Troubleshooting

- 48 - 02.20909.2710.1-06

9 Troubleshooting

9.1 Monitoring temperature

The temperature of the heat sink is constantly monitored via a temperaure sensor. This sensor is a tem-

perature dependent resistor (NTC = negative temperature coefficient). The higher the temperature, the

lower the resistance value of the sensor.

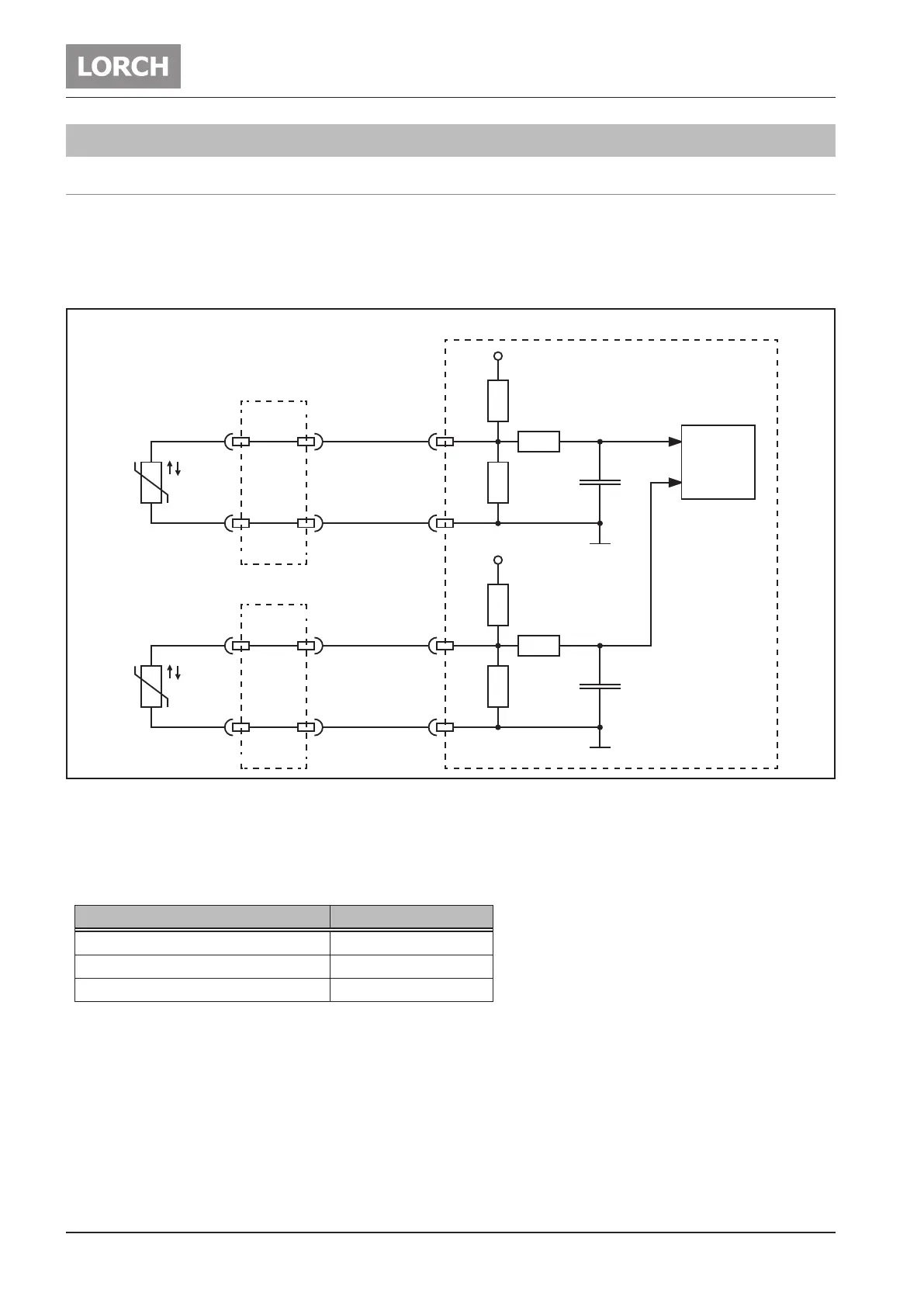

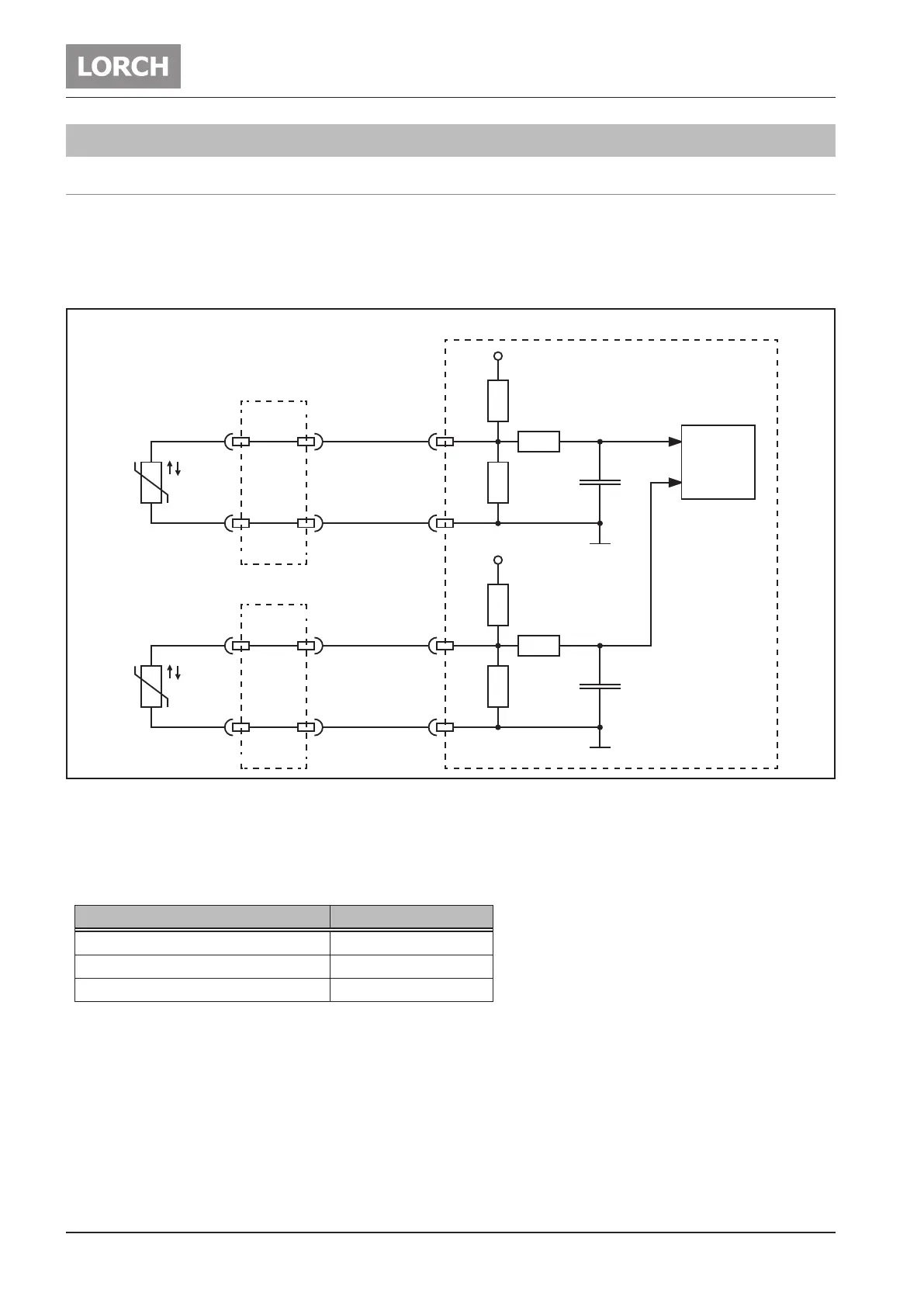

Schematic

DCDRV1

ϑ

X3/2

X3/1

X1/12

X1/4

DP-MAPRO

X1/12

X1/4

+3.3V

DCDRV2

ϑ

X3/2

X3/1

X1/12

X1/4

X4/12

X4/4

+3.3V

DSP

(Process)

Fig. 38: Temperature monitoring

The DSP is monitoring the temperature of the heatsink and as soon as the temperature reaches the pro-

grammed maximum value, the machine will stop and displays E01 (thermal overload).

The actual value of the temperature can be displayed at the front panel in menu Extras, Diagnosis, Module

Temperatures.

Machine type max. Temperature

S3, S3 mobile, P3000 mobile, P3500 77°C

S5, P4500 80°C

S8, P5500 75°C

Tab. 30: Maximum temperatures

If the connection of the sensors to the MAPRO is interrupted (loose contact at any of the connectors), the

machine will stop after some time and displays E13, because a rise of the temperature can not be detected.

There is a special overload program active in the DSP, which calculates and monitors the inside tempera

-

ture of the semiconductors (MOSFET power transistors). Before the inside temperature reaches a critical

limit, the machine will stop and displays E18 (Overload protection).

Loading...

Loading...