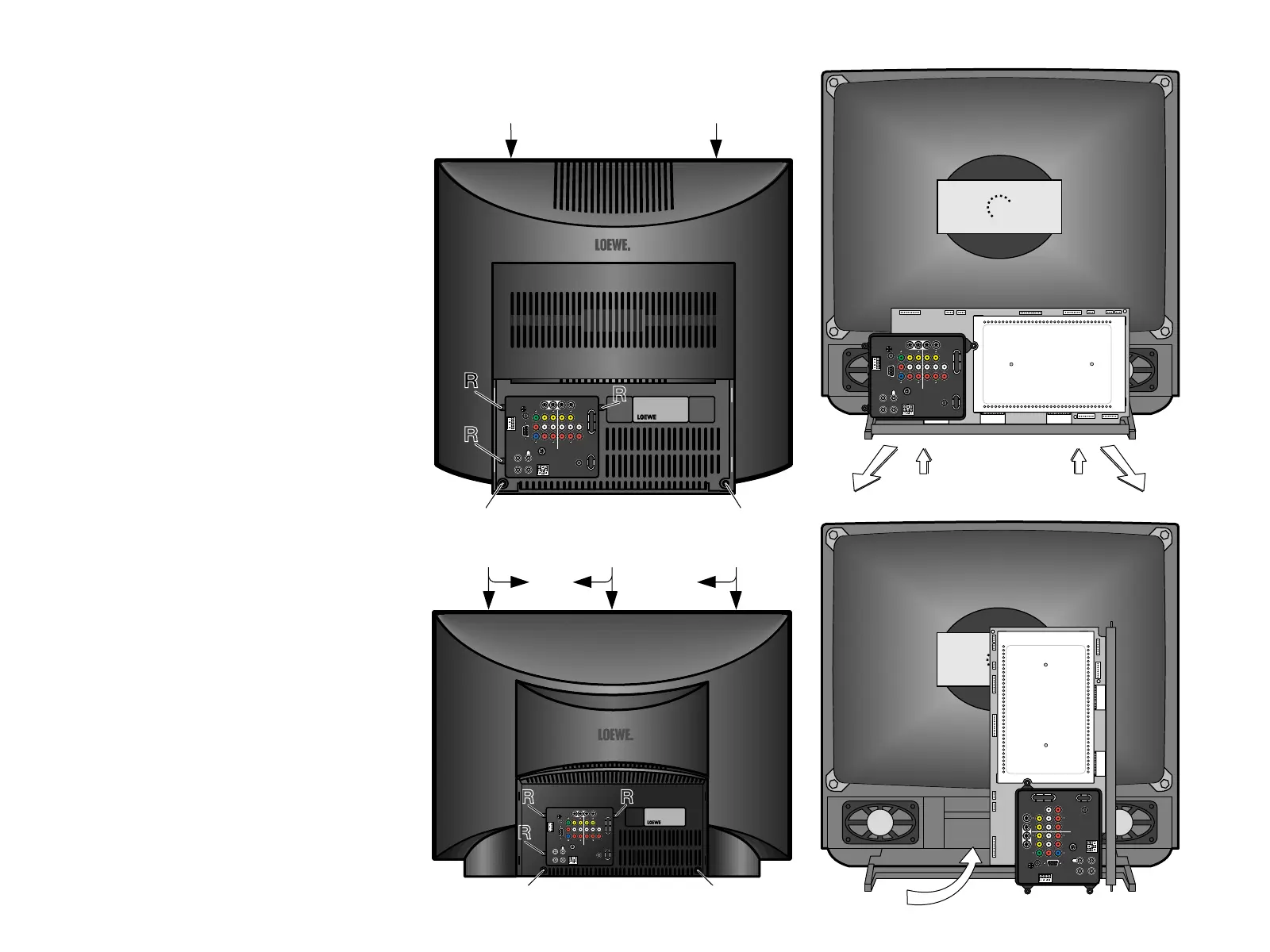

How to move the chassis into the service position

1. Hold and lift the rear of the chassis and gently pull the chas-

sis toward you (fig. 3).

2. Undo the cable fixtures. Turn the chassis through 90°anti-

clockwise and place the chassis behind the set (fig. 4).

3. After servicing ensure all wiring is returned to its original po-

sition and fixed.

Service position for the signal board

1. Remove the signal board from the main chassis (Basic board),

ensuring all leads are disconnected.

2. Remove the four six (A) (fig. 5) from the plastic AV cover and

unclip the AV cover from the signal board.

3. Remove the front metal cover from the signal board (fig. 6).

Do the same for the rear metal cover (fig. 7).

4. Fit the three extension leads to the signal board making sure

that the signal board does not touch the basic board (fig. 8).

5. After servicing ensure all wiring is returned to its original po-

sition and fixed.

Note:

The extension lead wire kit is supplied as a service kit. (Part

number 3 x 396-90288.938).

☞ Repair information for the signal board

MediaPlus

There is any error on the signal board, please proceed as de-

scribed:

- Remove the EAROM (I 1891) from the printed circuit board. The

TV is able to keep running.

- If you get a static picture, the EAROM is out of order (possible

geometry errors remain unconsidered).

- If the error is still there, it's because of another component on

the signal board.

- If you want to change the signal board at the service head office,

insert the EAROM from the damaged signal board into the new

one. So you don't need to make the alignment and the program-

ming of the TV set.

Important!

Please remove the AV cover at the damaged signal board.

Rear panel removal

How to move the chassis into the service

position

Fig. 3

ANTENNA

LOOP B

1

INPUT

SERVICE

SUBWOOFER

STAND

CLASS 2 WIRING

TUNER MONITOR AUDIO

OUTPUT

2

Y

Cb

C

r

V

L

L

R

R

AUDIO

VGA

RRRR

LLLL

VVV

S-VIDEO S-VIDEO R

C-VIDEO

VGA

EXT. SP.2

CLASS 2 WIRING

IR

RC5/

RC6

Fig. 4

90°

ANTENNA

LOOP B

1

INPUT

SERVICE

SUBWOOFER

STAND

CLASS 2 WIRING

TUNER MONITOR AUDIO

OUTPUT

2

Y

Cb

C

r

V

L

L

R

R

AUDIO

VGA

RRRR

LLLL

VVV

S-VIDEO S-VIDEO R

C-VIDEO

VGA

EXT. SP.2

CLASS 2 WIRING

IR

RC5/

RC6

VV

Fig. 2a

R

R

R

RR

ANTENNA

LOOP B

1

INPUT

SERVICE

SUBWOOFER

STAND

CLASS 2 WIRING

TUNER MONITOR AUDIO

OUTPUT

2

Y

Cb

C

r

V

L

L

R

R

AUDIO

VGA

RRRR

LLLL

VVV

S-VIDEO S-VIDEO R

C-VIDEO

VGA

EXT. SP.2

CLASS 2 WIRING

IR

RC5/

RC6

Fig. 2b

R

R

R

R

VVV

ACO9303

R

ANTENNA

LOOP B

1

INPUT

SERVICE

SUBWOOFER

STAND

CLASS 2 WIRING

TUNER MONITOR AUDIO

OUTPUT

2

Y

Cb

C

r

V

L

L

R

R

AUDIO

VGA

RRRR

LLLL

VVV

S-VIDEO S-VIDEO R

C-VIDEO

VGA

EXT. SP.2

CLASS 2 WIRING

IR

RC5/

RC6

Loading...

Loading...