• Do not use this pump to handle liquids containing

abrasive, solid, or fibrous substances.

•

Do not use the pump for flow rates beyond the

specified flow rates on the data plate.

Special applications

Contact the local sales and service representative in

the following cases:

•

If the density and/or viscosity value of the pump-

ed liquid exceeds the value of water, such as wa-

ter with glycol; as it may require a more powerful

motor.

• If the pumped liquid is chemically treated (for ex-

ample softened, deionized, demineralized etc.).

• Any situation that is different from the ones that is

described and relate to the nature of the liquid.

3.2 Pump denomination

See Figure 2 (page 318) for an explanation of the

denomination code for the pump and one example.

3.3 Nameplate

The nameplate is a metal label that is located on the

pump body or on drive lantern depending on model.

The name plate lists key product specifications. For

more information, see Figure 1 (page 313)

The nameplate provides information regarding the

impeller and casing material, the mechanical seal

and their materials. For more information, see Figure

3 (page 328).

IMQ or TUV or IRAM or other marks (for electric

pump only)

Unless otherwise specified, for products with a mark

of electrical-related safety approval, the approval re-

fers exclusively to the electrical pump.

3.4 Pump description

• Connection dimensions according EN 733 (mod-

els 32-125…-200; 40-125…-250; 50-125…-250;

65-125…-315;80-160…-315; 100-200…-400;

125-250…-400; 150-315…-400).

• Volute casing pump with back pull out power

end.

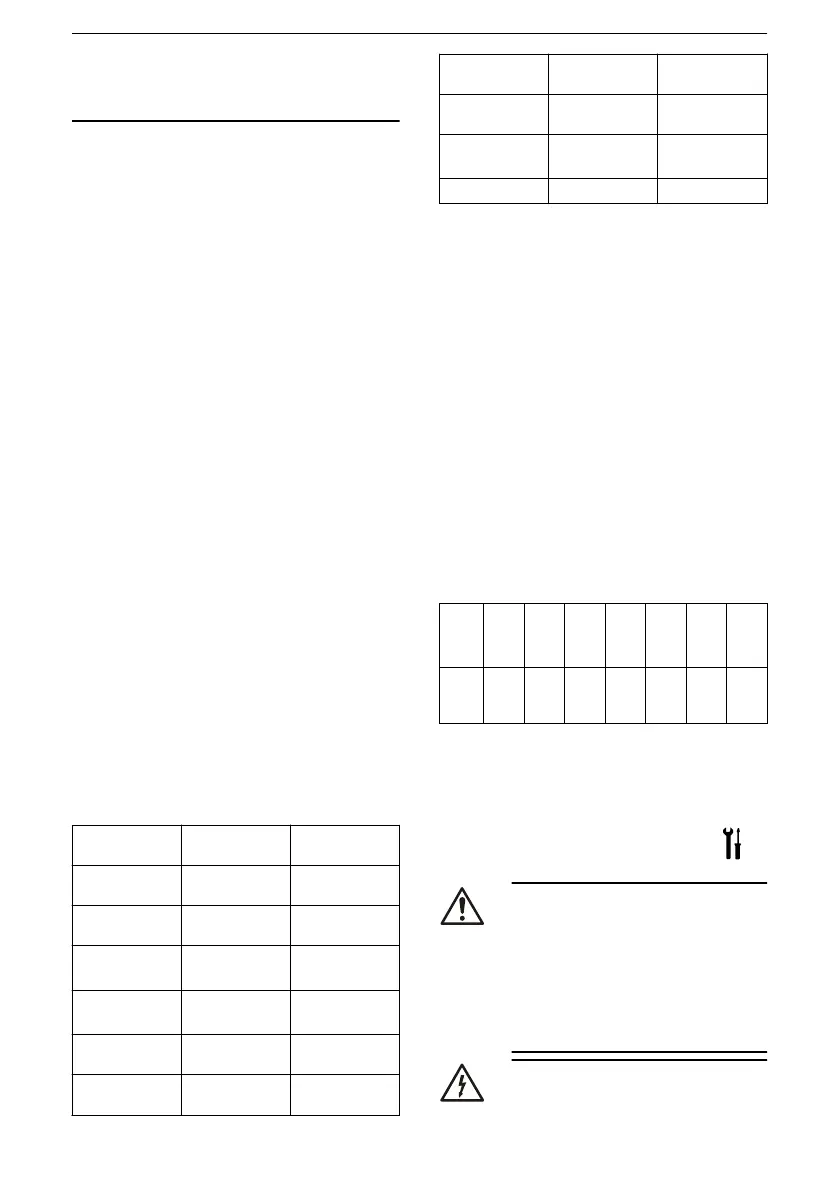

3.5 Material

The metallic parts of the pump that come in contact

with water are made of the following:

Material code Material cas-

ing / impeller

Standard/

Optional

CC Cast iron/Cast

iron

Standard

CB Cast iron/

Bronze

Standard

CS Cast iron/

Stainless steel

Standard

CN Cast iron/

Stainless steel

Standard

DC Ductil iron /

Cast iron

Standard

DB Ductil iron /

Bronze

Standard

Material code Material cas-

ing / impeller

Standard/

Optional

DN Ductil iron /

Stainless steel

Standard

NN Stainless steel /

Stainless steel

Standard

RR Duplex/Duplex Opzional

3.6 Mechanical seal

Unbalanced single mechanical seal acc. EN 12756,

version K.

