Chapter 5 Positioning Instructions

5 - 49

5.3 Positioning Function Blocks (for XEC)

5.3.1 General for Function Block

In the XEC PLC, the input/output variables and their functions which are applied commonly for all the

function blocks used for internal positioning are as follows..

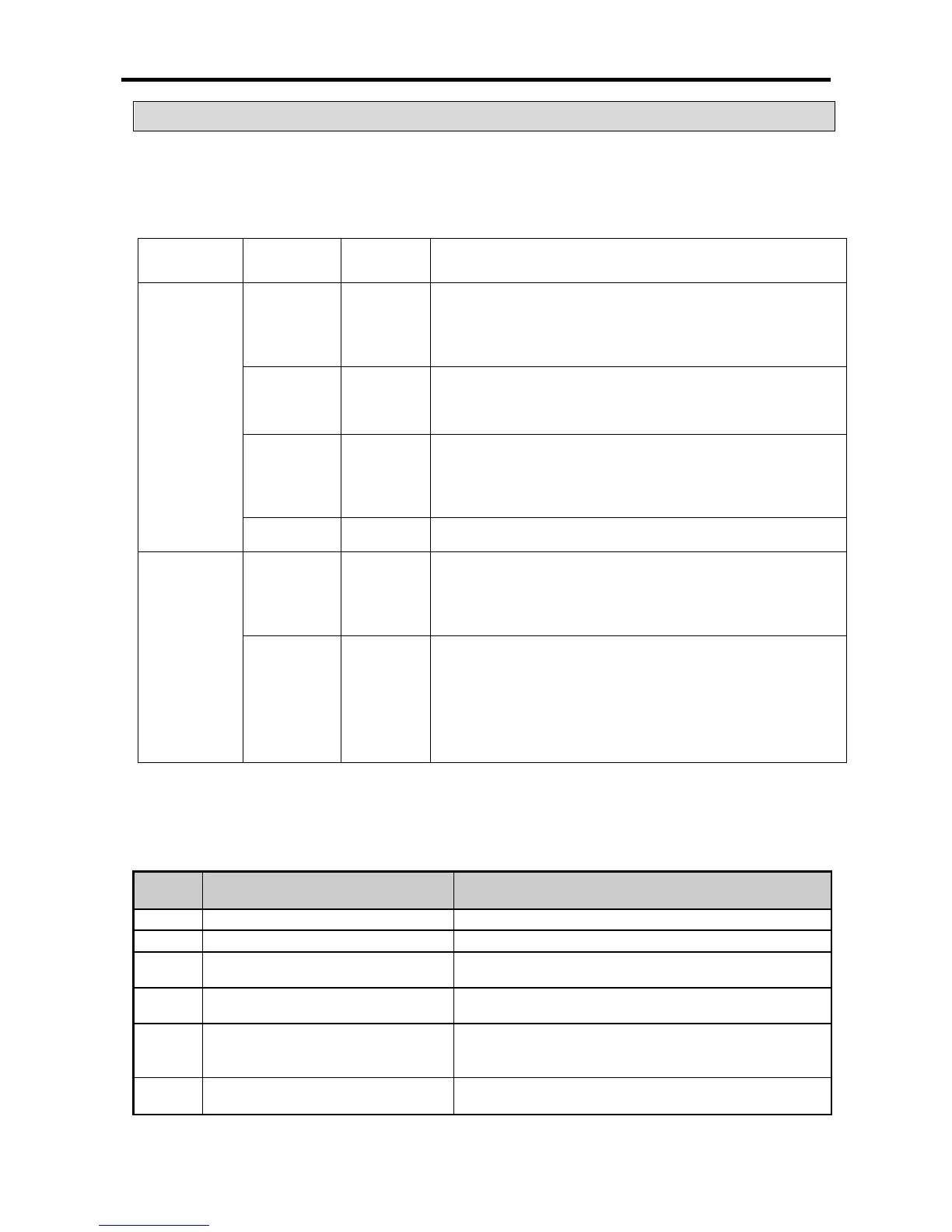

Classification Variable

Data Type Description

Input

Variables

REQ BOOL

•Request for function block execution

- If the condition in connection with this area is

satisfied during the software running and 0→1

(edge or level), the function block is executed.

- This area is for setting up the number of the base

where the positioning module is mounted. (In the

internal positioning of XGB, fix this to 0.)

- This area is for setting up the number of the slot

where the positioning module is mounted. (In the

internal positioning of XGB, fix this to 0.)

•Number of the axis in use

- X-axis: 0, Y-axis: 1

Output

Variables

DONE BOOL

•Indicates completion of the function block execution

- If the function block is executed without error,

“1” is outputted and maintained until the next

execution. If erroneous, “0” is outputted.

