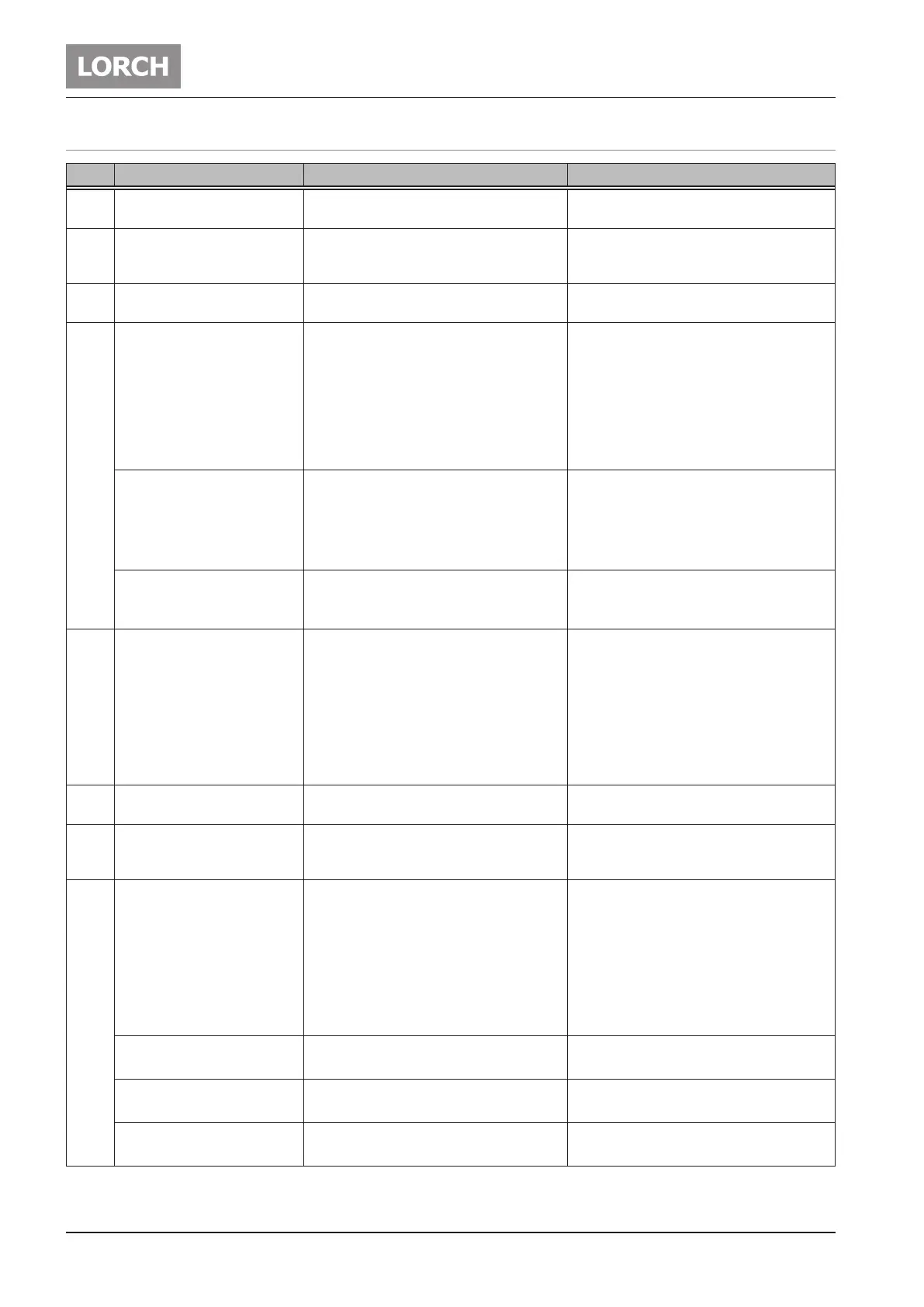

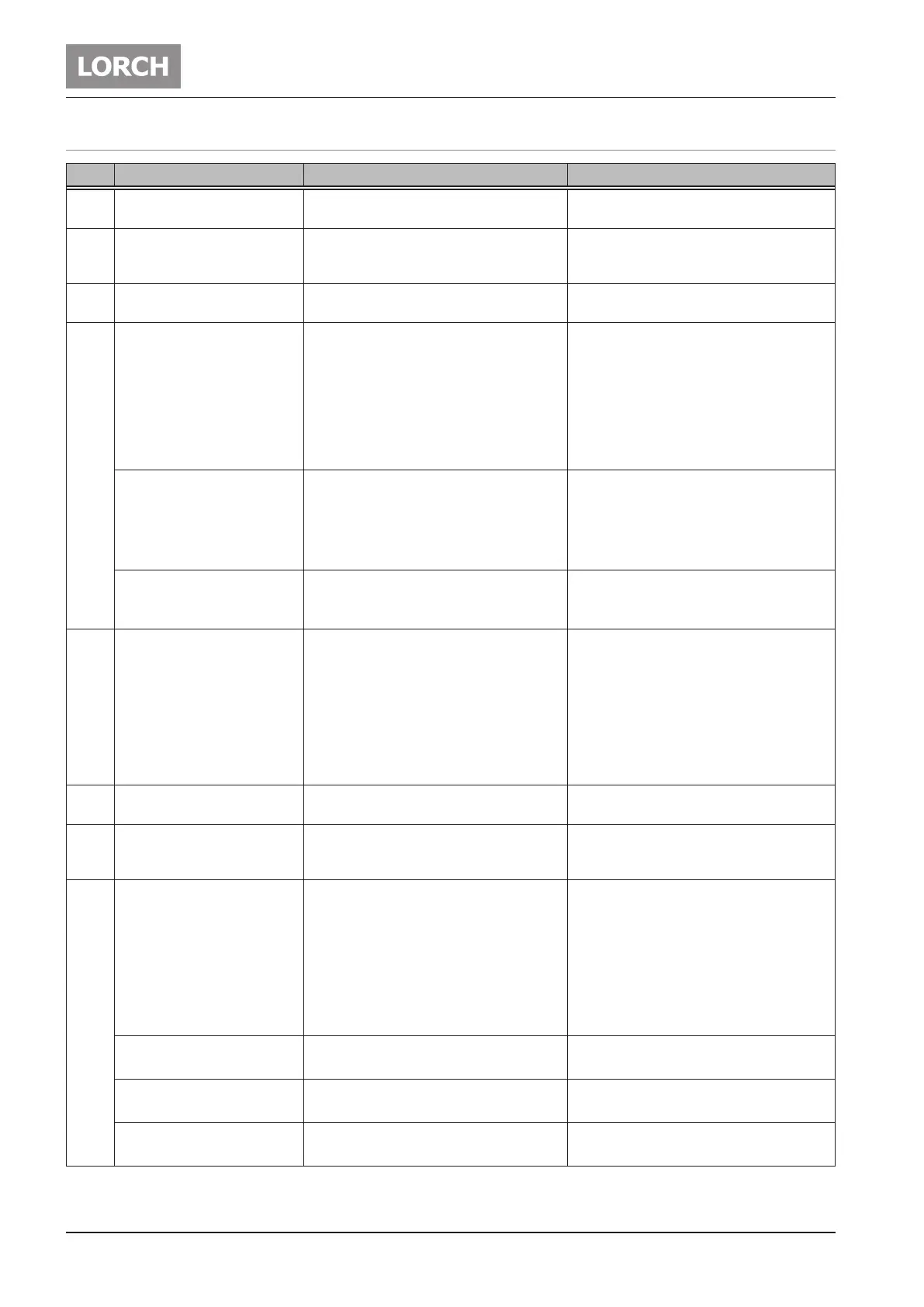

Troubleshooting

- 64 - 02.20909.2710.1-06

9.15 Malfunction Codes

code designation reason removal

E 01 Thermal overload thermal sensor of power unit meas-

ures a too high temperature

let machine cool down in standby (*1)

see page 48 for details

E 02 Mains overvoltage mains voltage too high

internal 24V supply > 36V

check mains voltage and control

transformer (*2)

see page 49 for details

E 03 Secondary overcurrent welding current is too high (>120%) check current sensor and its wiring

see page 50 for details

E 04 Stop/ Peripherals error

sub code -01

PE protection has detected a current

>15A flowing via the protective earth

wire of the mains cable

– check if the welding wire has con-

tact to metal parts of the housing or

parts with PE potential (wire spool

installation)

– check X26 on MAPRO board

– switch the machine off and on again

to reset the error message

see page 51 for details

Stop/ Peripherals error

sub code -02

the gas pressure switch (optional

feature) has opened: not enough gas

pressure left

– check / replace the gas bottle

– check X26 on MAPRO board

– switch the machine off and on again

to reset the error message

see page 51 for details

Stop/ Peripherals error

sub code -03

the gas flow rate is too low (only pos-

sible with installed flow sensor)

– check gas supply

– check min.gas flow setting in

customize menu