3.7 Application limits

Maximum working pressure

Figure 4 (page

332) shows the maximum working

pressure depending on the pump model and the

temperature of the pumped liquid.

P

1max

+ P

max

≤ PN

P

1max

Maximum inlet pressure

P

max

Maximum pressure generated by the pump

PN Maximum operating pressure

Liquid temperature intervals

Figure 4 (page 332) shows the working temperature

ranges.

For special requirements, contact the Sales and

Service Department.

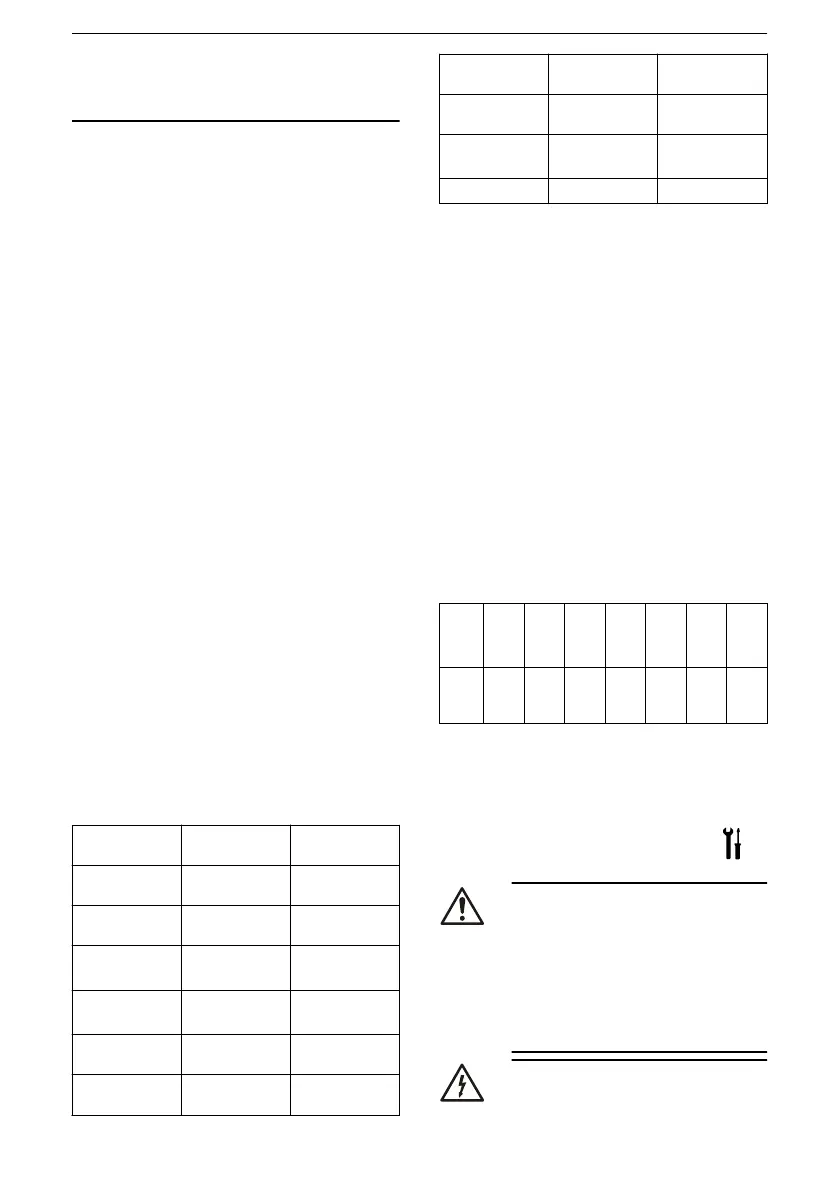

Maximum number of starts per hour

kW 0.25

-

3.00

4.00

-

7.50

11

-

15

18.5

22

30

-

37

45

-

75

90

-

160

Starts

per

hour

60 40 30 24 16 8 4

Noise level

For the sound pressure levels of pump equipped

with standard supplied motor

, see Table 7 (page

333).

4 Installation

Precautions

WARNING:

•

Observe accident prevention regula-

tions in force.

• Use suitable equipment and protec-

tion.

• Always refer to the local and/or na-

tional regulations, legislation, and co-

des in force regarding the selection of

the installation site, plumbing, and

power connections.

Electrical Hazard:

•

Make sure that all connections are

performed by qualified installation

en - Original instructions

16

Loading...

Loading...