MAINTENANCE AND SERVICING

Tightening Drive Wheel Nuts

At rst use, or when a wheel is removed, re-torque drive

wheel nut torque after one hour of operation.

Continue with torquing procedure at one hour intervals

of operation until two consecutive checks produce no

movement of the nuts.

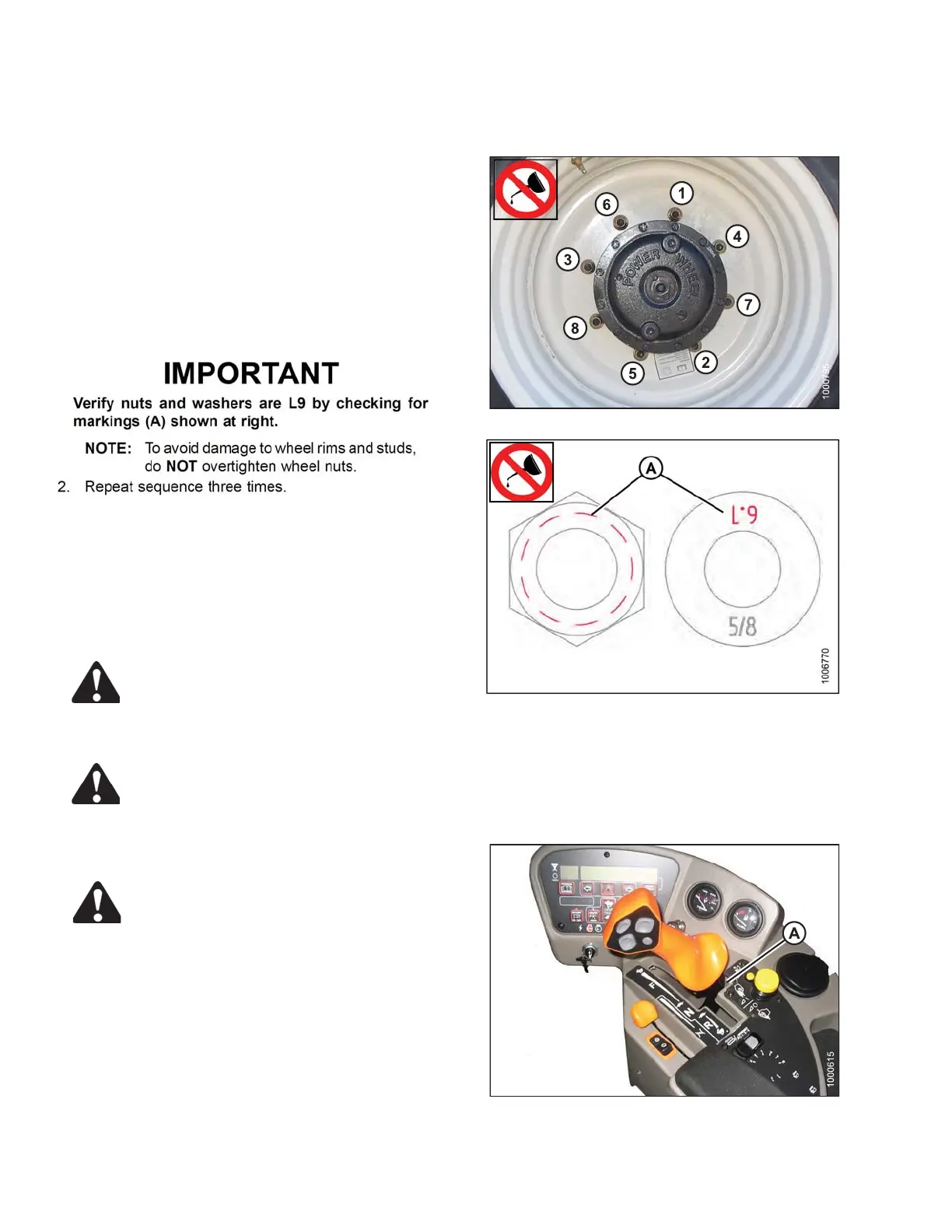

1.

Tightennutsto0ftlbf(0Nm)usingthetightening

sequenceasshown.

NOTE: Toavoiddamagetowheelrims,doNOT

overtighten wheel nuts.

Figure 5.199

Servicing Drive Wheel

Raising D

rive Wheel

This procedure can be used on both drive wheels.

DANGER

Stop engine and remove key from ignition before leaving operator's seat for any reason. A child or even

a pet could engage an idling machine.