E 05 Cooling system error flowrate of the cooling liquid is too

low (< 0.3 l/min)

– pump is not working

– check level of cooling liquid and

flowrate (*3)

– check connectors of flow-meter

– check fuse SI7 (4A) on MAPRO

– check all hoses incl. torch and inter-

pass hose

see page 52 for details

E 06 Secondary overvoltage Master detects output voltage is too

high (>100V)

check wiring of power unit

see page 55 for details

E 07 EEProm checksum error no welding program stored or error

during reading from memory

switch the machine off and on again,

if necessary transfer the welding pro-

grams to machine again

E 08 Wire feed / tacho – power consumption of wire feed

motor too high

– tacho not connected to DMR X5

– CAN-Bus connection between

MAPRO and DMR is interfered/

blocked

– blow out torch package with com-

pressed air

– check wire feed unit

– check motor current (*4)

– check wiring of wire feed motor and

pc-board DMR

– check interpass hose package

see page 56 for details

M01 Motor overvoltage

(only at DMRPP)

supply voltage for motor driver is too

high (70V DC > 130V DC)

– check control transformer

– check motor supply

M02 Motor op. voltages

(only at DMRPP)

supply voltage for motor driver is too

low (70V DC < 30V DC)

– check control transformer

– check motor supply

M03 Motor 1 overcurrent

(only at DMRPP)

wire feed motor draws too much cur-

rent

– check wire feed unit and motor

– check motor current (*4)

Loading...

Loading...