- This area indicates the number of the error

occurred in the start-up of the function block.

(The errors occurred during operation are

indicated in the K area which outputs error

Other I/O variables excluding the common variables presented in the above table are described

below.

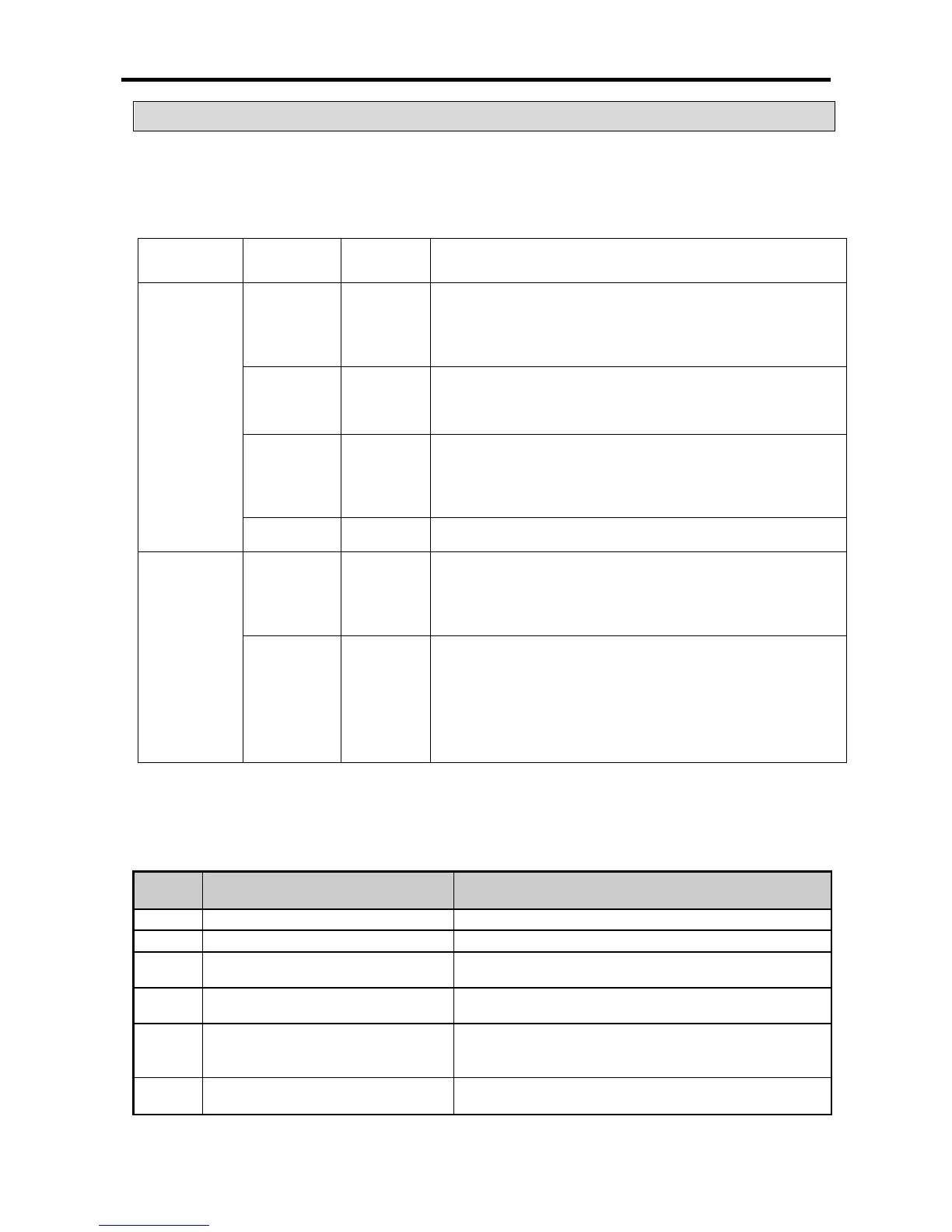

(1) Common Error Codes for Function Block

The types and description of the common error codes which may occur in the starting up of the function

blocks related with internal positioning are as follows.

Error

Error Type Countermeasures

0 Function block normally executed -

1 Base No. exceeded setting range Set the base No. to “0” for internal positioning.

3 Slot No. exceeded setting range Set the slot No. to “0” for internal positioning.

6 Axis range No. exceeded setting range

Adjust the axis No. within the allowable range of the

function block

(0: X-axis, 1: Y-axis)

10

A new function block was executed

while the previous instruction

Modify the program so that a new function block can be

executed after completion of the previous instruction.

11

Set-

up auxiliary input value exceeded

allowable range

Adjust the value within the allowable range.

For other error code, see “Appendix 1. Error Code List.”

Loading...

Loading...