CAUTION

HeaderMUST be removed, and NO weight box installed. Use a hydraulic jack with minimum lifting

capacityof5000lb(2268Kg)toprovideadequate

supportforthemachine.

CAUTION

Use a jack with minimum lifting capacity of 4000 lb

(1816 kg) to provide adequate support for the

machine.

1. Remove the header.

2. Park windrower on level ground and block all wheels.

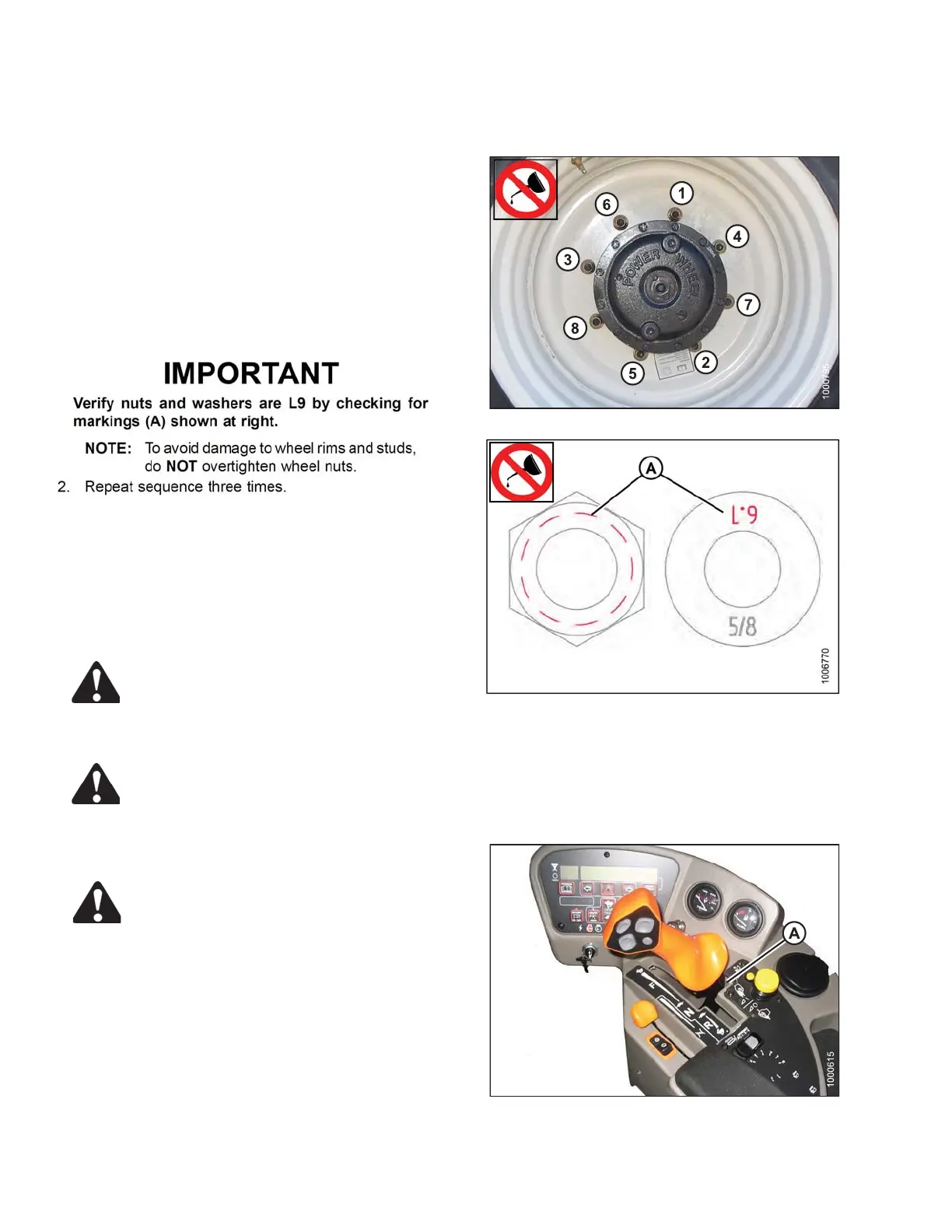

3. Place Ground Speed Lever (GSL) in N-DETENT (A),

shut down engine, and remove key.

Figure 5.200

169469 3

22

Rev. F

Replaces Page 322 in M205 Op Manual

Loading...

Loading...